Process for processing saccharin sodium wastewater

A treatment process, sodium saccharin technology, applied in the field of sodium saccharin wastewater treatment process, can solve the problems of unbearable high concentration impact load, high cost, high construction investment of sewage treatment plants, etc., to improve stability and treatment effect, reduce Reaction volume and effect of shortening start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

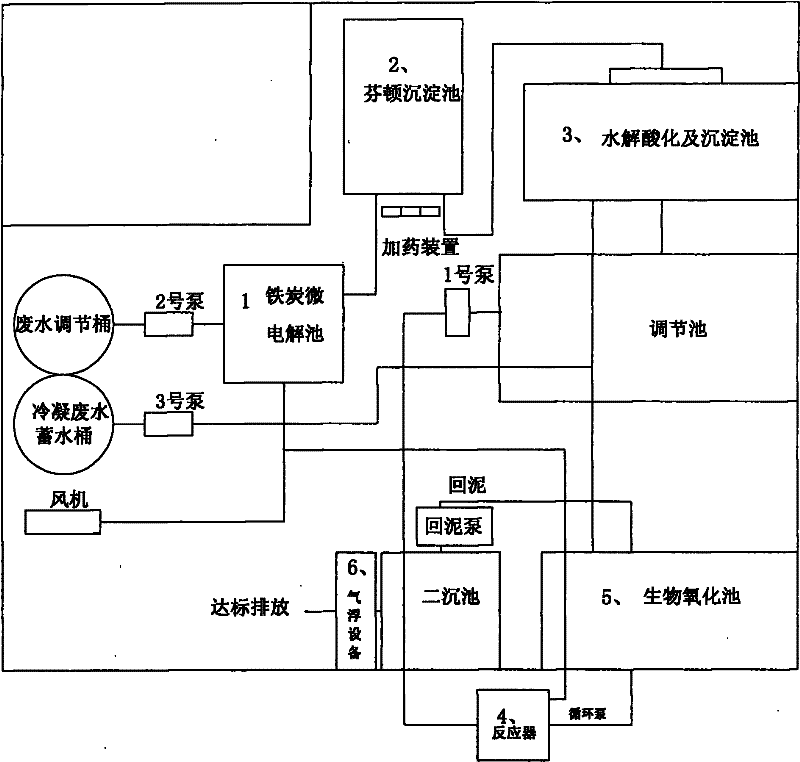

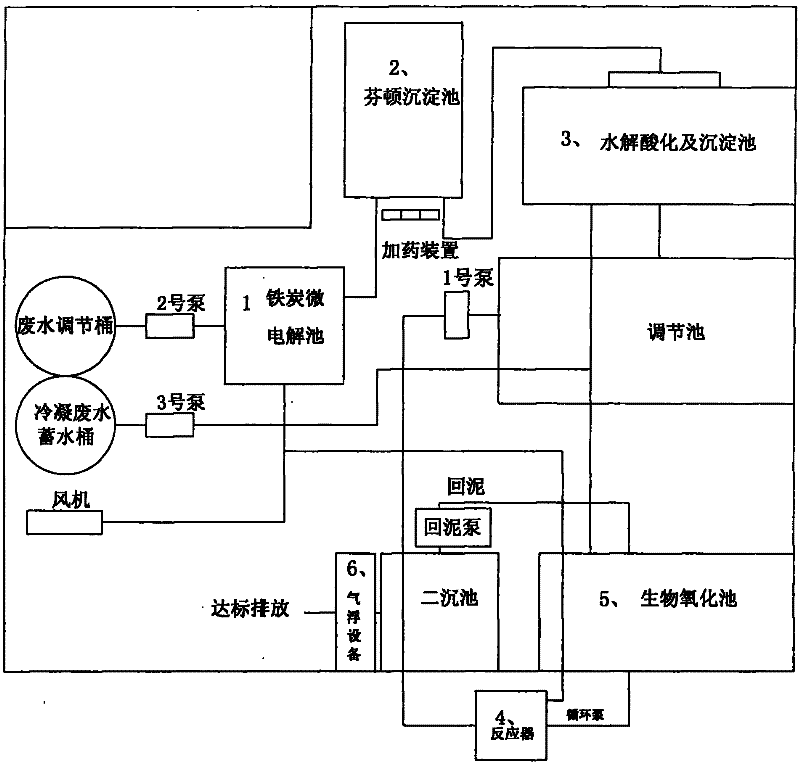

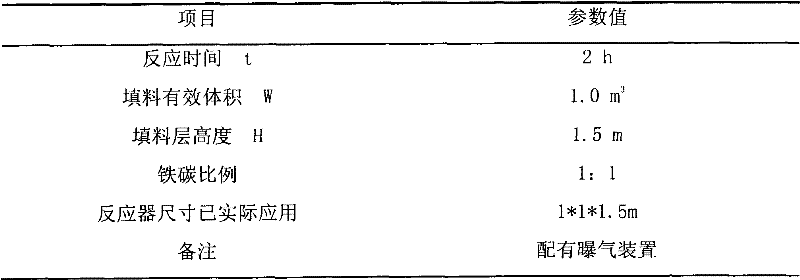

[0024] A treatment process for sodium saccharin waste water, the steps are:

[0025] (1) The waste water is pumped into the iron-carbon micro-electrolytic cell 1 through the No. 2 lift pump from the waste water regulating tank for pretreatment.

[0026] Iron-carbon micro-electrolysis method is a good process for treating wastewater by using the reaction principle of Fe / C primary battery, also known as internal electrolysis method, iron filings filtration method, etc. Complexation, electrodeposition and co-precipitation are integrated into one. As a pretreatment technology before biochemical treatment, iron-carbon micro-electrolysis technology can not only greatly reduce the concentration of organic matter, but also remove or reduce the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com