Physical foaming ethane-butadiene rubber composite capable of being injected and crosslinked, as well as preparation method, product and processing method thereof

A technology of rubber composition and physical foaming, applied in application, apparel, footwear, etc., can solve the problems of high toxicity of polyurethane monomer, high density of soles, high melt viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

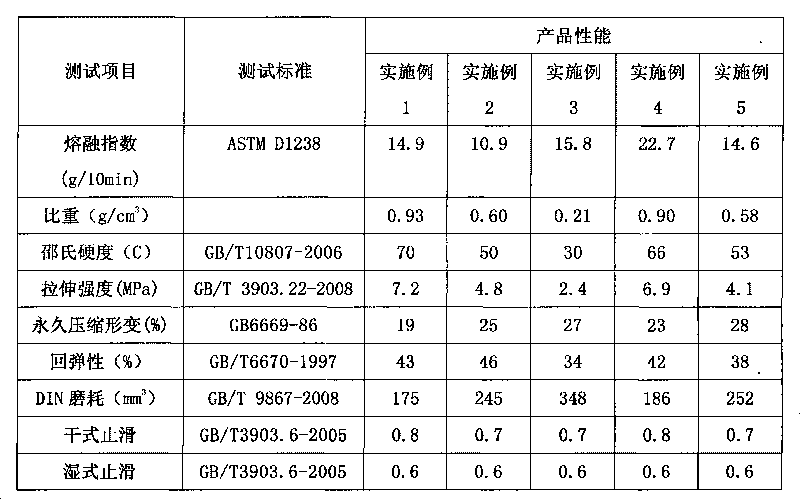

Examples

Embodiment 1

[0032] According to the following components and content (parts by mass)

[0033] Styrene-butadiene copolymer 50 parts

[0034] Butadiene rubber 10 parts

[0035] Styrene-butadiene-styrene copolymer 5 parts

[0036] Silicon dioxide 14 parts

[0037] 10 parts recycled rubber

[0038] 10 parts naphthenic oil

[0039] Dicumyl peroxide 0.4 parts

[0040] Triallyl isocyanurate 0.3 parts

[0041] Low temperature foaming microspheres 0.3 parts

[0042] First, put the styrene-butadiene copolymer, styrene-butadiene-styrene copolymer, butadiene rubber, silicon dioxide, regenerated rubber, and naphthenic oil in the internal mixer at the same time for internal mixing , mixed for 5 minutes, then added dicumyl peroxide, triallyl isocyanurate, and low-temperature foaming microspheres, mixed for 2 minutes, and the temperature of the internal mixer was 100 ° C. Mix in a mill, and pass through 10 times before the next tablet. Finally, the rubber material is extruded and granulated by an ...

Embodiment 2

[0044] According to the following components and content (parts by mass)

[0045] Styrene-butadiene copolymer 40 parts

[0046] EPDM rubber 10 parts

[0047] Ethylene-vinyl acetate copolymer 15 parts

[0048] Talcum powder 13.5 parts

[0049] Regenerated EVA powder 10 parts

[0050] Machine oil 10 parts

[0051] 0.2 parts of tert-butylcumyl peroxide

[0052] Trimethylolpropane tris(2-methacrylate) 0.3 parts

[0053] Low-temperature foaming microspheres 1 part

[0054] First, put the styrene-butadiene copolymer, ethylene-vinyl acetate copolymer, EPDM rubber, talc powder, recycled EVA powder, and mechanical oil in the internal mixer at the same time for internal mixing, and mix for 5 minutes . Then add tert-butyl cumyl peroxide, trimethylolpropane tri(2-methacrylate) ester, and low-temperature foaming microspheres, mix for 2 minutes, and the temperature of the banbury mixer is 100°C, and the rubber compound after banbury mixing is used Mix in a mill, and pass through 10...

Embodiment 3

[0056] According to the following components and content (parts by mass)

[0057] Styrene-butadiene copolymer 49 parts

[0058] 10 parts nitrile rubber

[0059] Styrene-ethylene-propylene-styrene copolymer 5 parts

[0060] Silicon dioxide 13.5 parts

[0061] 10 parts recycled rubber powder

[0062] Aromatic oil 10 parts

[0063] 0.2 parts of tert-butylcumyl peroxide

[0064] Trimethylolpropane tris(2-methacrylate) 0.3 parts

[0065] Low-temperature foaming microspheres 2 parts

[0066] First, put the styrene-ethylene-propylene-styrene copolymer and aromatic oil in the above ratio into an internal mixer for internal mixing, mix for 3 minutes, then add styrene-butadiene copolymer, nitrile rubber, dioxide Silicone, regenerated rubber powder, mix for 8 minutes, then add tert-butyl cumyl peroxide, trimethylolpropane tri(2-methacrylate) ester, low-temperature foaming microspheres, mix for 2 minutes, internal mixer temperature 100 ℃, mix the rubber materials after banburying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com