Preparation method of radio frequency glow discharge inductively coupled plasmas of nano powder material

A radio frequency glow discharge and radio frequency plasma technology, applied in the preparation of oxide/hydroxide, etc., can solve the problems of coarse powder particle size, chemical group contamination on the powder surface, and uneven distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

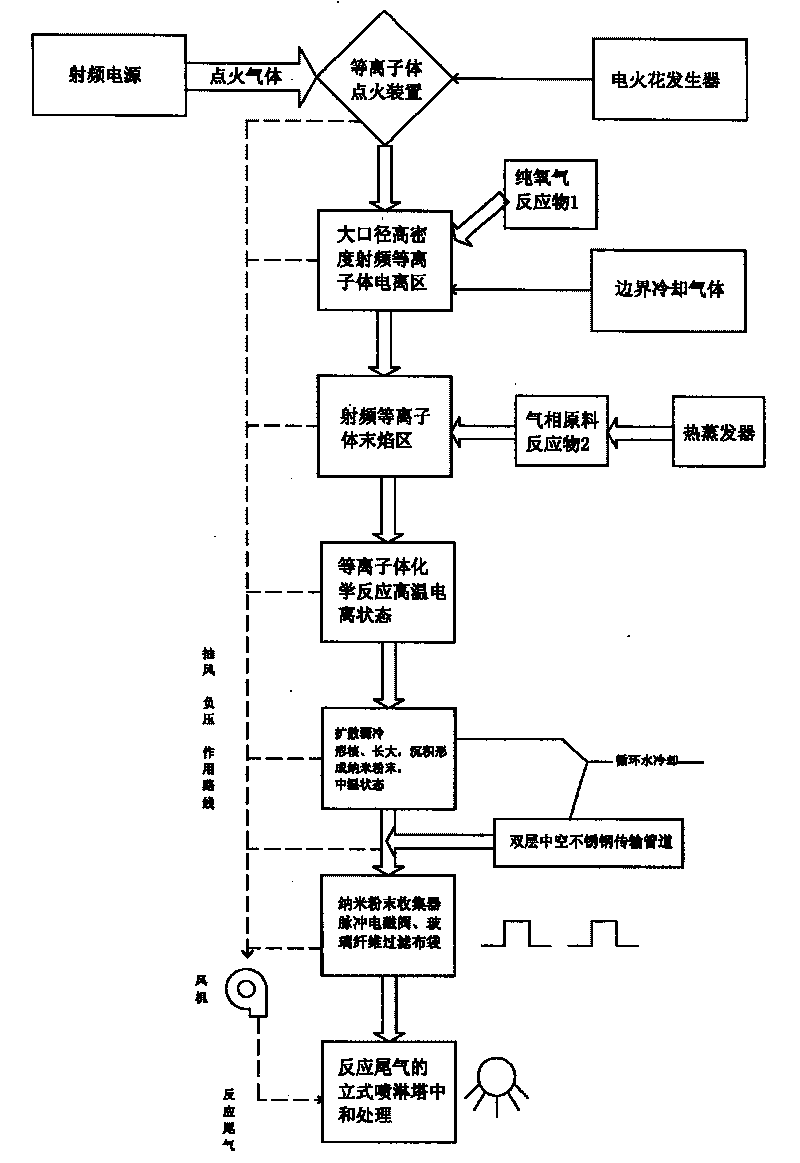

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

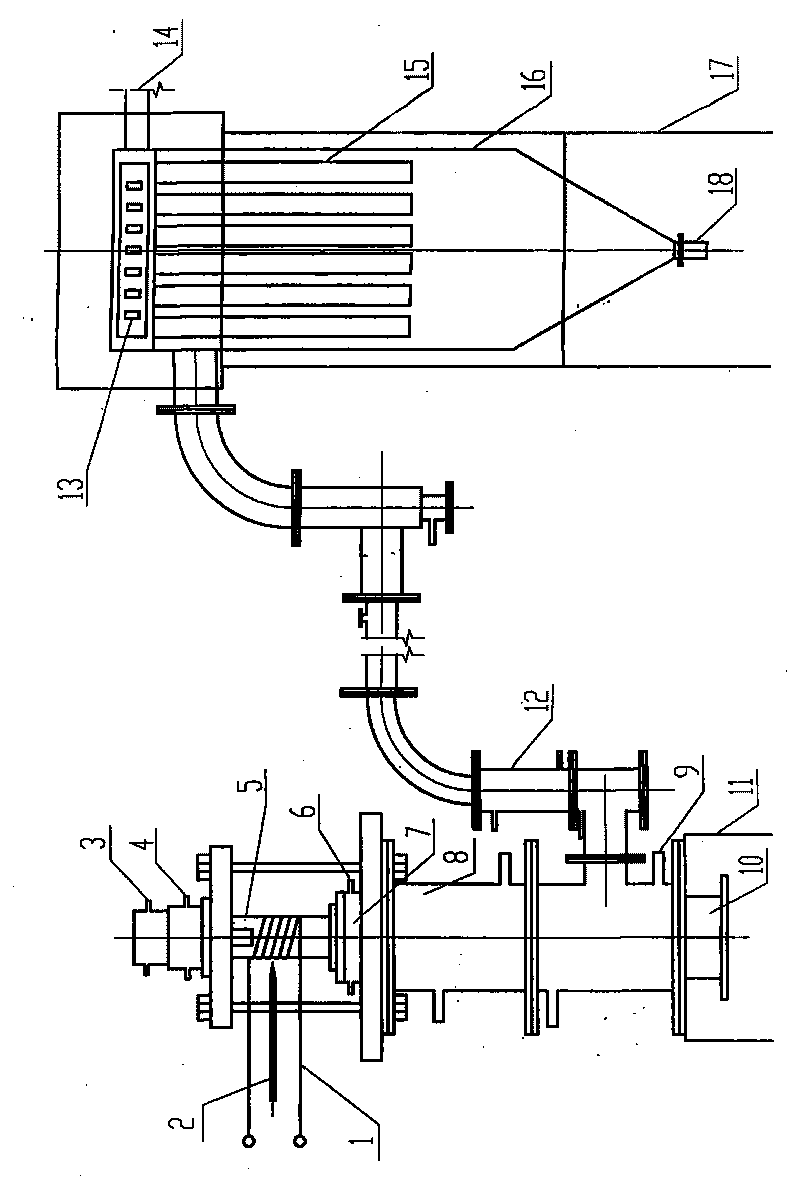

[0038] Step 1: Connect the oxygen, that is, the edge oxygen for cooling, and the ignition gas argon, the pressure of oxygen is 0.3-0.4MPa, and the pressure of argon is 0.2MPa. Turn on the exhaust fan, and the exhaust pressure is 500-1500Pa. Connect the circulating water to start cooling the electronic tube, radio frequency power supply and induction coil (antenna) 1, please refer to figure 2 , water pressure 0.2 ~ 0.5MPa. Turn on the power supply of the reaction raw material heater (evaporator), start heating the liquid-phase reaction raw material to vaporized gaseous state, or the powder raw material conveying device is ready. Turn on the power supply of the electronic tube to preheat for 20 to 40 minutes.

[0039] Step 2: Connect the high voltage power supply, adjust the spark generator 2, see figure 2 , generate electric sparks, and ionize the small quartz tube 5 (attached figure 2 ) in the argon, forming an argon plasma flame.

[0040] Step 3: Slowly reduce the flo...

Embodiment 2

[0045] Example 2 - Preparation of nm-SiO 2 Key process parameters of powder materials:

[0046] Preparation of non-metallic oxide nm-SiO by RF glow discharge inductively coupled plasma technique 2 powder material

[0047] RF plasma device FD-934S, side-heated electron tube, forced cooling by circulating water.

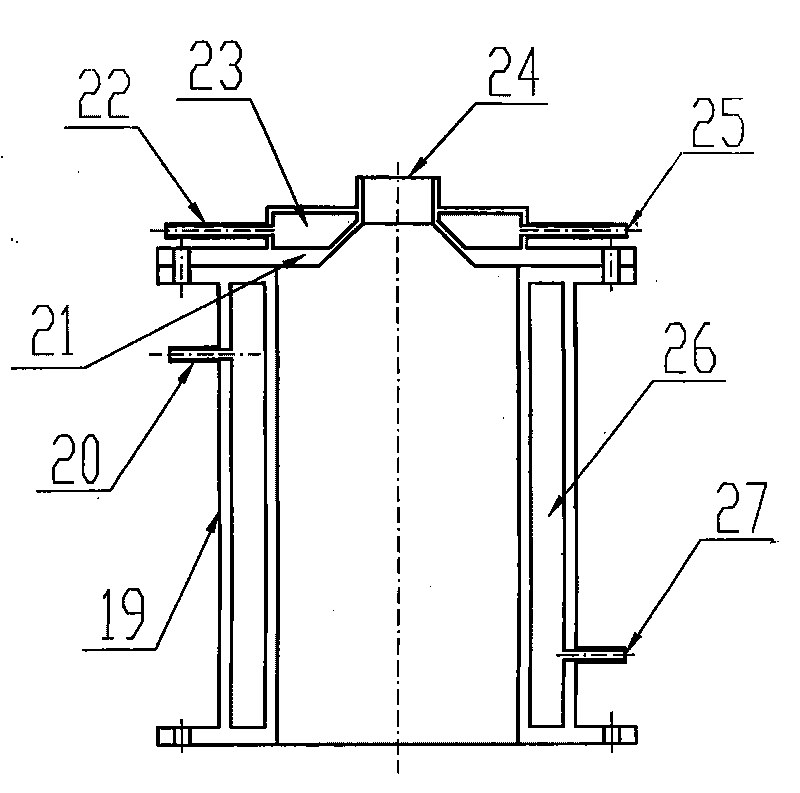

[0048] The inner diameter of the large quartz tube is 70mm, the inner diameter of the small quartz tube is 50mm, the wall thickness is 3.5mm, the diameter of the glow discharge coil (antenna) is 120mm, and the diameter of the copper core (hollow, cooled by water) is 12mm. The diameter of the first-stage diffuser in the two-stage diffuser is 80 mm, the taper is 45 degrees, and the inner diameter of the second-stage diffuser is 250 mm.

[0049] The operating conditions of the preparation device are as follows:

[0050] 1. Ignition gas, the volume flow rate of argon gas is 3m 3 / h;

[0051] 2. Working gas, oxygen volume flow rate is 8m 3 / h;

[0052] 3. Boundary c...

Embodiment 3

[0058] Example 3 - Preparation of nm-TiO 2 Key process parameters of powder materials:

[0059] Preparation of Metal Oxide nm-TiO by Radio Frequency Glow Discharge Inductively Coupled Plasma Technology 2 powder material

[0060] RF plasma device FD-934S, side-heated electron tube, forced cooling by circulating water.

[0061] The inner diameter of the large quartz tube is 70mm, the inner diameter of the small quartz tube is 50mm, the wall thickness is 3.5mm, the diameter of the glow discharge coil (antenna) is 120mm, and the diameter of the copper core (hollow, cooled by water) is 12mm. The diameter of the first-stage diffuser in the two-stage diffuser is 80 mm, the taper is 45 degrees, and the inner diameter of the second-stage diffuser is 250 mm.

[0062] The operating conditions of the preparation device are as follows:

[0063] 1. Ignition gas, the volume flow rate of argon gas is 4m 3 / h;

[0064] 2. Working gas, oxygen volume flow rate is 10m 3 / h;

[0065] 3. Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com