Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of low pore volume of silicon-based cracking catalysts, improve cracking activity, reduce pollution, and achieve good coke selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

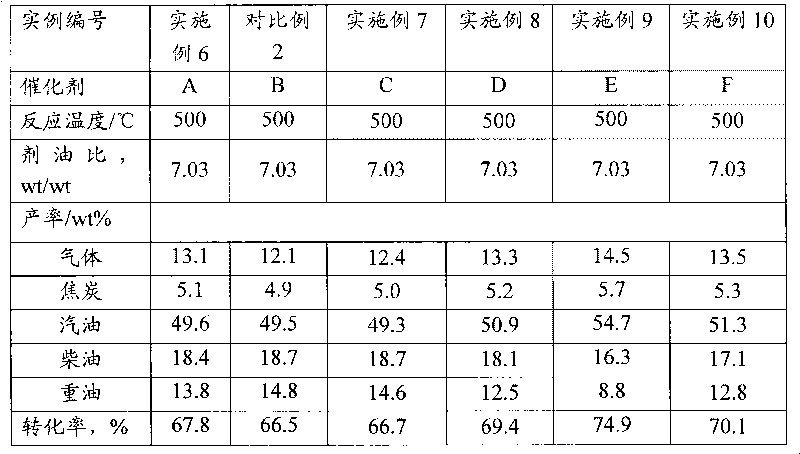

Examples

preparation example Construction

[0021] In the preparation method provided by the present invention, the alkali silica sol obtained by contacting the water glass with an acid can exist stably at a higher temperature, and has better stability in the temperature range of 0-60°C, thus The contacting can be performed at room temperature. Preferably, the temperature of the silica sol obtained by contacting water glass with acid is 0-45°C.

[0022] In the preparation method provided by the invention, described in the step (1), the water glass is contacted with the inorganic acid, which can be a batch mode or a continuous mode. During batch mode production, acid is preferably added to the water glass solution.

[0023] In the method provided by the invention, the consumption of water glass in step (1) should make the content of silicon binding agent in the prepared catalyzer meet the requirements, take the weight of the prepared catalyzer as a basis, take SiO 2 The content of the silicon binder in the prepared cat...

Embodiment 1

[0032] Under the room temperature of 34 ℃, 7.5kg sodium water glass (produced by Sinopec Catalyst Qilu Branch, SiO 2 Content 20% by weight, modulus 3.2) mixes with 10.2kg decationized water, then under stirring, adding therein concentration is 1.14kg of sulfuric acid solution of 25% by weight, obtains SiO 2 Silica sol with a concentration of 8% by weight and a pH value of 10.81. A little flocculation occurred in the silica sol after standing for 24 hours, but no gel was formed.

[0033] Add 3.2 kg of kaolin (produced by China Kaolin Company, solid content: 84% by weight) to 3.8 kg of decationized water, and beat to obtain a kaolin slurry.

[0034] Add 2.1 kg of USY molecular sieve (produced by Catalyst Qilu Branch Company, solid content 84.9%) into 2.5 kg of decationized water, and beat to obtain molecular sieve slurry.

[0035] The above-mentioned silica sol, kaolin slurry, and molecular sieve slurry are mixed and stirred to obtain a sol-state catalyst slurry with a pH valu...

Embodiment 2

[0049] Under 38 ℃, 7.8kg sodium silicate (produced by Catalyst Qilu Branch, containing SiO 2 Concentration 15%, modulus 2.8) mixes with 10.0kg decationized water, then adds 1.71kg of 15% by weight sulfuric acid thereto under stirring, obtains SiO 2 Silica sol with a concentration of 6% by weight and a pH value of 10.3.

[0050] 4.2 kg of montmorillonite (manufactured by Nanhua Hongshan Bentonite Co., Ltd., with a solid content of 78.6% by weight) was added to 4.1 kg of decationized water, and beaten to obtain a montmorillonite slurry.

[0051] Add 1.63 kg of DASY molecular sieve (manufactured by Catalyst Qilu Branch Company, solid content 91.8%) into 2.65 kg of decationized water, and beat to obtain molecular sieve slurry.

[0052] Mix the above-mentioned silica sol, montmorillonite slurry, and molecular sieve slurry, and stir to obtain a sol-state catalyst slurry with a pH value of 10.2. Spray-dry the slurry to obtain microspherical catalyst particles, and then spray the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com