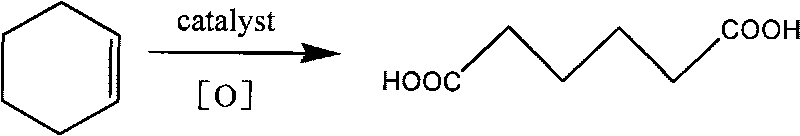

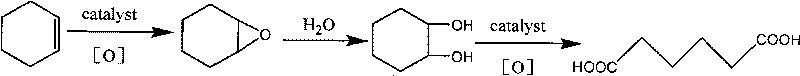

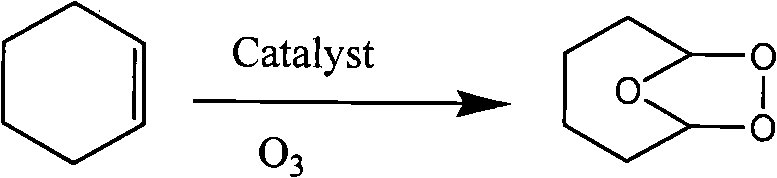

Method for synthesizing 3-alkenyl-1, 6-diacid by using electrochemical reaction

A chemical reaction and diacid technology, applied in the electrolysis process, electrolysis components, electrolysis organic production and other directions, can solve the problems of poor selectivity, difficult separation, unsuitable for industrialization, etc., and achieve low cost, good catalysis, and easy purification and separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Put 5.0mmol of tetramethylammonium bromide and 35mL of acetonitrile into a high-pressure electrolytic cell without a diaphragm lined with polytetrafluoroethylene, and feed 1,3-butadiene gas with a pressure of 2 standard atmospheres , when 7.0mmol 1,3-butadiene is dissolved into the high-pressure electrolyte (tetramethylammonium bromide and acetonitrile), the solution is saturated, and then carbon dioxide gas is introduced to make the pressure of the electrolytic cell 3MPa, with silver as the cathode, Aluminum is used as the anode, connected with 0.06A direct current, and the reaction stops when 2F of electricity per mole of 1,3-butadiene is passed through, and the reaction lasts for 6.3 hours.

[0047] (2) Filter the liquid in the electrolytic cell, keep the filtrate for recycling, vacuum-dry the filter residue at 80°C for 1 hour, add 50ml of hydrochloric acid solution with a mass fraction of 35% for acidification, stir for 4 hours, extract 3 times with 30ml of ether...

Embodiment 2

[0050] (1) Put 5.0mmol tetramethylammonium bromide, 35mL dimethyl sulfoxide, and 6.9mmol 2-methyl-1,3-butadiene into a high-pressure electrolytic cell without a diaphragm lined with polytetrafluoroethylene In the process, carbon dioxide gas is introduced again so that the pressure of the electrolytic cell is 1MPa, silver and aluminum are used as the cathode and anode, and a 0.06A direct current is connected, and the reaction stops when 2F of electricity is introduced per mole of 1,3-butadiene, and the reaction It took 6.2 hours.

[0051] (2) Filter the liquid in the electrolytic cell, keep the filtrate for recycling, vacuum-dry the filter residue at 80°C for 1 hour, add 50ml of hydrochloric acid solution with a mass fraction of 35% for acidification, stir for 6 hours, extract 3 times with 30ml of ether, and combine the extractions The final solution was evaporated to dryness to obtain the crude product, and the mixed solution of 50ml of dichloromethane and ethanol (20:1 by vol...

Embodiment 3

[0053] (1) Put 5.0mmol of tetramethylammonium bromide, 35mL of acetonitrile, and 6.9mmol of 2,3-dimethyl-1,3-butadiene into a high-pressure electrolytic cell without a diaphragm lined with polytetrafluoroethylene , and then pass in carbon dioxide gas, so that the pressure of the electrolytic cell is 3MPa, with silver and aluminum as the cathode and anode, connected with 0.06A direct current, and stop the reaction when 1F of electricity per mole of 1,3-butadiene is passed in, and the reaction is complete. 3 hours.

[0054] (2) Filter the liquid in the electrolytic cell, keep the filtrate for recycling, vacuum-dry the filter residue at 80°C for 1 hour, add 50ml of hydrochloric acid solution with a mass fraction of 35% for acidification, stir for 3 hours, extract 3 times with 30ml of ether, and combine the extractions The final solution was evaporated to dryness to obtain the crude product, and the mixed solution of 30ml dichloromethane and ethanol (20:1 by volume) was heated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com