Method and device for continuous conversion without stirring to produce sodium nitrate

A sodium nitrate, non-stirring technology, applied in the field of continuous conversion and production of sodium nitrate without stirring, can solve the problems of increasing the post-processing load and the difficulty of gas treatment, no gas-liquid separation of the converted gas, and insufficient oxidation reaction of the mother liquor. To achieve the effects that are conducive to automatic control, speed up the conversion reaction, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

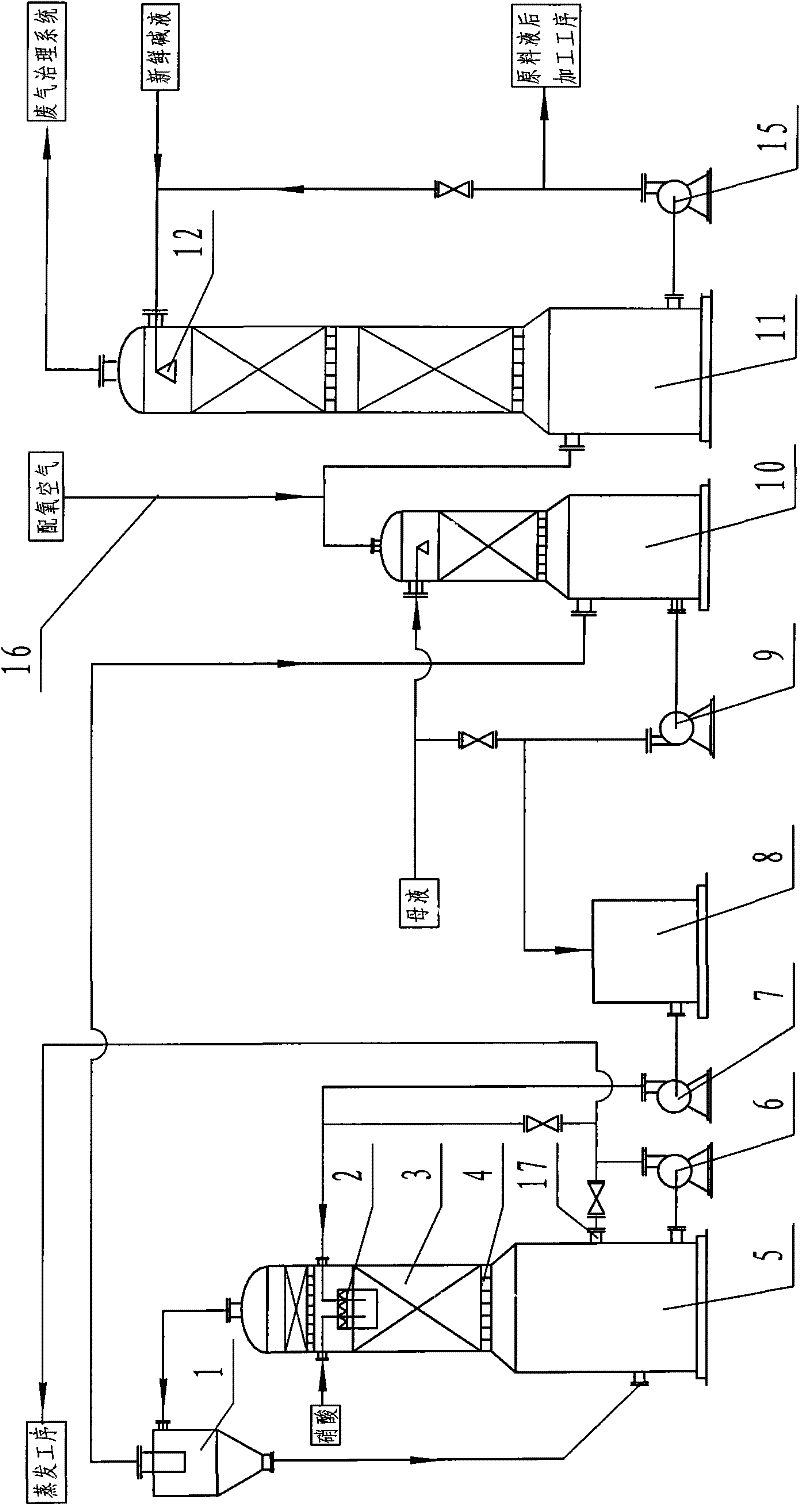

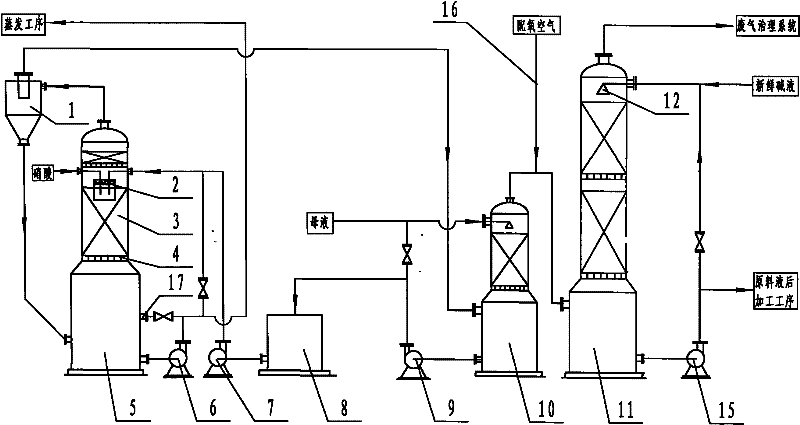

[0018] The non-stirring continuous transformation provided by the invention produces sodium nitrate device, as figure 1 As shown, it includes: ammonia oxidation preparation nitrogen oxide system, soda ash solution preparation system, sodium nitrite mother liquor conversion system, conversion liquid evaporation, crystallization, centrifugal separation system, packaging system and tail gas treatment system. The sodium nitrite mother liquor conversion system is mainly composed of a conversion tower 5, a pre-transformation tower 10, an absorption tower 11 and a mother liquor storage tank 8. The conversion tower, the pre-reformation tower and the absorption tower are packed towers, and the fillers are ceramic saddle-shaped fillers, and the lower part of the packing layer 3 of the packed tower is supported by a support grid 4 . The lower part of the tower is a liquid tank, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com