Biologic filtration method and device for purifying industrial organic waste gas

A technology of organic waste gas and biological filtration, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve the problems of affecting the biodegradation of functional microorganisms, cannot guarantee the treatment efficiency, and is not suitable for dealing with volatility, etc., and achieves stability. and efficient purification effect, improve stability and microbial diversity, avoid clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

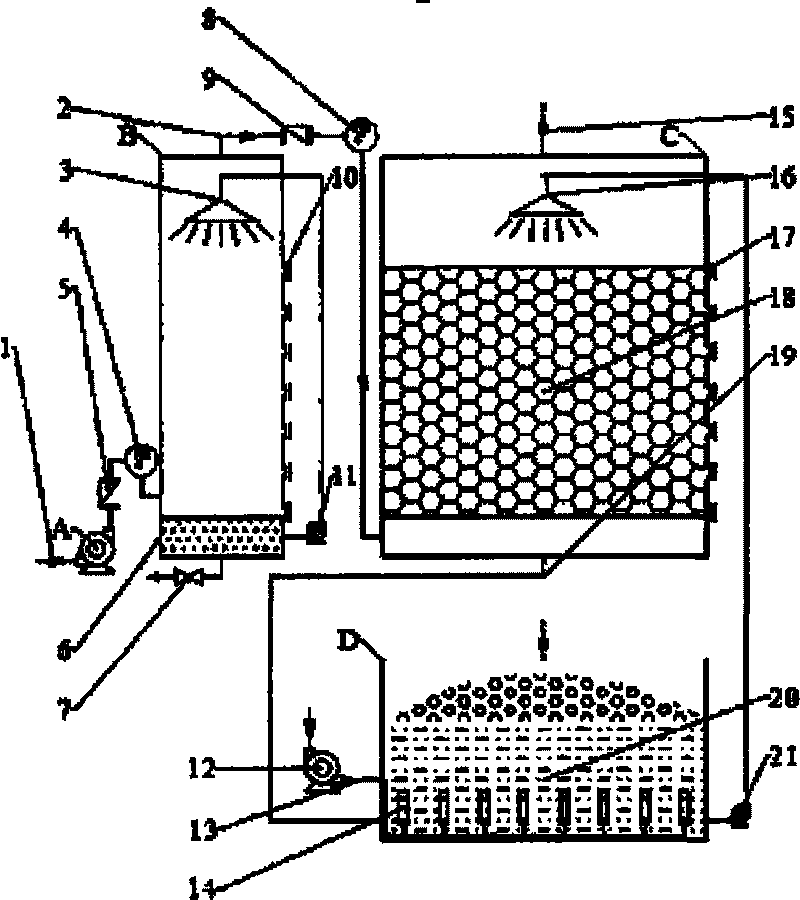

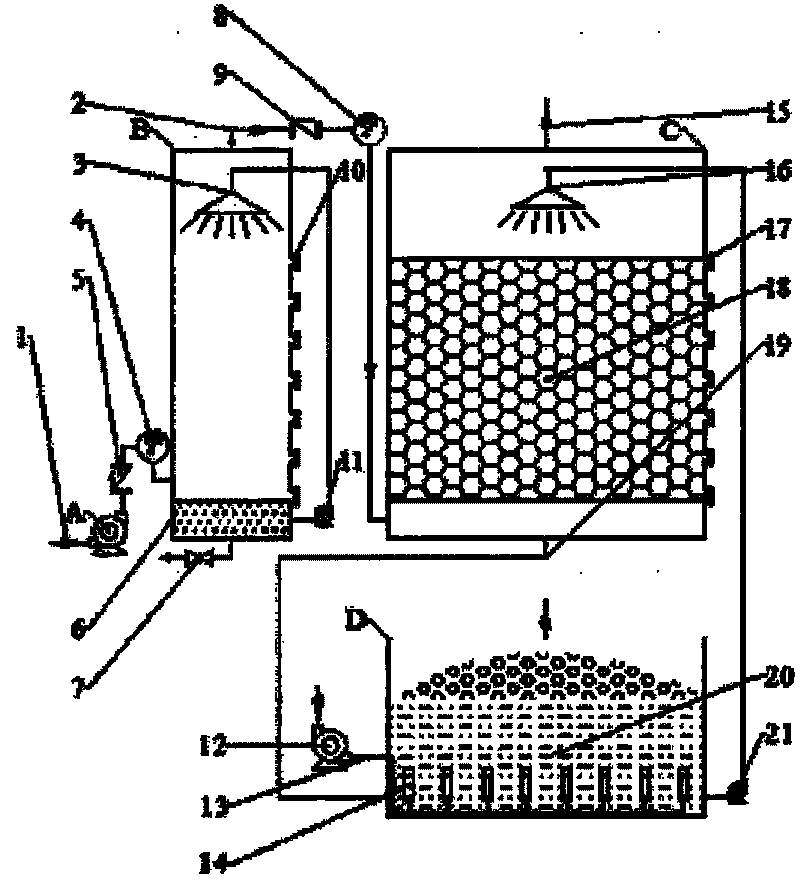

Image

Examples

Embodiment 1

[0064] Example 1: Treatment of waste gas from production workshops in the paint and coatings industry

[0065] The biological trickling filter tower C in this embodiment is 2000mm high, 1500mm long, 1500mm wide, and the packing height is 1200mm. The volume of the aeration tank is 0.5m 3 . The amount of industrial waste gas to be treated is 400m 3 / h, the residence time of the gas in the combined packing is 15 seconds. The biological filtration device is filled with combined filler and domesticated by degrading bacteria to form a film, and then used to treat the waste gas of the paint production workshop. When the average concentration of TVOCs (total volatile organic compounds) in the waste gas is about 58ppm, it drops to 3.48ppm after treatment. The average removal rate was 94%.

Embodiment 2

[0066] Example 2: Treatment of Common Industrial Waste Gas

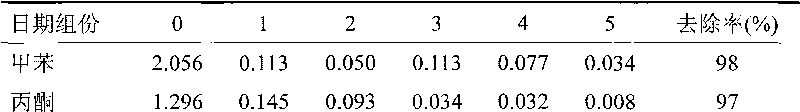

[0067] In this example, the biological trickling filter tower C is filled with combined inorganic fillers and used to treat common industrial waste gas components such as toluene, xylene, styrene, acetone, methyl ethyl ketone, and chloroform. The filling height is 340mm, and the volume of the aeration tank is 8L. The empty bed residence time of the gas in the combined packed bed is 30s. The processing effect is shown in Table 1:

[0068] Table 1 Purification effect of biological filtration devices on different common industrial waste gases (mg / m 3 )

[0069]

[0070]

[0071] The above results show that the method and device of the present invention are used to treat industrial organic waste gas, and the removal rate of common industrial waste gas is gradually increased. After 5 days, the removal rate of easily degradable volatile organic waste gas by the biological treatment device is between 98% and 100%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com