Method for preparing P type cobalt-doped zinc oxide film

A zinc oxide film and ceramic target technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of not mentioning that the film exhibits P-type semiconductor characteristics, etc., to achieve smooth surface and crystal quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

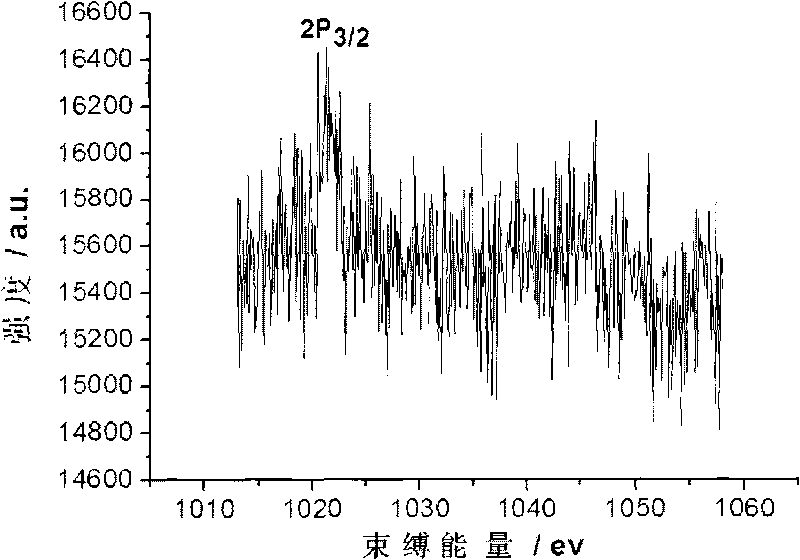

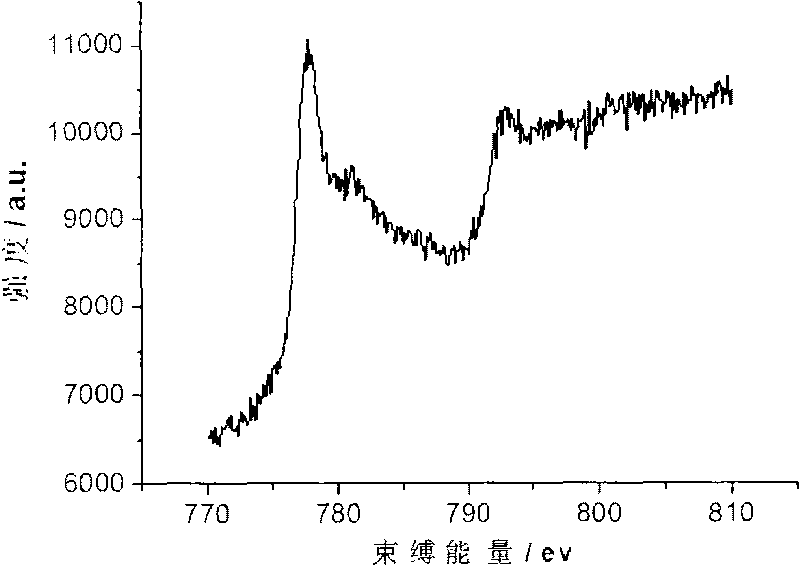

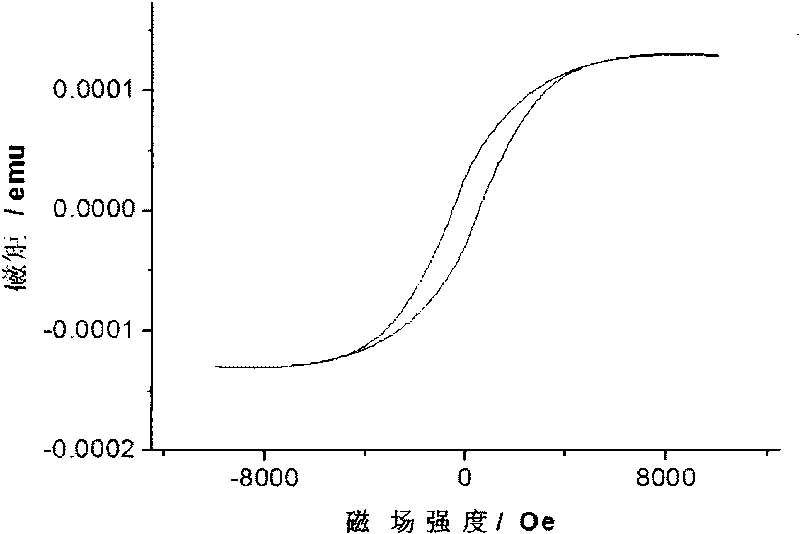

Image

Examples

Embodiment 1

[0019] 1) Preparation of Zn 0.9 co 0.1 O ceramic target:

[0020] 14.2621g of ZnO with a purity of 99.99% and 1.5297g of Co with a purity of 99.99% 2 o 3 (The molar ratio is 0.9:0.05) Put it into the agate grinder and grind for 3 hours, place it in a corundum sintering container, heat up to 1200°C within 5 hours and keep it warm for 6 hours, cool to room temperature, and grind it again in the agate grinder for 4 hours Finally, it is pressed into a solid circular target with a diameter of 30mm by a hydraulic target press (pressed at 12MPa for 3 minutes), and the solid circular target is placed in a tube furnace and kept at 1200°C for 11 hours to obtain a purity of 99.99%. Zn 0.9 co 0.1 O ceramic target;

[0021] 2) Preparation of P-type cobalt-doped zinc oxide film:

[0022] With the Zn prepared in step 1) 0.9 co 0.1 O ceramics as target material, with Al 2 o 3 The single crystal is used as the substrate, and the P-type cobalt-doped zinc oxide thin film is prepared b...

Embodiment 2

[0024] 1) with step 1) among the embodiment 1;

[0025] 2) In addition to vacuuming the vacuum chamber to 1.1×10 -4 Pa and heating the substrate to 700° C., other operations are the same as step 2) in Example 1.

[0026]

[0027] The Zn that table 1 embodiment 1-2 prepares 0.9 co 0.1 Hall effect detection results of O thin films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com