Method for pretreating catalyzer for making methanol or dimethyl ether into low-carbon olefin

A low-carbon olefin and catalyst technology, which is applied in the field of catalyst pretreatment, can solve the problem of deactivation and other problems, and achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

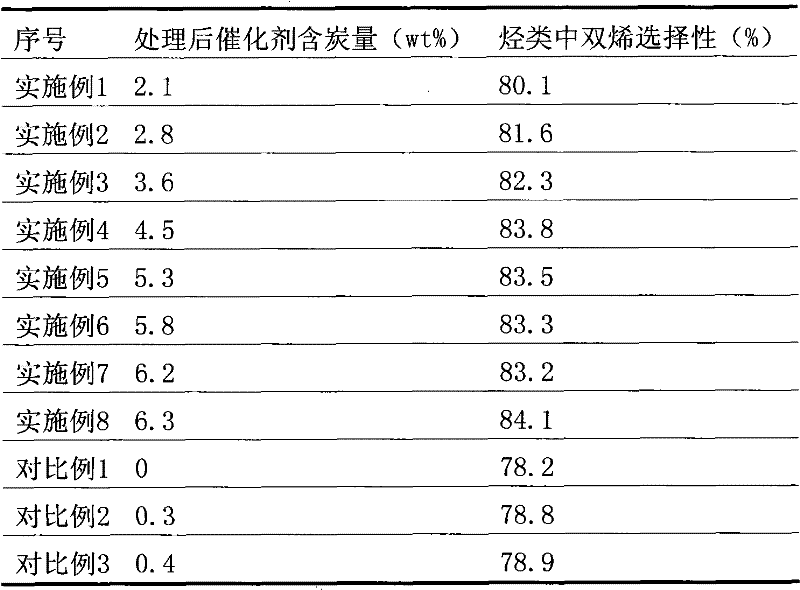

[0035] Catalyst pretreatment: Add 10g of fresh SAPO-34 catalyst into a fixed-bed reactor with an inner diameter of 30mm. Based on the weight of the catalyst, the initial carbon content of the catalyst is 0, the reaction temperature is 350°C, and the absolute pressure is 1MPa. First use high-purity N2 to purge for 30 minutes, the nitrogen flow rate is 100ml / min, and then add the pretreatment gas from the bottom of the pretreatment reactor. The composition of the pretreatment gas is ethylene, and its mass space velocity is 0.2 / h. 20min, and then purging with high-purity N2 for 30min, the carbon content of the treated catalyst is shown in Table 1.

[0036]Catalyst performance evaluation: Put the pretreated catalyst into a quartz tube fluidized bed reactor with an inner diameter of 20mm, maintain the reaction temperature at 450°C, and the absolute pressure at 0.15MPa. The raw material methanol is vaporized by the preheater and then passed into the reaction In the reactor, the mass...

Embodiment 2

[0038] Catalyst pretreatment: Add 10g of regenerated SAPO-34 catalyst into a quartz tube fluidized bed reactor with an inner diameter of 20mm. Based on the weight of the catalyst, the initial carbon content of the catalyst is 0.1%, and the reaction temperature is 450°C. Absolute The pressure is 0.15MPa, first purging with high-purity N2 for 30min, the nitrogen flow rate is 300ml / min, and then the pretreatment gas is added from the bottom of the pretreatment reactor, the composition of the pretreatment gas is propylene, and its mass space velocity is 1.5 / h , the feeding time continued for 8 minutes, and then purged with high-purity N2 for 30 minutes. The carbon content of the treated catalyst was shown in Table 1.

[0039] The catalyst performance evaluation method is the same as in Example 1, and the diene selectivity in the gas phase product is shown in Table 1.

Embodiment 3

[0041] Catalyst pretreatment: Add 10g of regenerated SAPO-34 catalyst into a quartz tube fluidized bed reactor with an inner diameter of 20mm. Based on the weight of the catalyst, the initial carbon content of the catalyst is 0.1%, and the reaction temperature is 500°C. Absolute The pressure is 0.15MPa, first purged with high-purity N2 for 30min, the nitrogen flow rate is 300ml / min, and then the pretreatment gas is added from the bottom of the pretreatment reactor. The composition of the pretreatment gas is 1-butene, and its mass space velocity is 2 / h, the feeding time continued for 5 minutes, and then purged with high-purity N2 for 30 minutes. The carbon content of the catalyst after treatment is shown in Table 1.

[0042] The catalyst performance evaluation method is the same as in Example 1, and the diene selectivity in the gas phase product is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com