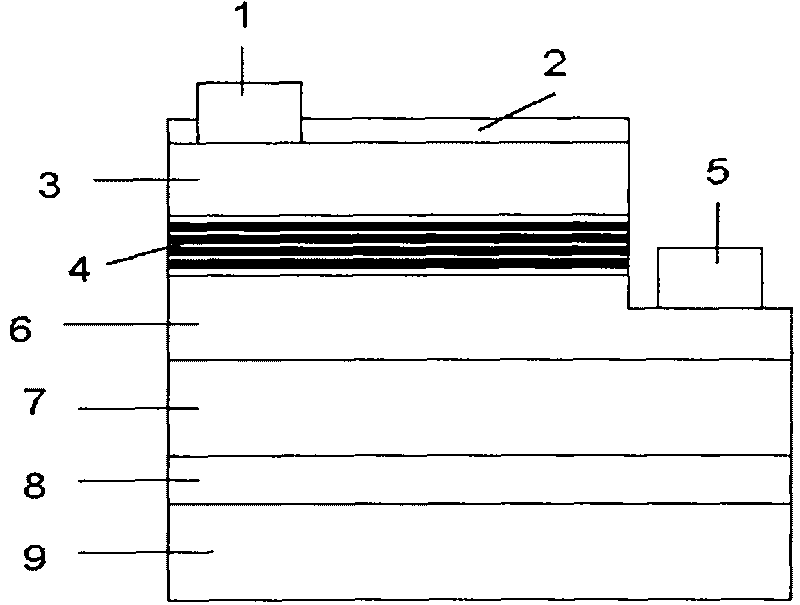

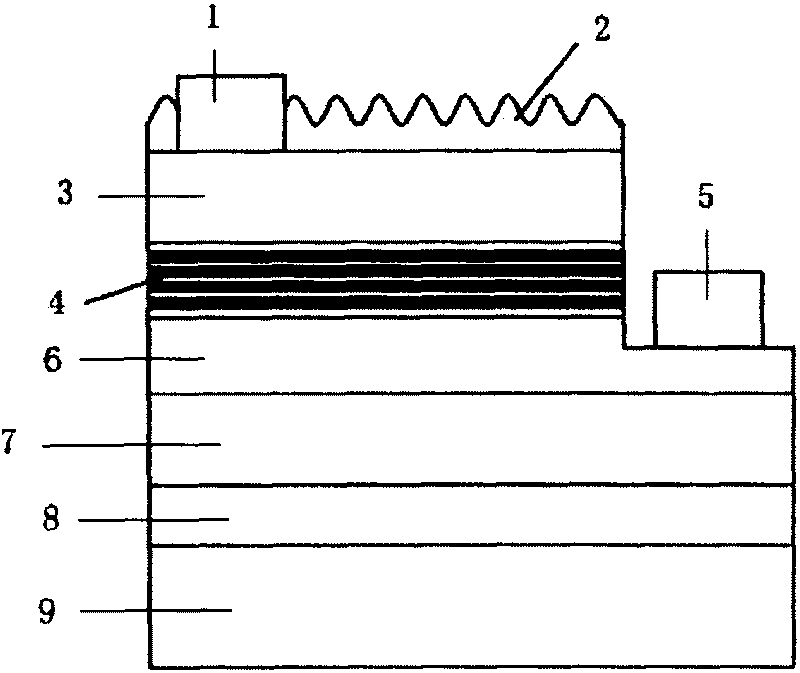

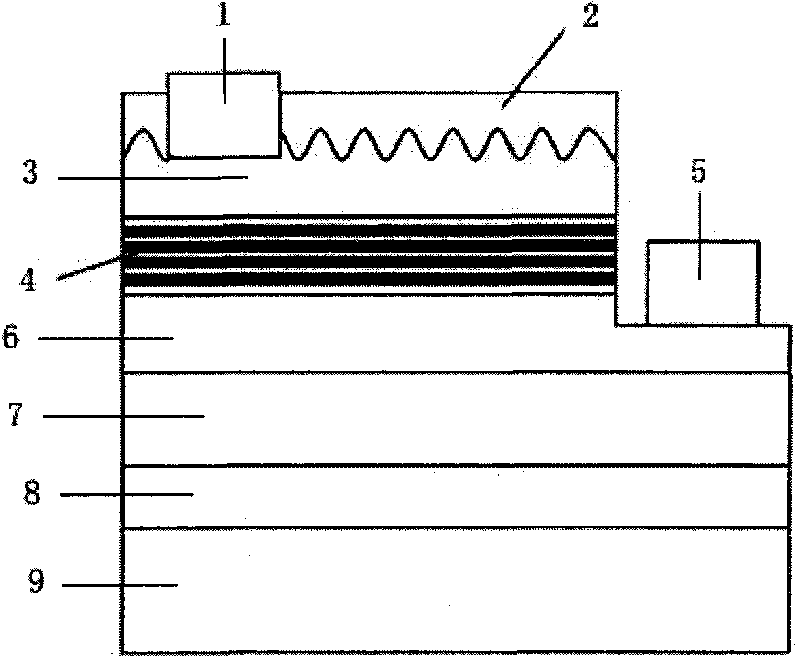

Surface roughening method of p-GaN layer or ITO layer in GaN-based LED chip structure

A LED chip and surface roughening technology, applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as difficult process control, high technical requirements, and increased forward bias voltage, and achieve easy process control, simple manufacturing process, The effect of increasing the probability of device surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for improving the light output rate of LED by roughening the surface of the ITO current spreading layer mainly includes the following steps:

[0033](1) Low-temperature GaN buffer layer, undoped GaN layer, n-GaN layer, multiple quantum well layer, p-GaN layer and evaporated ITO are sequentially grown on the semiconductor substrate by metal organic chemical vapor deposition (MOCVD) layered structure. Wherein the material of the semiconductor substrate is sapphire;

[0034] (2) Perform MESA photolithography and ICP etching on the grown epitaxial wafer until the n-type GaN is exposed;

[0035] (3) Electron beam deposition is used to deposit a layer of ITO thin film on the substrate after MESA lithography as the current spreading layer, and the thickness of the thin film is 350nm;

[0036] (4) Weigh 3g of nano-nickel particles into 30mL of ethanol, add 0.6g of citric acid, and ultrasonically disperse for 15min. If the surface of nickel nanoparticles is oxidize...

Embodiment 2

[0042] The method for improving the light output rate of GaN-based LEDs by roughening the surface of the p-GaN layer mainly includes the following steps:

[0043] (1) The low-temperature GaN buffer layer, undoped GaN layer, n-GaN layer, multi-quantum well layer, p-GaN layer and evaporated ITO are sequentially grown on the semiconductor substrate by metal-organic chemical vapor deposition (MOCVD) layered structure. Among them, the p-GaN layer is composed of a 10nm thick p-GaN layer and a 180nm thick magnesium-doped p-type GaN layer, and the material of the semiconductor substrate is silicon;

[0044] (2) Weigh 3g of nano-nickel particles in 30mL of ethanol, add 0.6g of oleic acid, and disperse ultrasonically for 10min. Before the dispersion is prepared, the surface of nickel nanoparticles is deoxidized, that is, the surface oxide of nano-nickel powder is removed. The specific operation is to put dilute hydrochloric acid (1:10) and nano-nickel powder into a beaker with a mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com