Method for measuring electroactive area of three-dimensional porous membrane electrode

A three-dimensional porous and membrane electrode technology, which is applied in the fields of permeability/surface area analysis, suspension and porous material analysis, measuring devices, etc. The chemical reaction response is fast, the operation is simple and convenient, and the effect of sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

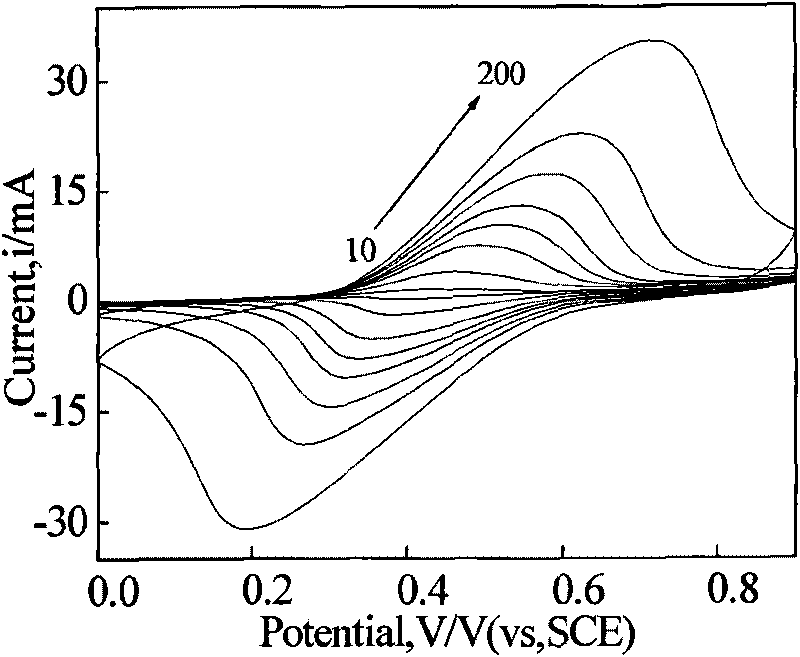

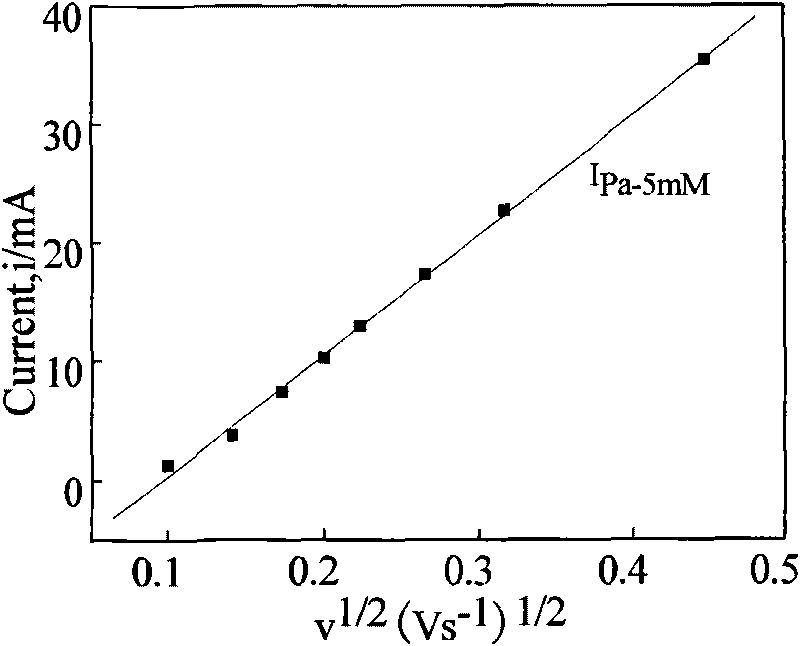

[0032] A three-dimensional porous nickel foam matrix with a length, width and thickness of 1 cm, 1 cm and 0.12 cm was used as the working electrode, and at 5 mmol L -1 K 3 Fe(CN) 6 solution (which contains 0.5mol·L -1 Na 2 SO 4 as a supporting electrolyte) to measure the cyclic voltammetry curves at different scan speeds. Scan speeds are 10, 20, 30, 40, 50, 70, 100 and 200mV·s -1 . The peak current increases with the increase of the scanning speed, and the square root of the peak current and the scanning speed shows a good linear relationship, according to the Randles-Sevick formula into [Fe(CN) 6 ] 3- The concentration c(5m mol·L -1 ) and its diffusion coefficient D(6.2×10 -6 cm 2 ·s -1 ), by the slope B of the line (101.032×10 -3 ) Calculate the electrochemical reaction active area A of the membrane electrode to be 30.168cm 2 .

[0033] Electrodeposition method was used to deposit NiHCF thin film on the nickel foam electrode, and the three-dimensional porous me...

Embodiment 2

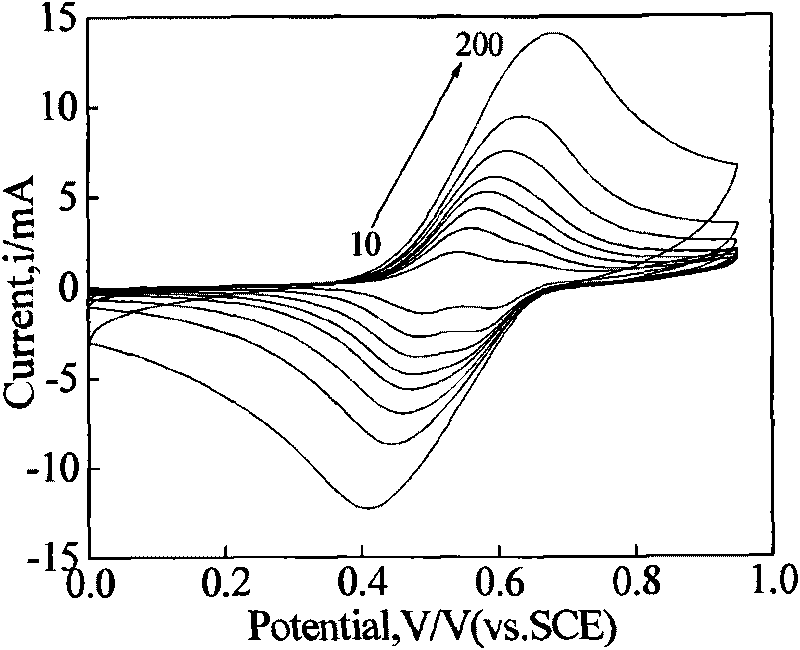

[0035] 18 graphite cores with a diameter of 2mm were divided into three rows and assembled into a multi-row graphite core matrix as a working electrode. -1 K 3 Fe(CN) 6 solution (which contains 0.5mol·L -1 Na 2 SO 4 as a supporting electrolyte) to measure the cyclic voltammetry curves at different scan speeds. Scan speeds are 10, 20, 30, 40, 50, 70, 100 and 200mV·s -1 . The peak current increases with the increase of the scanning speed, and the square root of the peak current and the scanning speed shows a good linear relationship, according to the Randles-Sevick formula into [Fe(CN) 6 ] 3- The concentration c(5m mol·L -1 ) and its diffusion coefficient D(6.2×10 -6 cm 2 ·s -1 ), by the slope B of the line (57.421×10 -3 ) Calculate the electrochemical reaction area A of the electrode as 42.296cm 2 , and the theoretical surface area of the graphite matrix is 50.87cm 2 very close.

[0036] Electrodeposition method was used to deposit NiHCF thin film on this mul...

Embodiment 3

[0039] Graphite particles with a particle size of 50-300 μm are added to an appropriate amount of polytetrafluoroethylene and ethanol, thoroughly stirred, and then coated layer by layer on a nickel mesh with a length × width of 1 cm × 1 cm. After drying, it is compressed into a three-dimensional porous conductive material. substrate; then the three-dimensional porous NiHCF membrane electrode is prepared by chemical deposition method. at 1mol L -1 KNO 3 The cyclic voltammetry curves at different scan speeds were measured in the solution. Scan speeds are 10, 20, 30, 40, 50, 70, 100 and 200mV·s -1 . The peak current increases with the increase of the scanning speed, and the square root of the peak current and the scanning speed shows a good linear relationship, and the electrochemical reaction active area A of the membrane electrode is calculated from the slope of the straight line ac 0.32cm 2 .

[0040] The porous graphite-based NiHCF membrane electrode was used as the wor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com