Method for synchronously purifying and separating organic extract of environmental medium step by step

A technology of environmental media and extracts, applied in the direction of material separation, analysis materials, measuring devices, etc., can solve the problems of differences in total extract components, incomparability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

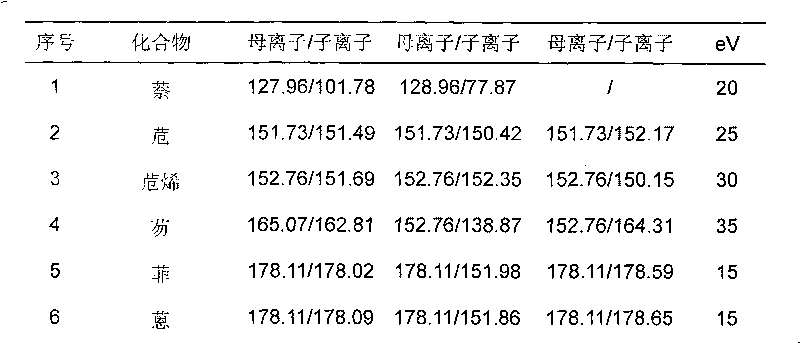

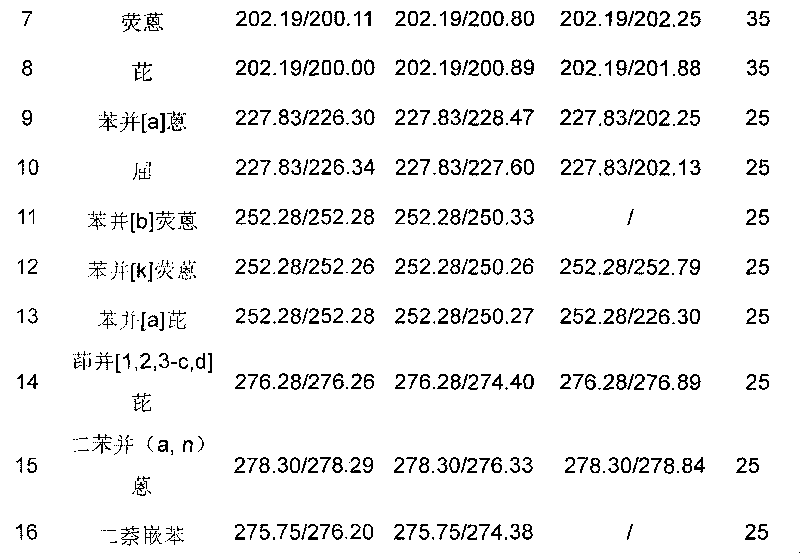

[0026]Accurately prepare 2L of simulated water samples containing certain concentrations of organic pollutants of different polarities (which contains 8 kinds of organochlorine pesticides (α-HCH, β-HCH, γ-HCH, δ-HCH, p , p'DDE, o, p'-DDT, p, p'-DDD, p, p'-DDT, the concentration is 20ng / L), 28 kinds of polychlorinated biphenyls (CB-8, CB-18, CB -28, CB-52, CB-44, CB-66, CB-81, CB-77, CB-101, CB-123, CB-118, CB-114, CB-105, CB-126, CB-153 , CB-138, CB-128, CB-167, CB-156, CB-157, CB-169, CB-187, CB-180, CB-170, CB-189, CB-195, CB-206, CB -209, the concentration is 20ng / L), 16 polycyclic aromatic hydrocarbons (naphthalene, acenaphthylene, acenaphthylene, fluorene, phenanthrene, anthracene, fluoranthene, pyrene, benzo[a]anthracene, chrysene, benzo[b]fluorene Anthracene, benzo[k]fluoranthene, benzo[a]pyrene, indeno[1,2,3-c,d]pyrene, dibenzo(a,n)anthracene, and perylene are all 20ng in concentration / L), and nonylphenol (200ng / L), octylphenol (200ng / L), bisphenol A (200ng / L), 17-β...

Embodiment 2

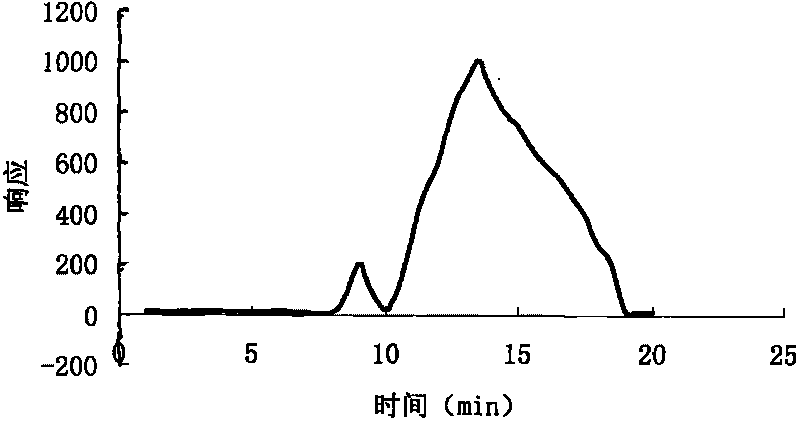

[0041] The method in Example 1 was used to configure, filter and enrich the water samples. The dried HLB column was eluted successively with 10mL n-hexane, 10mL n-hexane / dichloromethane (4:1) and 12mL methanol / dichloromethane (1:1) (flow rate 2mL / min), methanol / dichloromethane After 6 mL of the eluate was collected every 2 mL, it was concentrated to 0.1 mL in a gentle nitrogen flow, and analyzed by HPLC (DVD / FLD), the analysis conditions were as follows: - HPLC (DVD / FLD):

[0042] Mobile phase: 0-5min, methanol: water 80%: 20%; 5-11min, methanol 100%; flow rate: 1ml / min;

[0043] Column temperature: 30°C.

[0044] Detector:

[0045] BPA: FLD detector, λEx = 228nm;

[0046] E2: FLD detector, λEx = 224nm;

[0047] OP, NP: FLD detector, λEx = 226 nm.

[0048] The analysis results showed that when 10 mL of methanol / dichloromethane (4:1) was selected, the recovery rate of NP, OP, BPA, and E2 reached 90% to 110%, and the recovery rate did not increase significantly when the vol...

Embodiment 3

[0050] Put the bottom mud (soil and biological samples) in a refrigerator at -20°C to freeze, and then use a freeze dryer to remove water. After grinding, pass through a 200-mesh sieve and store in a refrigerator at 4°C. Take the ground mud (soil and biological samples) Sample) 20g sample was extracted three times with n-hexane, dichloromethane and methanol Soxhlet respectively (20 hours / time), and 1mL standard sample was added to the extracted soil (in which the concentration of OCs was 50ppb, PCBs was 50ppb, PAHs was 50ppb, phenolic compound is 50ppb), mixed thoroughly as a simulated sediment sample. Respectively with n-hexane / dichloromethane (1:1), n-hexane / dichloromethane (2:1) and n-hexane / dichloromethane ( 4:1) solvent as the extractant to extract the organic matter in the simulated sediment sample. After extraction, it is concentrated to 1mL to measure the concentration. The analysis conditions are as in Example 1 and Example 2. The results show that n-hexane / dichloromet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com