Myceliophthora thermophilia strain and application thereof in aspect of producing keratinase

A technology of Myceliophthora thermophila and keratinase is applied in the field of Myceliophthora thermophila strains to achieve the effects of reducing the probability of contamination, growing rapidly and increasing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

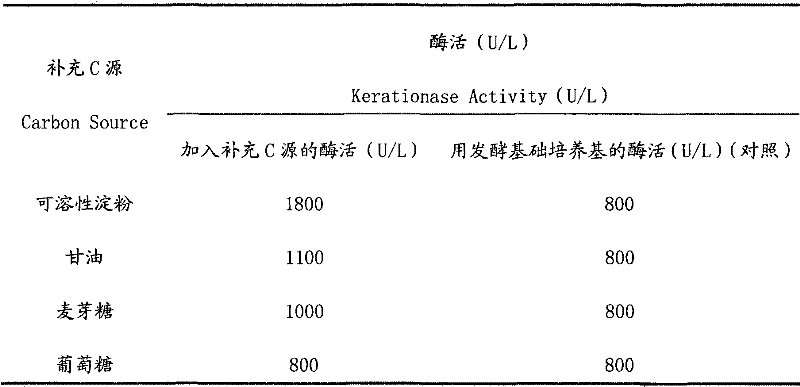

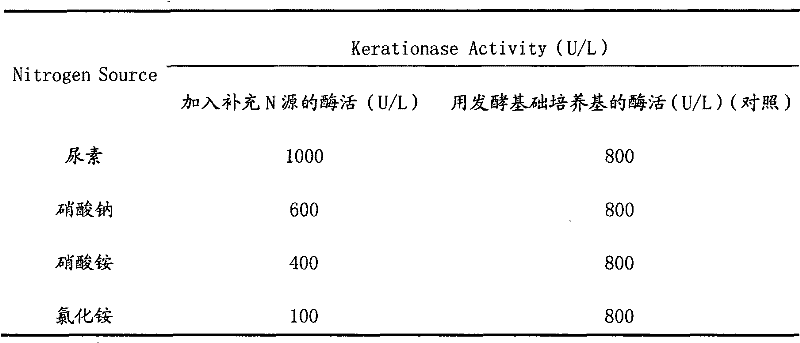

Examples

Embodiment 1

[0014] (1) Source of material

[0015] Soil samples collected from Pingwu, Sichuan.

[0016] Martin's Medium: KH 2 PO 4 1g, MgSO 4 .7H 2 O 0.5g, peptone 5g, glucose 10g, agar 18g, Bengal red 1 / 300mL. Sterilization conditions: 121°C, 30min. Wait until the temperature is cooled to about 40°C before use, add penicillin 20 / mg, streptomycin 40μg / mg.

[0017] PDA medium: cut 200g of potatoes into pieces, add about 500mL of water, boil for 30min, filter, add 20g of glucose, 20g of agar, make up 1000mL of water, and the pH is natural. Sterilization conditions: 121°C, 30min.

[0018] (2) Isolation and purification of bacterial strains

[0019] Weigh 2g of soil sample into a conical flask filled with 20mL of sterile water and glass beads, shake for about 10min, so that the soil sample is evenly dispersed in the diluent to become a soil suspension.

[0020] Pipette 1mL of soil suspension into 9mL of sterile water, and dilute in turn by 10 times, usually at 10 -1 ~10 -3 .

[...

Embodiment 2

[0027] The method for Myceliophthora thermophila GZUIFR-H94.1 strain producing keratinase, comprises the following steps:

[0028] (1) culture medium

[0029] Shake flask fermentation medium: chicken feather powder 20.10g, urea 0.98g, NaCl 5g, K 2 HPO 4 6g, KH 2 PO 4 1g, water 1000m, initial pH is 7.9.

[0030] (2) Liquid fermentation culture

[0031] Bacterial strain of the present invention is inoculated in the petri dish containing solid PDA medium, cultivated for 3 days at 38°C, punched out with a hole puncher with a diameter of 7mm, and then inoculated the mycelium block into 250mL of 50mL re-screened liquid medium. In the triangular flasks, each bottle was connected with 3 wells of mycelium blocks, and each group was replicated 3 times, placed in a shaker at 38°C, kept at 140rpm for static culture, and the enzyme activity was measured.

[0032] (3) Preparation of crude enzyme solution

[0033] Preparation of spore liquid: take the strains stored in the refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com