Method for preventing cell-carrying sodium alginate microcapsule from shrinking

A technology of sodium alginate and calcium alginate, which is applied in the direction of microcapsules, capsule delivery, and pharmaceutical formulations, and can solve problems affecting the molecular interception performance of microcapsule composite membranes, affecting biocompatibility, and shrinkage of microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation process of sodium alginate microcapsules of the above-mentioned cells is often reported in the literature (Yang Xiaoming, Bi Haosheng, Yang Maoyuan, etc., research on the in vitro culture of microencapsulated human chromaffin cells [J]. Chinese Journal of Anesthesiology, 2001; 21 (7) : 410-413. Xue Yilong (CN1345234, microencapsulated bovine adrenal medulla chromaffin cell drug for treating pain), does not belong to the content of the present invention.

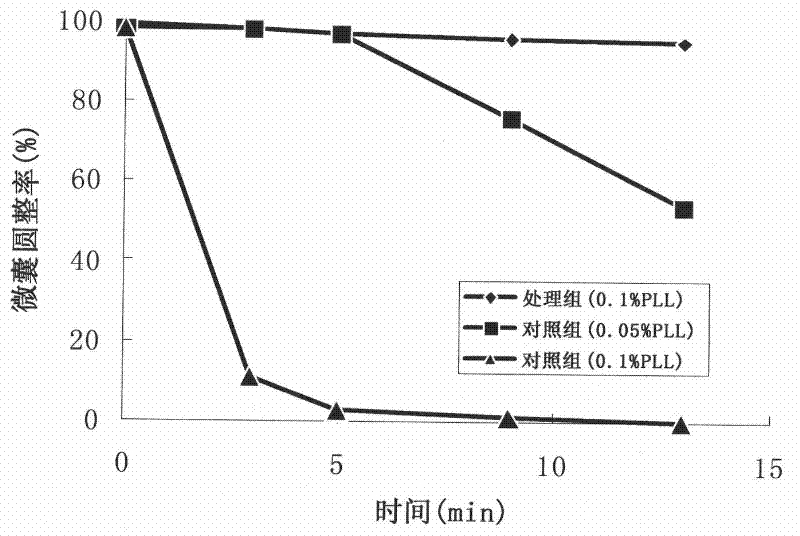

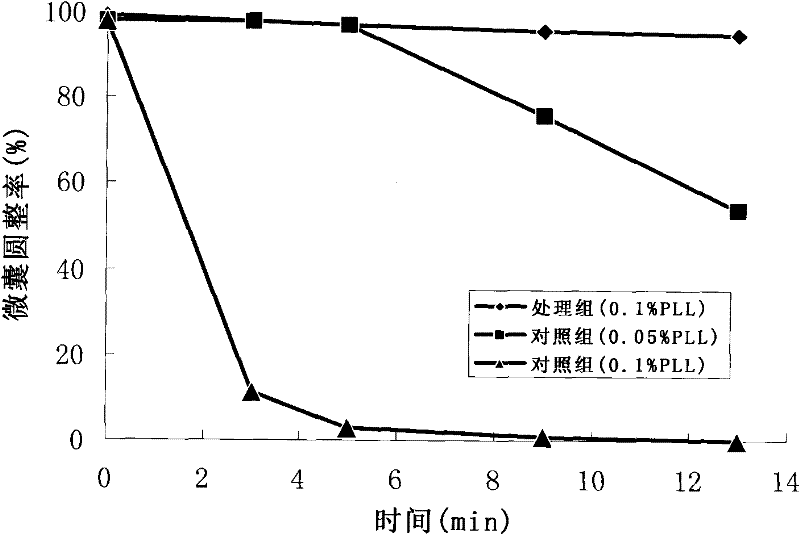

[0027] The present invention provides a new method for preventing the shrinkage of sodium alginate microcapsules, that is, after the sodium alginate solution encapsulates cells and forms calcium alginate microspheres (after the second step), that is, after coating polylysine or before chitosan (before step 3), place the calcium alginate microspheres in the polyol solution for processing, let stand, remove the lower layer of calcium alginate microspheres to precipitate, and further react with polylysine o...

Embodiment 1

[0028] Example 1: Preparation of APA microcapsules coated with bovine adrenal medulla chromaffin cells BCC

[0029] (1) The total number of cells is 1×10 61 bovine adrenal medulla chromaffin cells (BCC) were mixed with 1 ml of 1.5% sodium alginate solution, and made into a suspension by stirring. .

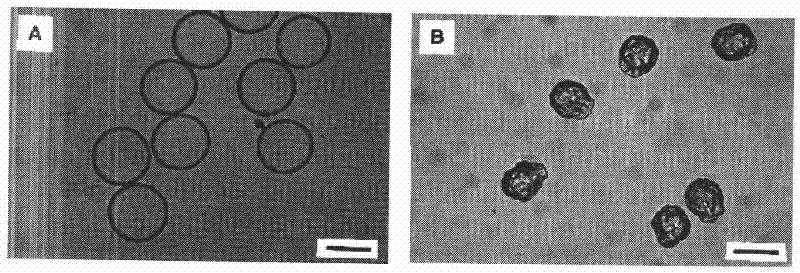

[0030] (2) Use a high-voltage electrostatic droplet generator to spray the suspension into 50ml of calcium chloride solution with a concentration of 100mmol / L, and after standing for 10min, obtain calcium alginate with a diameter in the range of 180-500μm The microspheres were precipitated, and the supernatant was removed after the precipitation was complete.

[0031] (3) Then add the calcium alginate microspheres into 50ml of mannitol solution with a concentration of 0.3mol / L, place it at room temperature for 5-10min, and remove the supernatant after the precipitation is complete.

[0032] (4) Then put the precipitate in 0.05% polylysine solution, mix well, place at room tempe...

Embodiment 2

[0036] Example 2: Preparation of APA microcapsules coated with rat pancreatic islet tissue. The steps are the same as in Example 1, but the difference from Example 1 is that the polyol solution used in step (3) is in a physiological isotonic sorbitol solution, placed at room temperature for 20 min, and the supernatant is removed after the precipitation is complete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com