High thickness beige electrostatic copying paper and production method thereof

An electrostatic copying and production method technology, applied in the field of papermaking, can solve the problems of strong dependence on forest resources, large consumption of fiber raw materials, unfavorable energy saving and consumption reduction, etc., and achieve the effects of saving raw material consumption, reducing stimulation, and protecting eyesight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The fiber pulp ratio is 20% bleached chemical softwood pulp, 30% bleached chemical broadleaf pulp and 50% APMP pulp. Use fourdrinier paper machine with sizer for paper production, add auxiliary materials and dyes, including calcium carbonate 100kg / ton of paper, cationic starch 10kg / ton of paper, brightener 1kg / ton of paper, AKD 10kg / ton of paper, retention aid 0.05kg / ton of paper, degasser 0.1kg / ton of paper, fungicide 0.3kg / ton Paper, dye 0.4kg / ton of paper and basic alumina (PAC) 2kg / ton of paper; the added surface treatment agent includes corn starch 45kg / ton of paper and starch modifier 0.2kg / ton of paper. This embodiment is a preferred implementation.

Embodiment 2

[0036] The fiber pulp ratio is 15% bleached chemical softwood pulp, 45% bleached chemical hardwood pulp and 40% APMP pulp. Papermaking is carried out on a fourdrinier paper machine with a sizer, adding auxiliary materials and dyes, including calcium carbonate 120kg / ton of paper, cationic starch 7kg / ton of paper, brightener 0.5kg / ton of paper, AKD 13kg / ton of paper, retention aid 0.03kg / ton of paper, degasser 0.2kg / ton of paper, fungicide 0.2kg / ton Ton of paper, dye 0.5kg / ton of paper and basic alumina (PAC) 3kg / ton of paper; the added surface treatment agent includes corn starch 40kg / ton of paper and starch modifier 0.3kg / ton of paper.

Embodiment 3

[0038] The fiber pulp ratio is 25% of bleached chemical softwood pulp, 45% of bleached chemical hardwood pulp and 30% of APMP pulp. Papermaking is carried out on a Fourdrinier paper machine with a sizer, and auxiliary materials and dyes are added, including calcium carbonate. 110kg / ton paper, cationic starch 5kg / ton paper, brightener 1kg / ton paper, AKD 10kg / ton paper, retention aid 0.03kg / ton paper, degasser 0.15kg / ton paper, bactericide 0.3kg / ton Paper, dye 0.3kg / ton of paper and basic alumina (PAC) 1kg / ton of paper; the added surface treatment agent includes corn starch 55kg / ton of paper and starch modifier 0.3kg / ton of paper.

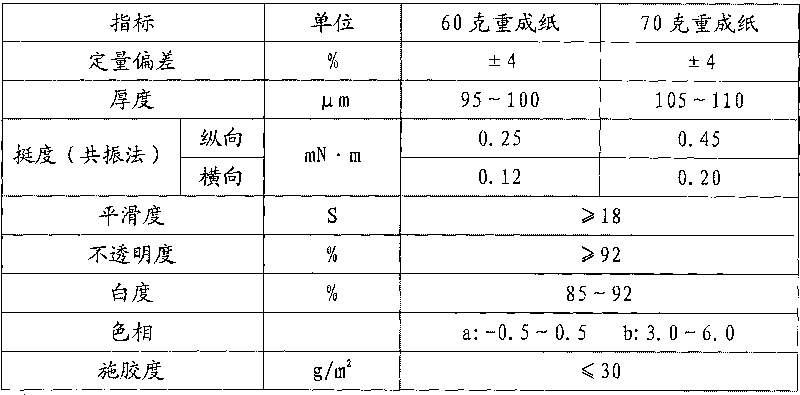

[0039] According to the high-thickness beige electrophotographic paper produced by the method provided by the invention, its main paper-forming index is as shown in table 1 below:

[0040] Table 1

[0041]

[0042] It can be seen that the 60-gram paper can replace the existing 70-gram electrostatic copy paper, and the 70-gram heavy paper can repl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Longitudinal stiffness | aaaaa | aaaaa |

| Lateral stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com