Ultra-high sensitive magneto-resistance film material and preparation method thereof

A technology of thin film materials and magnetoresistance, which is applied in the fields of magnetic field controlled resistors, the application of magnetic films to substrates, and the coating process of metal materials. Index and other issues, to achieve the effect of obvious magnetic field sensitivity, convenient production, and improved spin electron scattering path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Magnetic thin films were prepared in a magnetron sputtering apparatus. Firstly, the glass substrate is ultrasonically cleaned with organic chemical solvent and deionized water, and then placed on the sample base of the sputtering chamber. The substrate is cooled with circulating water, and a magnetic field of 150 Oe is applied parallel to the direction of the substrate. Sputtering chamber background vacuum 3×10 -5 Pa, Ta ( ) / MgO( ) / Ni 81 Fe 19 ( ) / MgO( ) / Ta( ). Then the thin film material is subjected to vacuum magnetic field heat treatment, and the background vacuum degree of the annealing furnace is 8×10 -5 Pa, the annealing temperature is 400°C, the annealing time is 0.5 hour, and the annealing field is 800Oe, and the film is prepared.

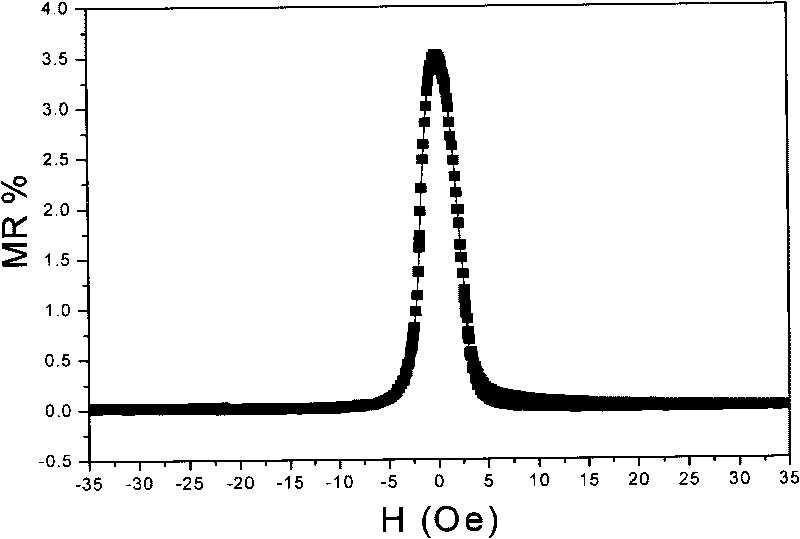

[0019] figure 1 It is the magnetoresistance output curve of the film material measured by the conventional four-probe method, and its magnetic field sensitivity is up to 2.0% Oe, which is better than that of literatur...

Embodiment 2

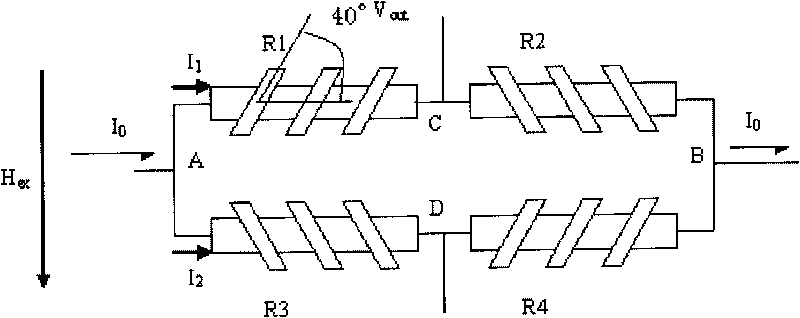

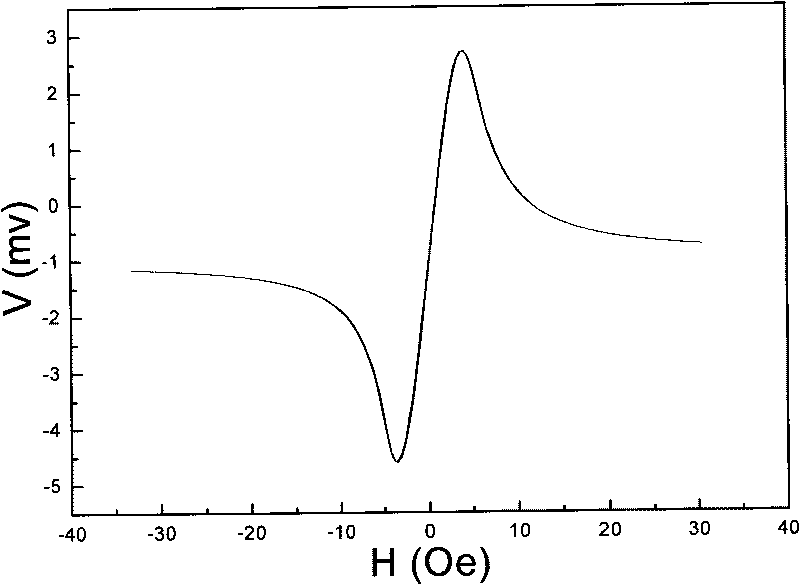

[0021] Magnetic thin films were prepared in a magnetron sputtering apparatus. Firstly, the single crystal Si(001) substrate is ultrasonically cleaned with organic chemical solvent and deionized water, and then placed on the sample base of the sputtering chamber. The substrate is cooled with circulating water, and a magnetic field of 250 Oe is applied parallel to the direction of the substrate. Sputtering chamber background vacuum 4×10 -5Pa, NiFeCr ( ) / (MgO ) / Ni 80 Fe 20 ( ) / (MgO ) / Au( ). Then the thin film material is subjected to vacuum magnetic field heat treatment, and the background vacuum degree of the annealing furnace is 4×10 -5 Pa, the annealing temperature is 500°C, the annealing time is 2 hours, and the annealing field is 900Oe, and the film is prepared. The magnetoresistance output curve of the thin film material measured by the conventional four-probe method shows that the maximum magnetic field sensitivity is 2.3% / Oe. Then, the thin film material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com