Preparation method of indium tin oxide nano powder

An indium tin oxide and nano-powder technology is applied in chemical instruments and methods, gallium/indium/thallium compounds, inorganic chemistry, etc., to achieve the effect of reducing high temperature and high pressure, simple preparation process, and easy industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

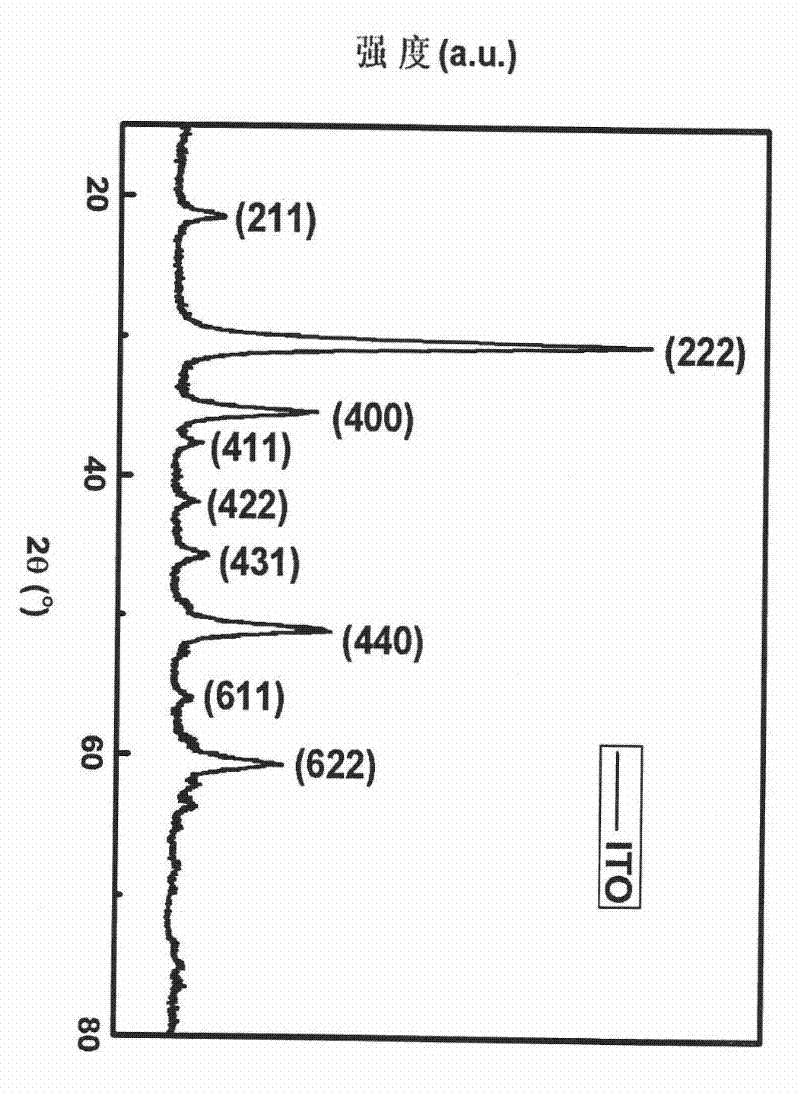

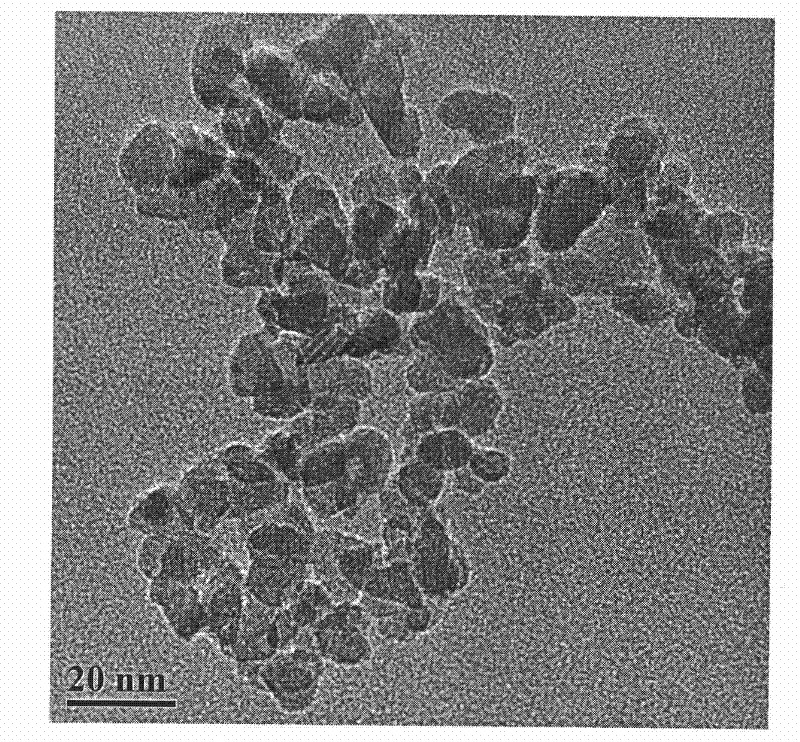

[0023] Weigh 0.1435g of tin chloride pentahydrate and 1.1732g of indium chloride tetrahydrate and dissolve them in 20ml of deionized water in a beaker, then add 20ml of ethylenediamine solution, and mix well. The mixed solution was transferred to a reaction kettle, reacted at 200° C. for 3 hours, and the reaction kettle was taken out to cool to room temperature to obtain an intermediate product. The intermediate product was centrifuged at 6000rpm for 20min, washed with deionized water until Cl-free - Washed twice with absolute ethanol, and the product was dried at 40°C for 24 hours to obtain an ITO precursor. The above-mentioned ITO precursor was put into a crucible and placed in a muffle furnace, and the temperature was raised from room temperature to 550 °C at a heating rate of 2 °C / min, kept for 1 h, and then cooled naturally to obtain ITO nanopowder. figure 1 For the X-ray diffraction pattern (XRD) of the ITO nano-powder prepared in this embodiment, it can be seen that t...

Embodiment 2

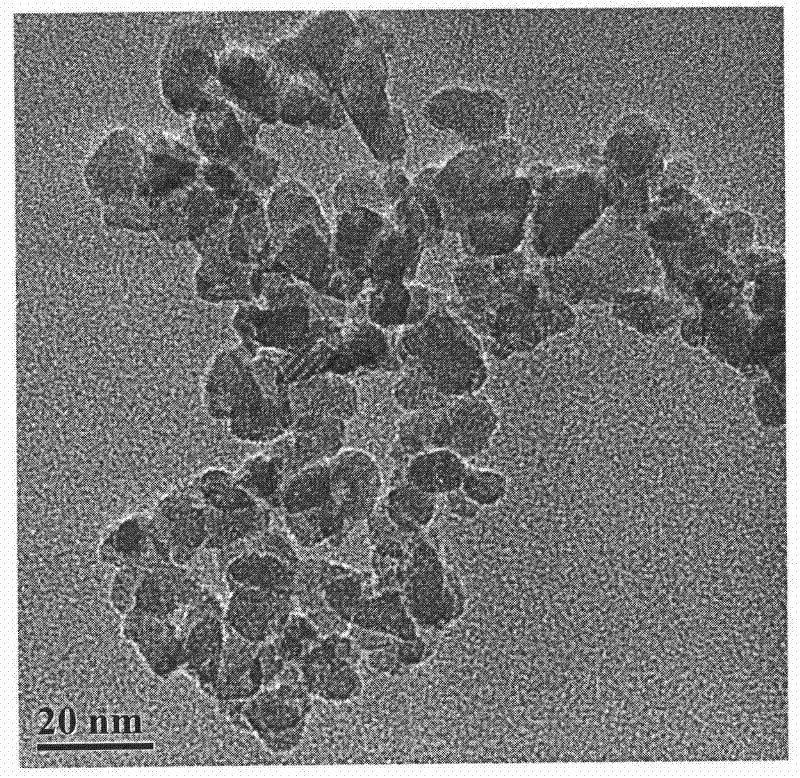

[0025] Weigh 0.1435g of tin chloride pentahydrate and 1.1732g of indium chloride tetrahydrate into a beaker and dissolve in 20ml of deionized water, then add 20ml of ethylenediamine solution and mix well. Transfer the mixed solution to a reaction kettle, react at 180°C for 5 hours, take out the reaction kettle and cool to room temperature to obtain an intermediate product. The intermediate product was centrifuged at 6500rpm for 15min, washed with deionized water until Cl-free - Washed once with absolute ethanol, and the product was dried at 50°C for 15 hours to obtain an ITO precursor. The above ITO precursor was put into a crucible and placed in a muffle furnace, and the temperature was raised from room temperature to 500°C at a heating rate of 4°C / min, kept for 1.5h, and then cooled naturally to obtain ITO nanopowder. XRD and EDS test results show that the nanocomposite material is ITO nanopowder material, and the grain size is 10.2nm calculated by Scherrer's formula. It c...

Embodiment 3

[0027] Weigh 0.2870g of tin chloride pentahydrate and 2.3464g of indium chloride tetrahydrate into a beaker and dissolve in 20ml of deionized water, then add 18ml of ethylenediamine solution and mix well. The mixed solution was transferred to a reaction kettle, reacted at 160° C. for 12 hours, and the reaction kettle was taken out to cool to room temperature to obtain an intermediate product. The intermediate product was centrifuged at 7000rpm for 10min, washed with deionized water until Cl-free - Washed three times with absolute ethanol, and dried the product at 60 °C for 10 h to obtain the ITO precursor. The above-mentioned ITO precursor was put into a crucible and placed in a muffle furnace, and the temperature was raised from room temperature to 450°C at a heating rate of 6°C / min, kept for 2h, and then cooled naturally to obtain ITO nanopowder. XRD and EDS test results show that the nanocomposite is ITO nanopowder material. The field emission scanning electron microscope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com