Integrative external wall heat insulating decorative board for inorganic cotton metal finish and preparation method thereof

A technology of external wall insulation and inorganic cotton, applied in climate change adaptation, covering/lining, construction, etc., can solve problems such as short service life, out-of-control construction quality, difficult maintenance, etc., to reduce engineering costs, reduce overall weight, simplify The effect of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

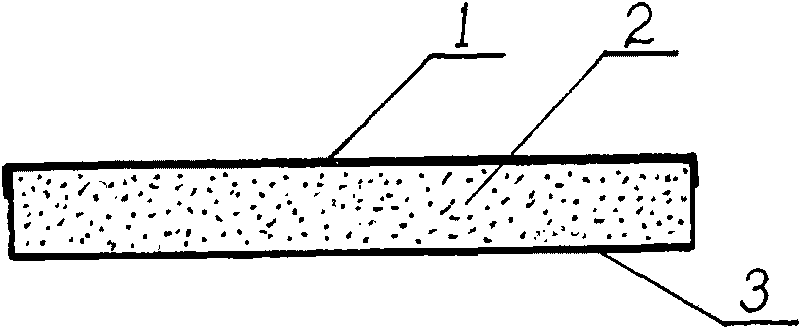

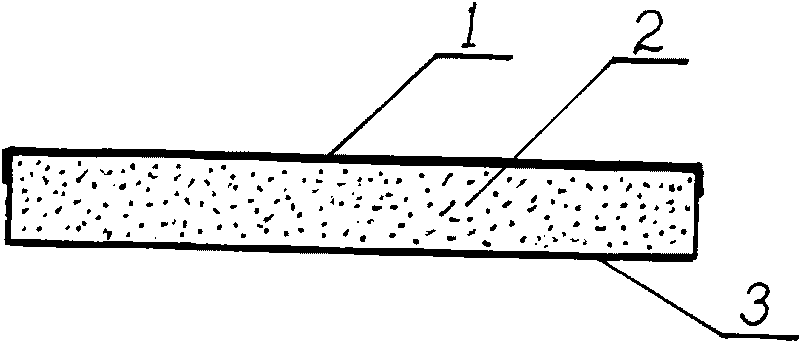

Image

Examples

Embodiment 1

[0031] The preparation of the inorganic wool metal facing integrated exterior wall thermal insulation decorative board of the present invention can be carried out according to the following steps:

[0032] 1) Take respectively according to the following proportions by weight: 6 parts of aluminum sulfate, 4 parts of aluminum phosphate and 2 parts of calcium stearate, put them in the reaction kettle, and press the total amount of three kinds of raw materials: water=1:1.5 weight ratio Add water, mix and stir evenly at a heating temperature of 90°C, and prepare inorganic salt composite cementing slurry for later use;

[0033] 2) Take any kind of inorganic wool among rock wool, glass wool, mineral wool and aluminum silicate wool, put it into the leavening machine for leavening, in the process of leavening, according to the inorganic wool: inorganic salt composite cementing slurry The volume ratio of material = 6: 1 is sprayed with inorganic salt caking slurry, and then sent to the ...

Embodiment 2

[0040] The preparation method of the inorganic cotton metal facing integrated exterior wall thermal insulation decorative board in this example is basically the same as that in Example 1, the difference is that:

[0041] The weight ratio of each raw material in step 1) is: 7 parts of aluminum sulfate, 5 parts of aluminum phosphate and 2.5 parts of calcium stearate, the weight ratio that adds water during mixing is three kinds of raw material total amounts: water=1: 2, heating The temperature is 95°C;

[0042] The volume ratio of inorganic cotton and inorganic salt composite cementing slurry in step 2) is: inorganic cotton: inorganic salt composite cementing slurry=7:1;

[0043] In step 3), the drying temperature of the wet body of the thermal insulation board is 190° C., and the drying time is 3.5 hours;

[0044] The metal plate in step 4) adopts titanium gold thin plate;

[0045] In step 5), the drying temperature of the thermal insulation and decorative composite board is ...

Embodiment 3

[0048] The preparation method of the inorganic cotton metal facing integrated exterior wall thermal insulation decorative board in this example is basically the same as that in Example 1, the difference is that:

[0049] The weight ratio of each component raw material in step 1) is: 8 parts of aluminum sulfate, 6 parts of aluminum phosphate and 3 parts of calcium stearate, the weight ratio that adds water during mixing is three kinds of raw material total amounts: water=1: 3 , the heating temperature is 100°C;

[0050] Step 2) The volume ratio of inorganic cotton and inorganic salt composite cementing slurry is: inorganic cotton: inorganic salt composite cementing slurry=8:1;

[0051] In step 3), the drying temperature of the wet body of the thermal insulation board is 180° C., and the drying time is 4 hours;

[0052] The metal plate in step 4) adopts titanium alloy thin plate;

[0053] In step 5), the drying temperature of the thermal insulation and decorative composite boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com