Extraction method of shark chondroitine

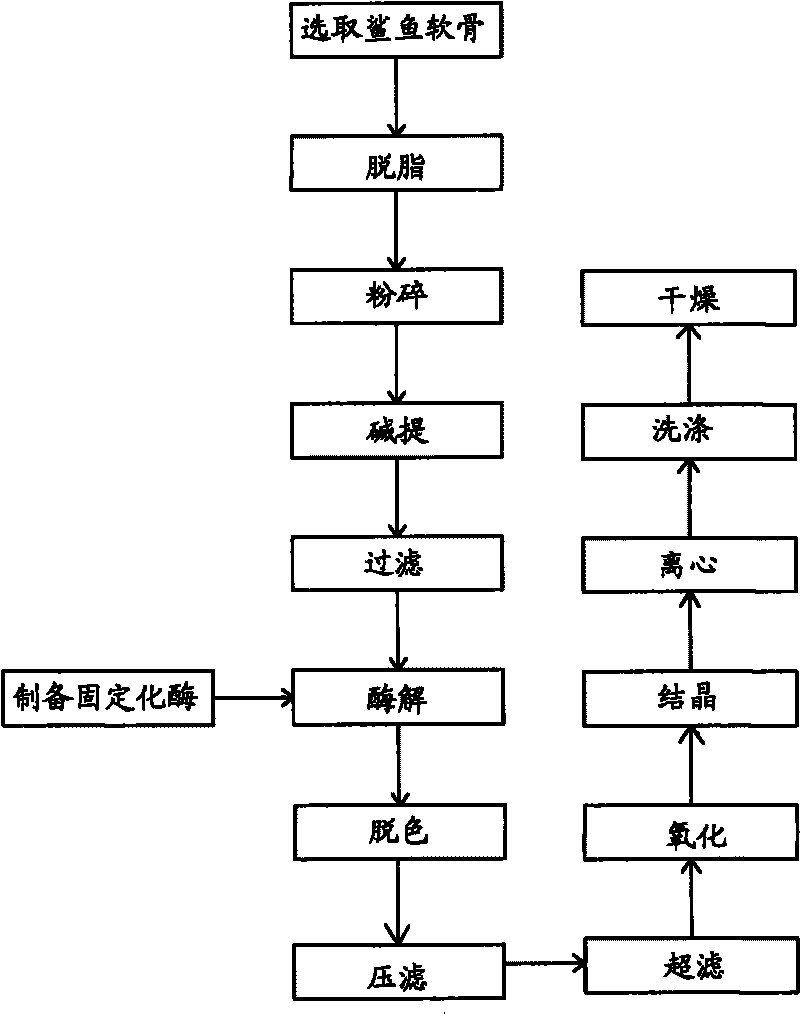

A chondroitin sulfate and extraction method technology, which is applied in the field of new bioengineering, can solve the problems that the enzyme cannot be used repeatedly, cannot be continuously produced, and the technical process is cumbersome, so as to achieve large-scale industrial production, easy operation, and simple technical process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Select 200g of shark head cartilage, cook in boiling water for 2-6 hours, rinse well, soak in ethanol or acetone for 30 minutes to remove oil. The degreased shark cartilage was broken into pieces, 800g of 5% NaOH solution and 800g of 3% salt solution were added, and the alkali extraction was intermittently stirred at a temperature of 20°C for 10 hours, filtered, and the residue was soaked in distilled water and filtered, combined Twice the filtrate and adjust the pH to 8.0 with HCl.

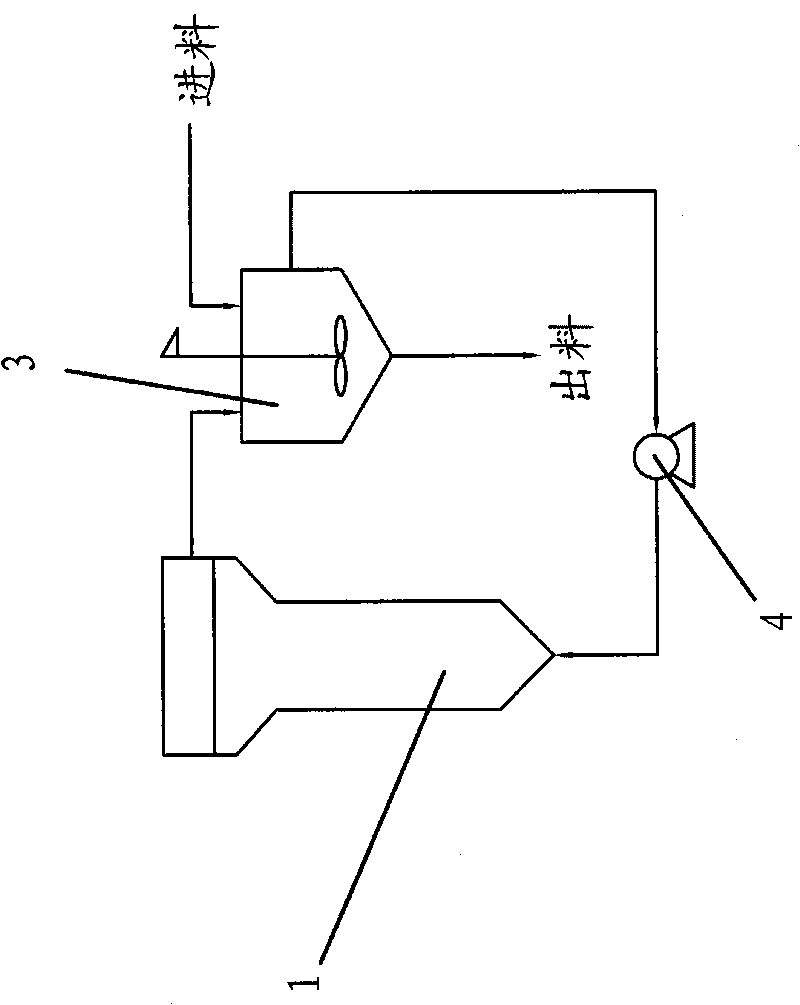

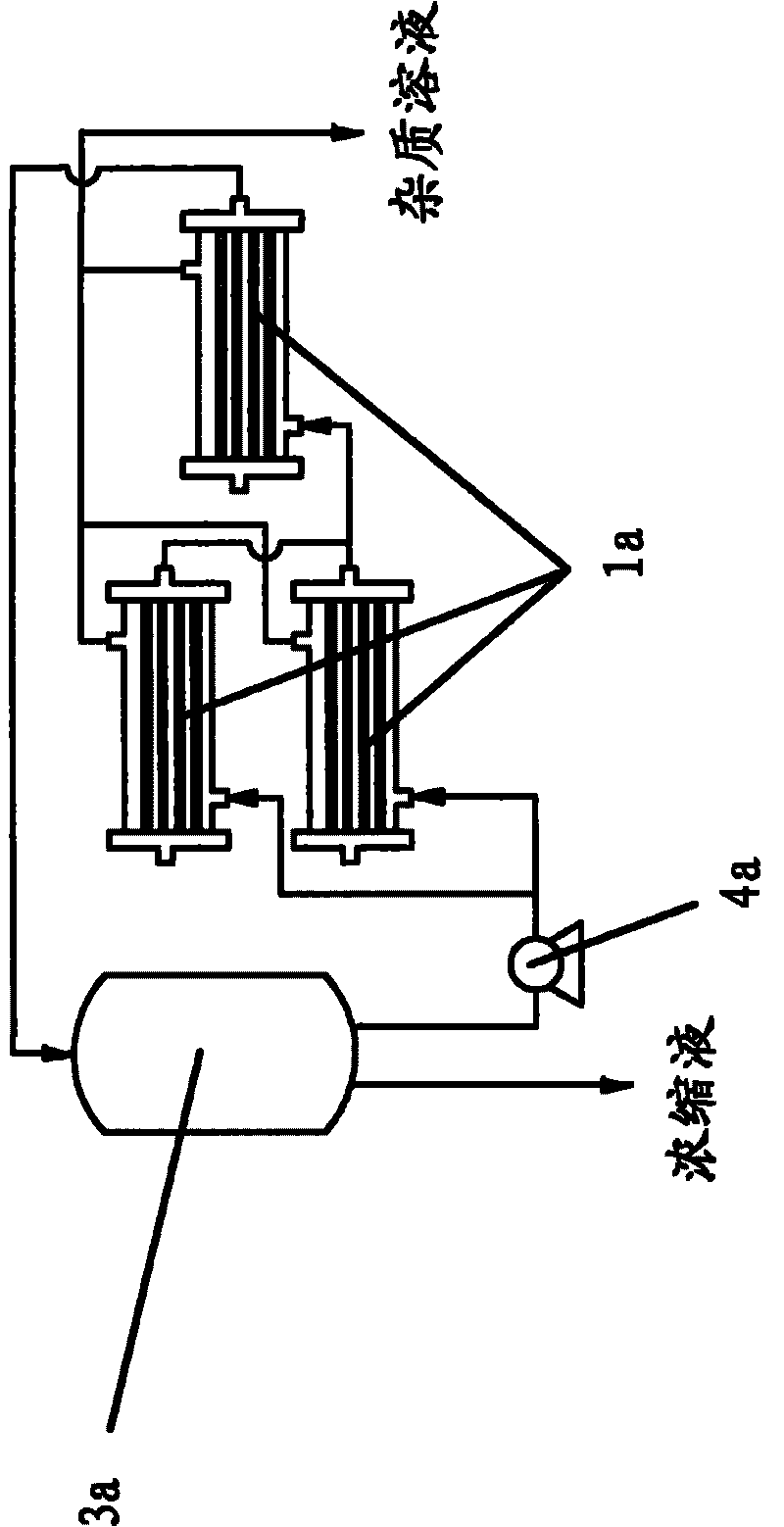

[0036] Papain was selected, and it was made into 4 g of immobilized papain by common cross-linking immobilization method. Among them, chitosan was used as carrier and glutaraldehyde was used as cross-linking agent for immobilization. Such as figure 2 As shown, in the fluidized bed reactor 1, immobilized papain is added, and the filtrate after alkali extraction is added to the enzymolysis circulation tank 3 and injected into the fluidized bed reactor 1 by the enzymolysis circulation pump...

Embodiment 2

[0044] Select 100g of shark tail cartilage and 100g of shark fin cartilage, cook in boiling water for 2-6 hours, rinse, soak in ethanol or acetone for 30 minutes to remove grease. The degreased shark cartilage is broken into pieces, add 1000g of 3% NaOH solution and 1000g of 2% salt solution, stir intermittently at 30°C for alkali extraction for 6 hours, filter, soak and filter the residue with appropriate amount of distilled water, and combine Twice the filtrate and adjust the pH to 9.0 with HCl.

[0045] Papain and subtilisin were selected and prepared into 4 g of immobilized papain and 2 g of immobilized subtilisin by ordinary embedding and immobilization methods, and packed into columns respectively. Among them, chitosan and sodium alginate were used as carriers for immobilization. The enzymatic hydrolysis process is the same as in Example 1, and will not be repeated. During the enzymatic hydrolysis, the pH was adjusted to 8.5 with sodium hydroxide solution. The new alk...

Embodiment 3

[0049] Select 50g of shark tail cartilage, 50g of shark vertebral cartilage, and 100g of shark fin cartilage, cook in boiling water for 2-6 hours, rinse well, and soak in ethanol or acetone for 30 minutes to remove grease. The degreased shark cartilage was broken into fragments, 1200g of 2% NaOH solution and 1200g of 1% salt solution were added, and the temperature was 40°C for intermittent stirring for alkali extraction for 3 hours, filtered, and the residue was soaked in distilled water and filtered, combined Twice the filtrate and adjust the pH to 8.5 with HCl.

[0050] Pepsin was selected, and it was made into 10 g of immobilized pepsin by common embedding and immobilization method. Among them, sodium alginate was used as the carrier for embedding and immobilization. The enzymatic hydrolysis process is the same as in Example 1, and will not be repeated. During the enzymatic hydrolysis, the pH was adjusted to 2.0 with hydrochloric acid solution. The new alkaline extract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com