Alkaline zinc cell complex additive, preparation method thereof and application thereof

A composite additive, zinc battery technology, applied in the electrodes of primary batteries, dry cells, battery pack parts, etc., can solve the corrosion inhibition effect, the battery has a great impact on the working environment, does not meet the environmental protection, production and consumption concepts, alkaline zinc The problems of unfavorable sustainable development of batteries can reduce the production cost, simplify the production process, and improve the discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

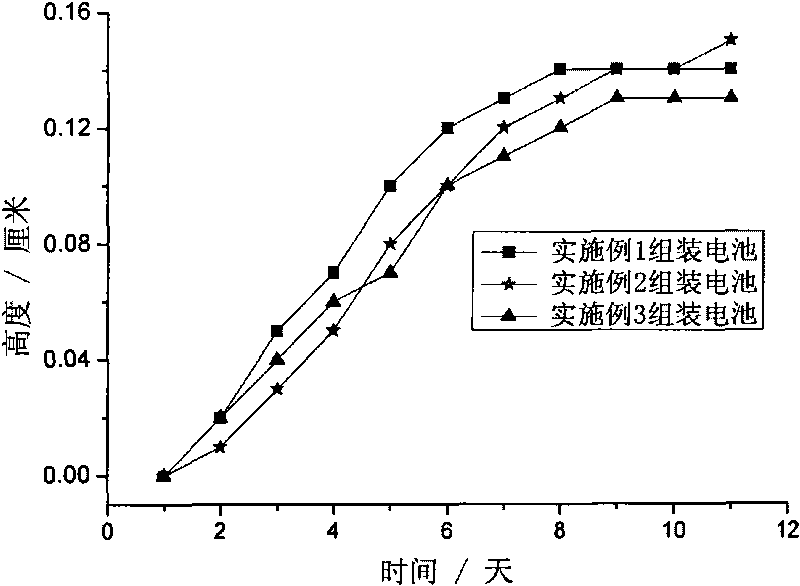

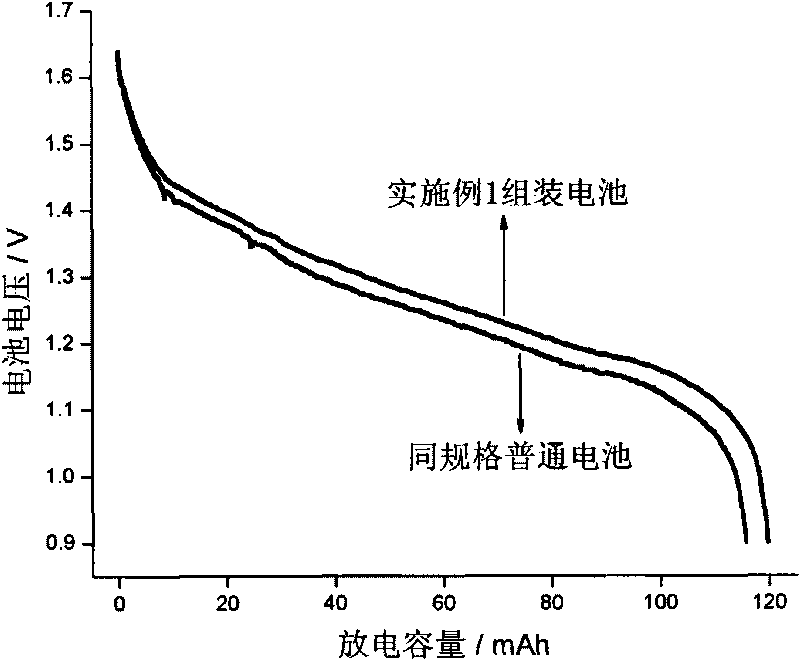

Embodiment 1

[0069] AG13 button-type alkaline zinc-manganese battery was prepared, and the specific operation process and materials used are shown in Table 1. Wherein the alkaline zinc battery composite additive used in the negative electrode solution is obtained by mixing imidazole and polyethylene glycol 600 in a mass ratio of 1:3; It is obtained by mixing at a mass ratio of 1:1.

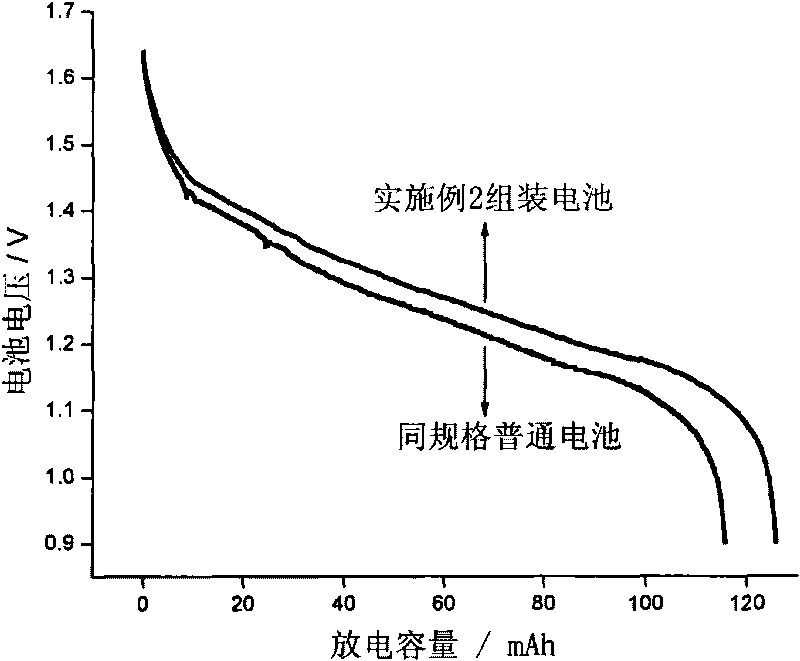

Embodiment 2

[0071] AG13 button-type alkaline zinc-manganese battery was prepared, and the specific operation process and materials used are shown in Table 1. Wherein the alkaline zinc battery composite additive used in the negative electrode liquid is obtained by mixing imidazole and polyethylene glycol 600 in a mass ratio of 1: 1; It is obtained by mixing at a mass ratio of 1:1.

Embodiment 3

[0073] AG13 button-type alkaline zinc-manganese battery was prepared, and the specific operation process and materials used are shown in Table 1. Wherein the alkaline zinc battery composite additive used in the negative electrode liquid is obtained by mixing imidazole and polyethylene glycol 600 in a mass ratio of 3: 1; It is obtained by mixing at a mass ratio of 1:1.

[0074] Table 1

[0075]

[0076]

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com