A kind of molecularly imprinted amphiphilic chitosan derivative lb membrane modified electrode and its construction method and application

A chitosan derivative and molecular imprinting technology is applied in the analysis of materials, material electrochemical variables, material analysis by electromagnetic means, etc., to achieve the effects of controllable film thickness, fast electrochemical response speed, and high recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

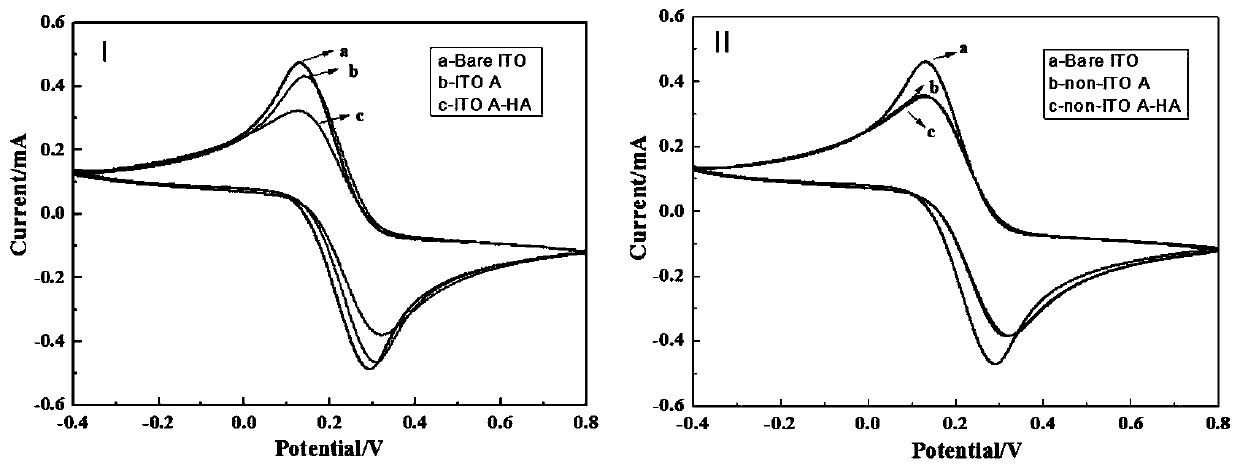

Method used

Image

Examples

Embodiment 1

[0045] Synthesis of Amphiphilic Cholesterol-Chitosan Carbonate. The steps are as follows: first in the reaction vessel, get 5.49 g cholesterol chloroformate and dissolve in N, N - In dimethylformamide, in the presence of 2.4 g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride with stirring, react for 5 h (50°C) to obtain activated cholesterol chloride Formate solution; then add 1.0 g chitosan and methanesulfonic acid in another container, stir until chitosan is completely dissolved, under nitrogen protection, add the activated cholesterol chloroformate solution obtained in the above steps dropwise, React at 50°C for 60 h. The product mixed system is precipitated, centrifuged, washed and freeze-dried to obtain cholesterol chitosan carbonate solid. The chemical structure of the product was confirmed by infrared spectrum and carbon nuclear magnetic spectrum.

Embodiment 2

[0047] (1) Preparation of Amphiphilic Cholesterol-Chitosan Carbonate and Histamine Solution

[0048] The cholesterol-chitosan carbonate solid prepared in Example 1 was formulated into a chloroform solution of cholesterol-chitosan carbonate 1.00 mg / mL for subsequent use; histamine was dissolved in ultrapure water to prepare a concentration of 1.0 mg / mL Amine solution, stored under low temperature conditions, for later use;

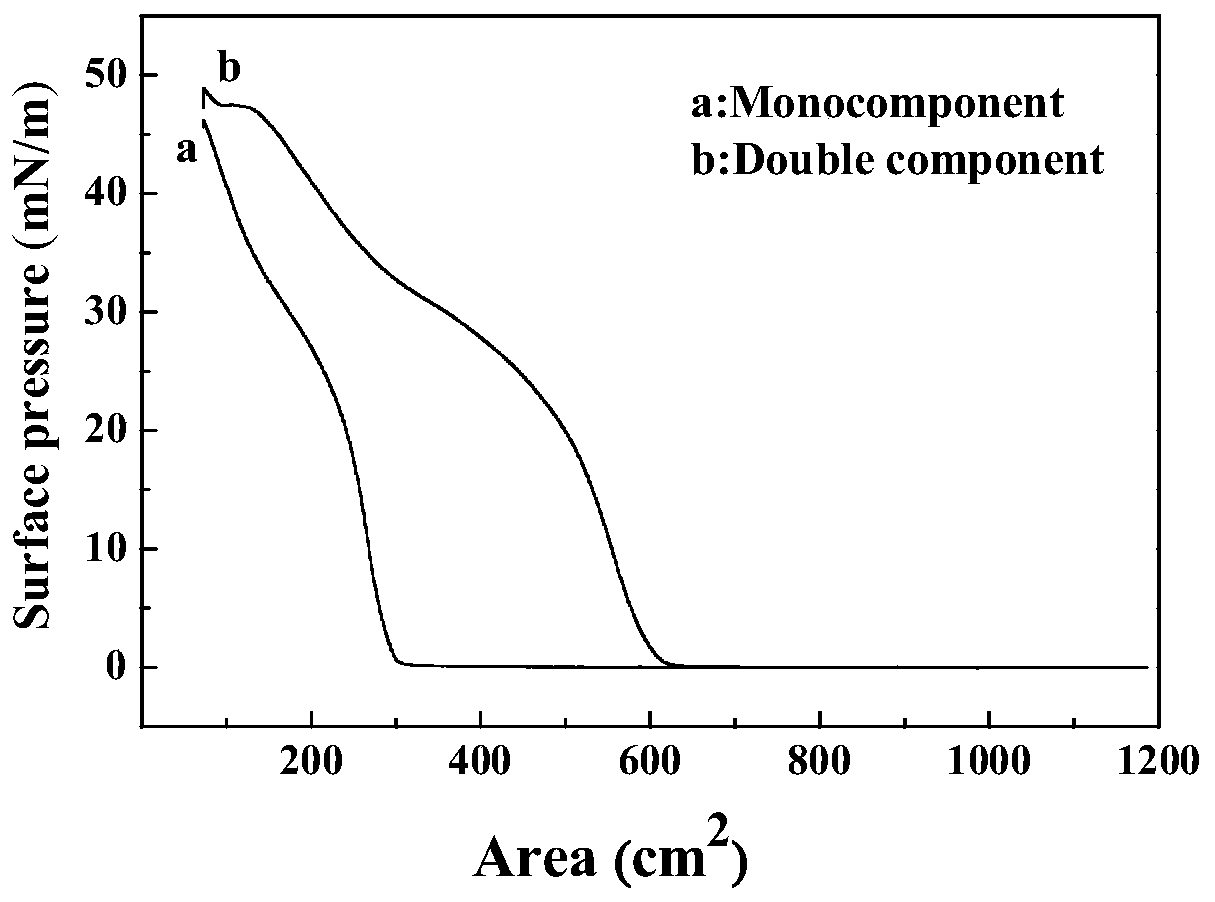

[0049] (2) Formation of Langmuir film of cholesterol-chitosan carbonate / histamine mixed component

[0050] After completing the preliminary work according to the requirements of the operation method of the Langmuir tank, add ultrapure water (resistivity ≥

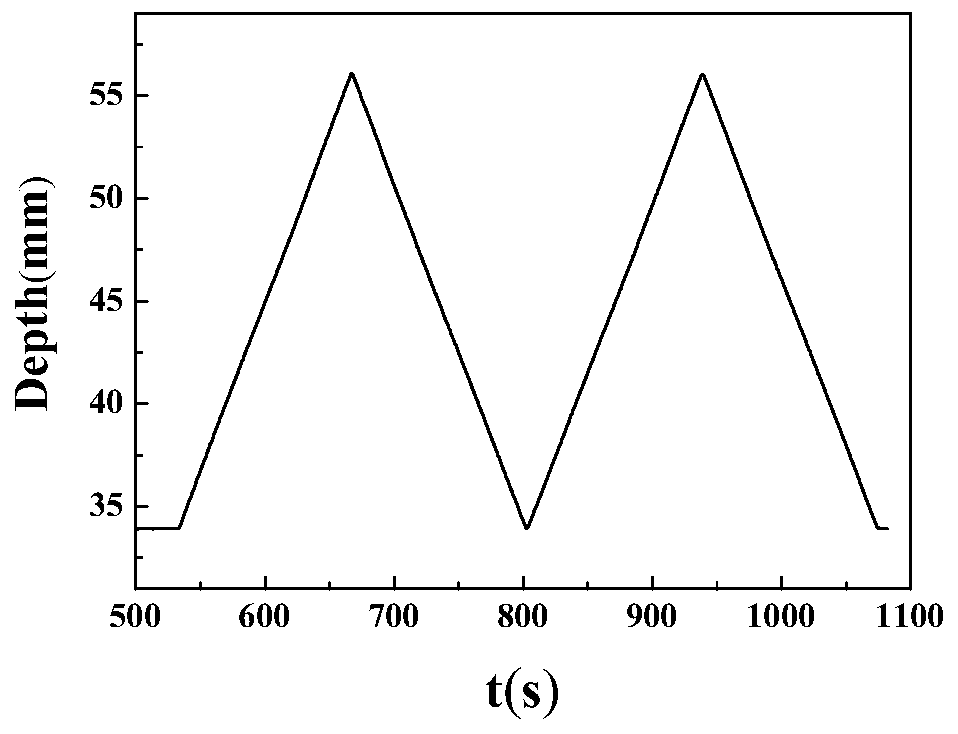

[0051] 18.25 Ω m) as a subphase, add 100 μL of histamine aqueous solution with a concentration of 0.2 mg / mL [diluted from the histamine aqueous solution prepared in step (1) of Example 2] dropwise with a micro-injector, and mix well Then use a microsampler to pipette 25 μL of the cholesterol-chitosan c...

Embodiment 3

[0053] Formation of Langmuir films of cholesterol-chitosan carbonate / histamine mixture components. After completing the preliminary work according to the requirements of the Langmuir tank operation method, add ultrapure water (resistivity ≥ 18.25 Ω m) into the tank as a subphase, and add 100 μL of histamine with a concentration of 0.2 mg / mL dropwise with a micro-injector Aqueous solution [formed by diluting the histamine aqueous solution prepared in step (1) of Example 2], after mixing evenly, pipette 50 μL of cholesterol-chitosan carbonate prepared in step (1) of Example 2 with a micro-sampler Chloroform solution, slowly added dropwise to the surface of the subphase water, making it spread on the water surface. After the chloroform is completely volatilized, the pressure sensor is reset to zero, and the sliding speed is fixed at 50 cm 2 / min, start to compress the sliding barriers A and B, and obtain a Langmuir film (monolayer) of cholesterol-chitosan carbonate / histamine mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com