Colibacillus and method for performing soluble expression of transglutaminase proenzyme thereof

A technology of transglutaminase enzyme and glutaminase enzyme, which is applied in the field of transglutaminase genetic engineering, can solve the problems of cumbersome process, unstable production, easy degradation of high-yielding bacteria, etc., and achieves simple process and simplified fermentation. Production process, the effect of eliminating inclusion body denaturation and renaturation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

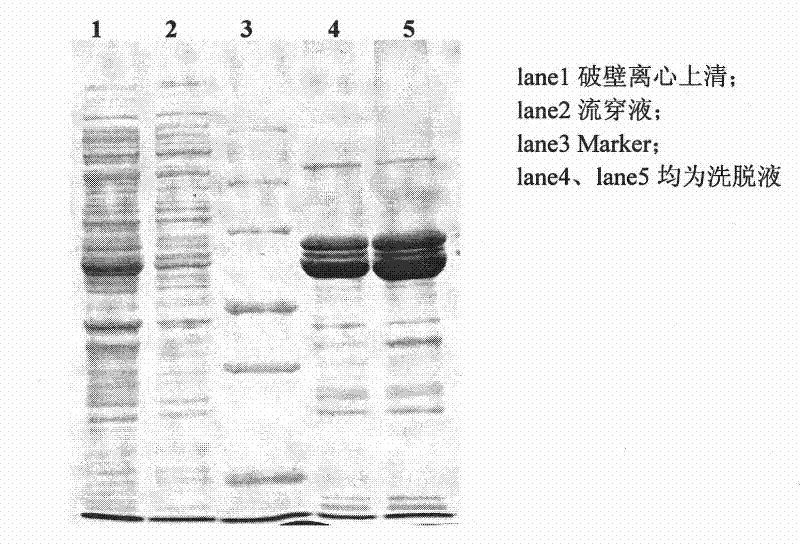

[0022] The construction process of engineering bacteria E.coli BL21 / proMTG and the method for soluble expression of transglutaminase zymogen under shake flask scale comprise the following steps:

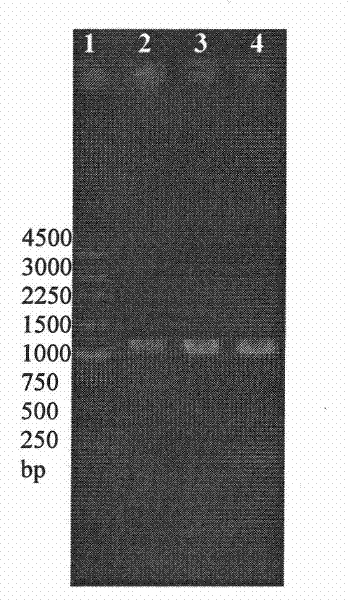

[0023] (1) PCR amplified transglutaminase zymogen gene: the nucleotide sequence of Maoyuan Streptomyces mobaraensis transglutaminase zymogen is from literature " Molecular Cloning of the Gene for Microbial Transglutaminase from Streptomyces mobaraensis and I

[0024] Construction of the expression plasmid: Obtain the gene fragment expressing the zymogen of transglutaminase, and clone it into the prokaryotic expression vector pET-22b(+) through NcoI and XhoI double enzyme digestion, construct the expression vector pET22-proMTG, and transform Escherichia coli BL21(DE3) became the engineering strain E.coli BL21 / proMTG.

[0025] (2) Escherichia coli fermentation process: inoculate the fresh single colonies of the above-mentioned Escherichia coli in 50mL LB medium (containing Amp 100μg / m...

Embodiment 2

[0027] Optimization of temperature for induction and expression of E. coli BL21 / proMTG:

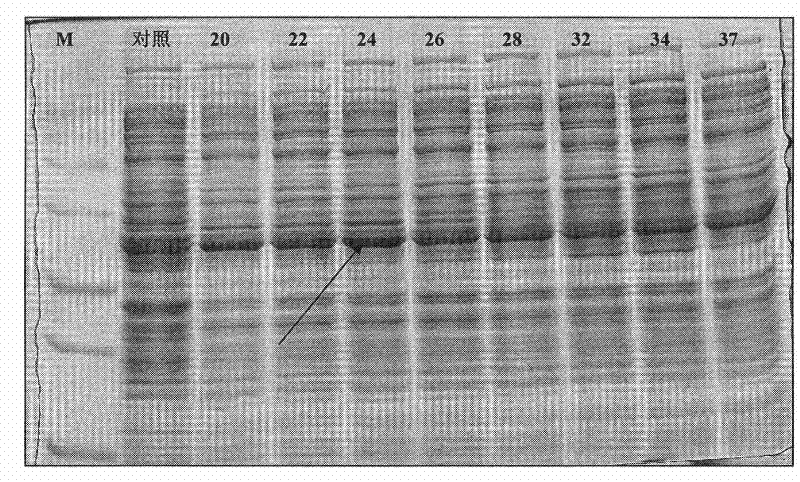

[0028] See Example 1 for the construction of Escherichia coli E. coli BL21 / proMTG. The single colony of the above-mentioned engineered bacteria was inoculated in 50mL LB medium, activated at 200rpm for 12h at 37°C, and then inoculated with 2% of the inoculum size in 100mL fermentation medium for 2h, then added IPTG to a final concentration of 1mM, and then inoculated at 20-37°C Induced expression was carried out under the conditions, centrifuged to collect cells after 6-8 hours, supernatant was obtained by ultrasonic crushing and centrifugation, the supernatant was activated with trypsin, and the activity of transglutaminase was measured by colorimetry, and it was found that under the condition of 20-28 ℃, all Soluble expression is formed in different degrees, and the expression level is the highest under the induction condition of 24°C. The SDS-PAGE electrophoresis images of the centrif...

Embodiment 3

[0030] Optimization of E. coli BL21 / proMTG inoculum volume:

[0031] See Example 1 for the construction of Escherichia coli E. coli BL21 / proMTG. A single colony of Escherichia coli E.coli BL21 / proMTG was inoculated in 50mL LB medium, activated at 37°C and 200rpm for 12h, and 1, 2, 3, 4mL of activated seeds were inoculated in 100mL fermentation medium and fermented to OD 600After =0.5 or so, add IPTG to a final concentration of 1 mM, and then place at 24°C to induce expression. After 4 hours, the cells were collected by centrifugation, ultrasonically broken and centrifuged to get the supernatant. After the supernatant was activated with trypsin, the activity of transglutaminase was measured by colorimetry. high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com