Off-line coated low-irradiation glass

A low-emissivity glass and glass plate technology, applied in the field of glass manufacturing and energy saving, can solve the problem of high production cost, and achieve the effects of improving productivity, dense film and high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

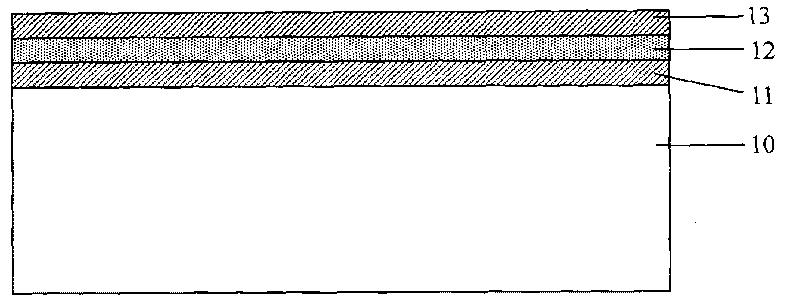

[0023] Embodiment 1: low-emissivity glass with a single silver layer structure, its structure is as follows: glass plate, first dielectric layer with a thickness of 45 nanometers, silver layer with a thickness of 10 nanometers, and second dielectric layer with a thickness of 54 nanometers. The dielectric layer adopts silicon-oxygen film, and the first dielectric layer adopts 3 sub-layers, each sub-layer has the same structure, the part with high silicon component has a refractive index controlled at 2.3, and the part with the lowest silicon component has a refractive index controlled at 1.5; The dielectric layer also adopts 3 sublayers, each sublayer has the same structure, the part with high silicon component has a refractive index controlled at 2.1, and the part with the lowest silicon component has a refractive index controlled at 1.5. The visible light transmittance of the low-emissivity glass exceeds 85%, the sunlight transmittance exceeds 65%, and the radiation coefficien...

Embodiment 2

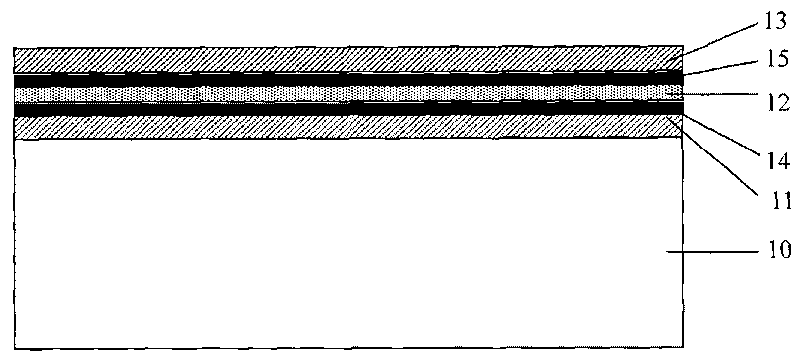

[0024] Embodiment 2: single silver layer structure low-emissivity glass, its structure is as follows successively: glass plate, the first medium layer of 39 nanometers thick, 2 nanometers thick titanium protection layer and interface improvement layer, 10 nanometers thick silver layer, 2 nanometers thick Thick titanium protective layer and interface improvement layer, 51 nanometer thick second dielectric layer. The dielectric layer is made of silicon-aluminum-oxygen thin film, and the atomic ratio of silicon to aluminum is 10:1. The first dielectric layer uses 3 sublayers, each sublayer has the same structure, and the refractive index is controlled at 2.3 for the parts with high silicon-aluminum components. For the part with the lowest component, the refractive index is controlled at 1.5; the second dielectric layer also uses three sublayers, each sublayer has the same structure, the part with the highest silicon-aluminum component has a refractive index of 2.3, and the part wi...

Embodiment 3

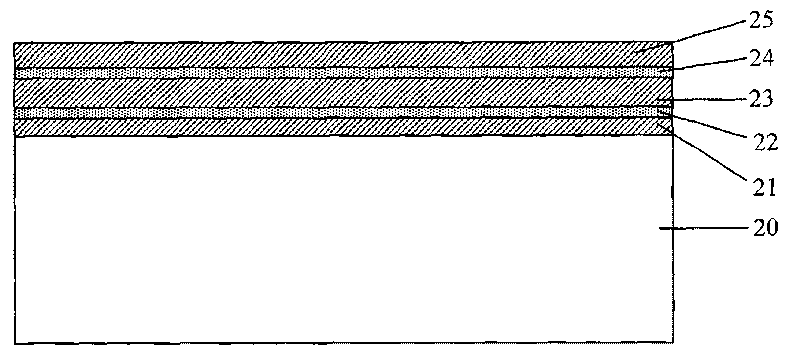

[0025] Embodiment 3: low-emissivity glass with a single silver layer structure, its structure is as follows: glass plate, first dielectric layer 36 nanometers thick, silver layer 10 nanometers thick, second dielectric layer 45 nanometers thick. The dielectric layer is made of silicon nitrogen thin film. The first dielectric layer uses 3 sublayers, each sublayer has the same structure. The part with the highest silicon component has a refractive index of 2.6, and the part with the lowest silicon component has a refractive index of 2.0; the second The dielectric layer also adopts 3 sublayers, each sublayer has the same structure, the part with the highest silicon component has a refractive index controlled at 2.3, and the part with the lowest silicon component has a refractive index controlled at 2.0. The visible light transmittance of the low-emissivity glass exceeds 85%, the sunlight transmittance exceeds 65%, and the radiation coefficient is less than 0.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com