Method for purifying and recycling methane and carbon dioxide from landfill gas and device thereof

A technology of carbon dioxide and landfill gas, which is applied in chemical instruments and methods, adsorption purification/separation, inorganic chemistry, etc., can solve problems such as waste, and achieve the effects of convenient operation, stable system, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

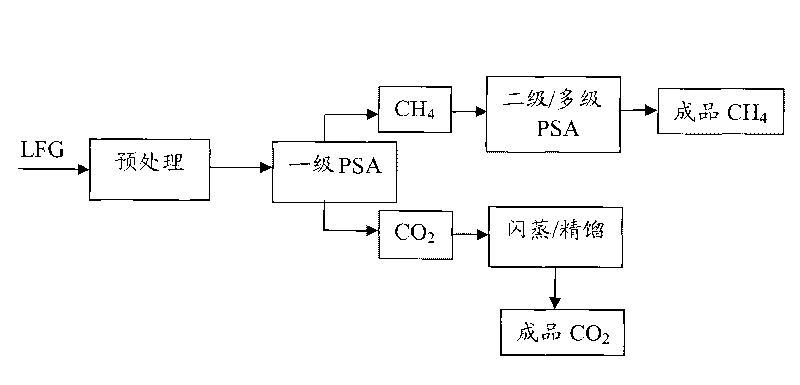

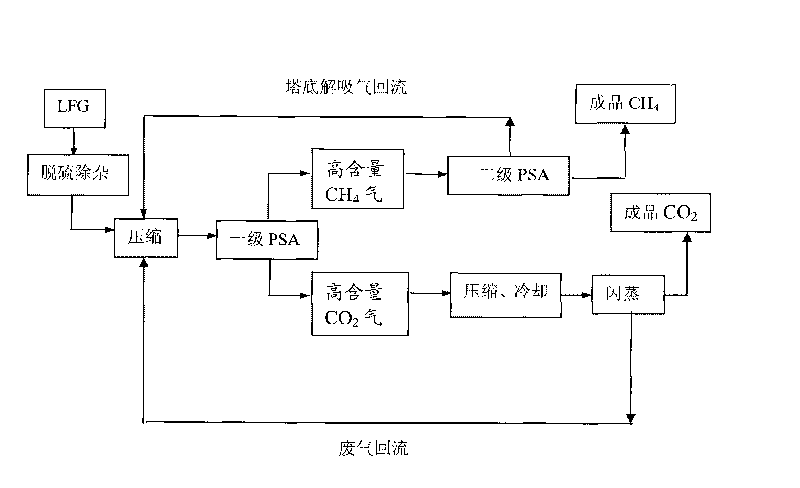

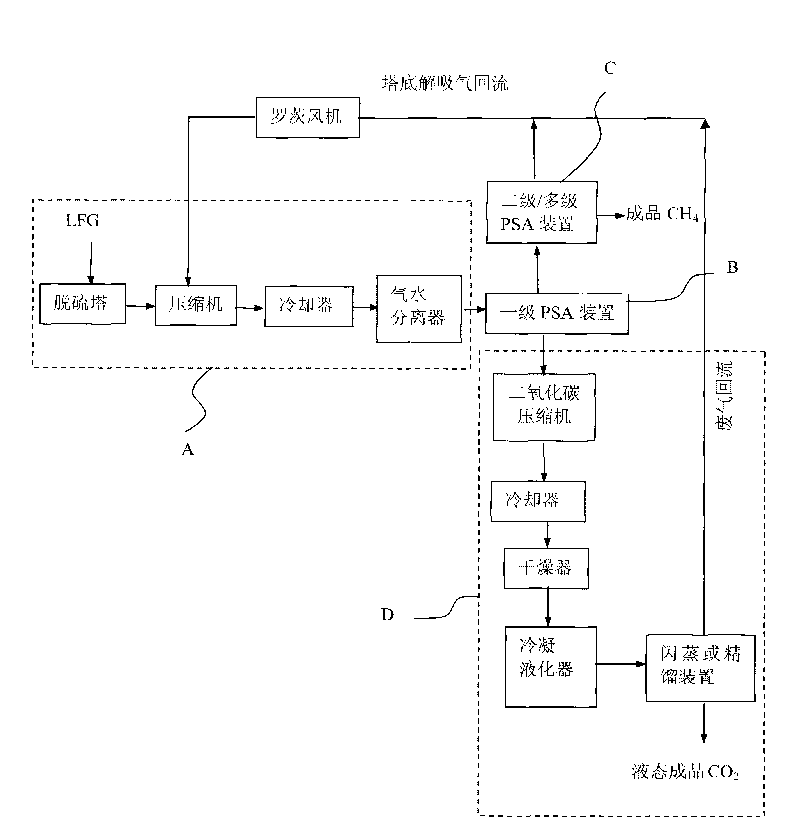

Embodiment 1

[0070] The landfill gas pretreated by desulfurization, compression, filtration, etc. enters the first-stage pressure swing adsorption unit. The adsorption pressure of high-pressure adsorption is 0.3MPa, and the adsorption time is 50s (seconds). The CH in the adsorbed gas obtained from the top of the tower 4 The content is 70% (the remainder is N 2 , O 2 ); then pressure equalization, reverse release, down to normal pressure, CO in the desorption gas obtained from the bottom of the tower 2 The content is 95.2% (the remainder is N 2 , O 2 and CH 4 ). The high content of CH flowing out of the top of the tower 4 The gas enters a two-stage / multi-stage pressure swing adsorption unit to obtain CH with a purity of 99.2% 4 Products, tail gas reflux; high CO content outflow from the bottom of the tower 2 The gas is compressed, cooled to liquefaction, enters the flash tank, and flashes to obtain 99.9% CO 2 Product gas, flash gas reflux.

Embodiment 2

[0072] After desulfurization, compression, filtration and other pretreatments, the landfill gas enters the first-stage pressure swing adsorption unit. The adsorption pressure of high-pressure adsorption is 0.3MPa, and the adsorption time is 150s. The CH in the adsorbed gas obtained from the top of the tower 4 The content is 72% (the remainder is N 2 , O 2 ); then pressure equalization, reverse release, down to normal pressure, CO in the desorption gas obtained from the bottom of the tower 2 The content is 95.2% (the remainder is N 2 , O 2 and CH 4 ). The high content of CH flowing out of the top of the tower 4 The gas enters a two-stage / multi-stage pressure swing adsorption unit to obtain CH with a purity of 99.1% 4 Products, tail gas reflux; high CO content outflow from the bottom of the tower 2 The gas is compressed, cooled to liquefaction, enters the flash tank, and flashes to obtain 99.9% CO 2 Product gas, flash gas reflux.

Embodiment 3

[0074] After desulfurization, compression, filtration and other pretreatments, the landfill gas enters the first-stage pressure swing adsorption unit. The adsorption pressure of high-pressure adsorption is 0.3MPa, and the adsorption time is 280s. The CH in the adsorbed gas obtained from the top of the tower 4 The content is 73% (the remainder is N 2 , O 2 ); then pressure equalization, reverse release, down to normal pressure, CO in the desorption gas obtained from the bottom of the tower 2 The content is 96% (the remainder is N 2 , O 2 and CH 4 ). The high content of CH flowing out of the top of the tower 4 The gas enters a two-stage / multi-stage pressure swing adsorption unit to obtain CH with a purity of 99.3% 4 Products, tail gas reflux; high CO content outflow from the bottom of the tower 2 The gas is compressed, cooled to liquefaction, enters the flash tank, and flashes to obtain 99.9% CO 2 Product gas, flash gas reflux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com