Method for preparing thermocompressed polycrystalline magnesium fluoride powder

A crystalline magnesium fluoride and powder technology, which is applied in the field of hot-pressed polycrystalline magnesium fluoride powder preparation, can solve the problems of very high quality requirements of basic magnesium carbonate, environmental pollution, mother liquor not being closed-circuited, etc. Significant environmental benefits, significant economic benefits, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

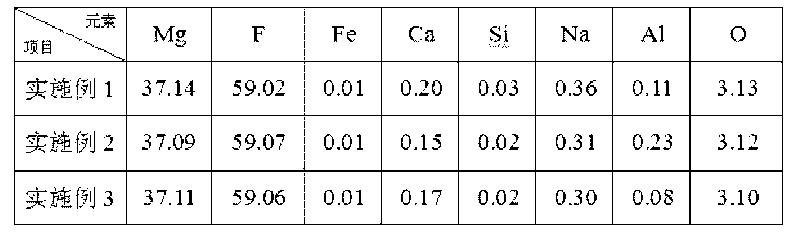

Embodiment 1

[0016] The preparation method of hot-pressed polycrystalline magnesium fluoride powder comprises the following steps:

[0017] (1) Purify raw materials

[0018] Weigh 150g of industrial grade MgSO 4 ·7H 2 O is mixed with the magnesium sulfate solution that mass percent concentration is 35%, adjusts the pH value to 9, then adds 10g weight percent concentration and is 40% hydrogen peroxide, stirs 0.5 hour, obtains the purified magnesium sulfate solution through filtration; Take 64g industrial Grade sodium carbonate is mixed with the sodium carbonate solution that mass percent concentration is 10%, adds the magnesium sulfate solution of 15g purification wherein, stirs 2 hours, goes out heavy metal impurity wherein by reaction co-precipitation, obtains the sodium carbonate solution of purification through filtration;

[0019] (2) prepare basic magnesium carbonate

[0020] Heat the purified magnesium sulfate solution and the purified sodium carbonate solution to 50°C respectivel...

Embodiment 2

[0024] The preparation method of hot-pressed polycrystalline magnesium fluoride powder comprises the following steps:

[0025] (1) Purify raw materials

[0026] Weigh 200g of industrial grade MgSO 4 ·7H 2 O is mixed with the magnesium sulfate solution that mass percent concentration is 10%, adjusts pH value to 8, then adds 20g weight percent concentration and is 55% hydrogen peroxide, stirs 1 hour, obtains purified magnesium sulfate solution through filtration; Weigh 85g industrial Grade sodium carbonate is mixed with the sodium carbonate solution that mass percent concentration is 30%, adds the magnesium sulfate solution of 6g purification wherein, stirs 1 hour, goes out heavy metal impurity wherein by reaction coprecipitation, obtains the sodium carbonate solution of purification through filtration;

[0027] (2) prepare basic magnesium carbonate

[0028] Heat the purified magnesium sulfate solution and the purified sodium carbonate solution to 70°C respectively, then slow...

Embodiment 3

[0032] The preparation method of hot-pressed polycrystalline magnesium fluoride powder comprises the following steps:

[0033] (1) Purify raw materials

[0034] Weigh 246g of industrial grade MgSO 4 ·7H 2 O is mixed with the magnesium sulfate solution that weight percent concentration is 20%, adjusts the pH value to 8, then adds 60g weight percent concentration and is 30% hydrogen peroxide, stirs 1 hour, obtains purified magnesium sulfate solution through filtration; Weigh 100g industrial Grade sodium carbonate is mixed with the sodium carbonate solution that weight percent concentration is 5%, adds the magnesium sulfate solution of 20g purification wherein, stirs 2 hours, goes out wherein heavy metal impurity by reaction coprecipitation, obtains the sodium carbonate solution of purification through filtration;

[0035] (2) prepare basic magnesium carbonate

[0036] Heat the purified magnesium sulfate solution and the purified sodium carbonate solution to 30°C respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com