Pretreatment method before biochemical treatment of fermentation mother liquor

A biochemical treatment and pretreatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, heating water/sewage treatment, etc., can solve the problems of low daily treatment volume of mother liquor, high cost of powder spraying and drying, and high energy consumption , to achieve the effect of reducing the floor area of the plant, reducing equipment investment costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

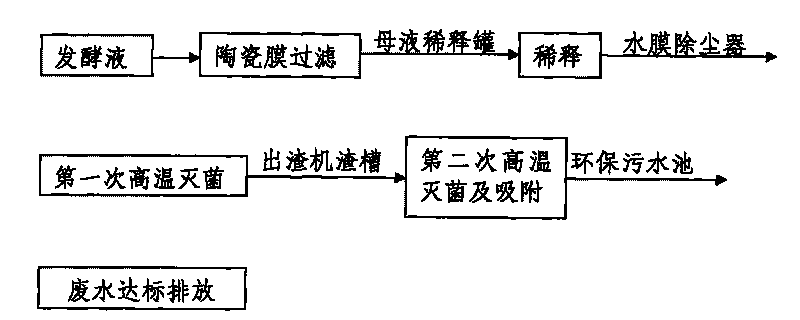

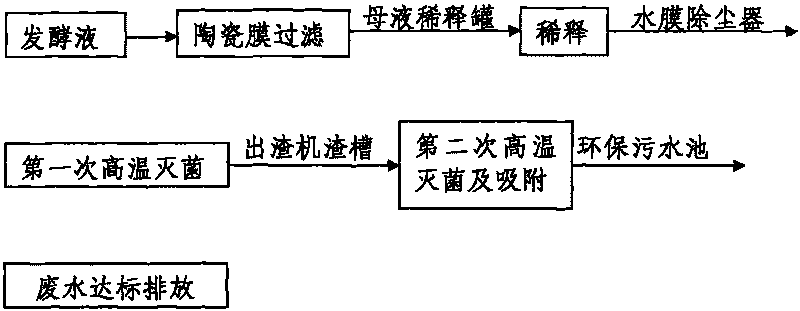

[0019] Such as figure 1 As shown, using the waste gas and waste residue produced by the SZL15-1.25AII industrial boiler to perform pretreatment on the fermented yeast liquid before biochemical treatment includes the following steps:

[0020] Take the waste fermentation liquid after producing vitamin C, and use the concentrated liquid filtered by ceramic membrane as yeast liquid. ℃.

[0021] A. Collect the above yeast liquid to 20M 3 In the mother liquor recovery pool, use a ZSW50-160 centrifugal pump to transport the fermented yeast liquid to two mother liquor dilution tanks (diameter 3300×5000mm), and dilute it according to the volume ratio of fermented yeast liquid and industrial water at 1:9. The industrial wastewater is Refers to recycled water that has passed environmental protection treatment, COD≤70mg / L.

[0022] B. Using an ISW50-160 centrifugal pump, replace the diluted yeast liquid with dust removal and cooling water, and transport it to the water film dust collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com