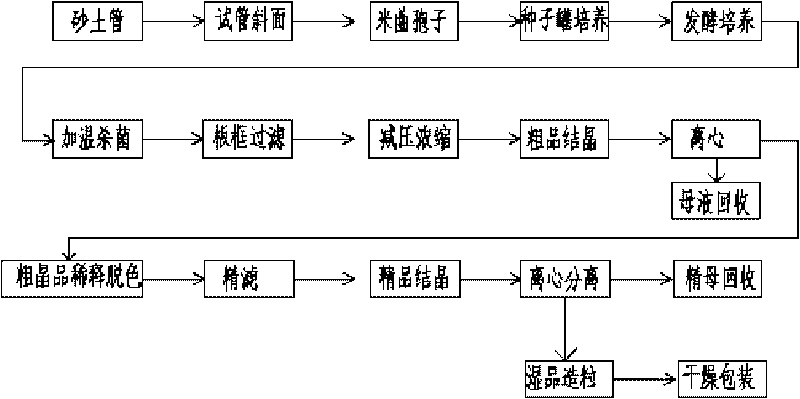

Method for producing calcium gluconate by fermenting Aspergillus niger

A technology for calcium gluconate and Aspergillus niger fermentation, which is applied in the field of calcium gluconate production, can solve the problems of impact on the purity and yield of finished products, high production labor intensity, long production cycle, etc., so as to reduce the amount of secondary water and improve labor productivity. , the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

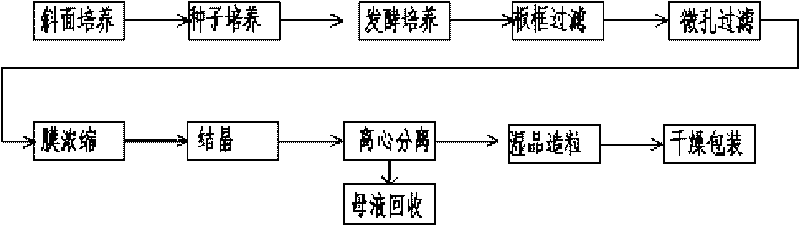

[0019] Such as image 3 Shown, the method for fermenting and producing calcium gluconate by Aspergillus niger described in this embodiment, it comprises seed culture and fermentation culture, it is characterized in that adopting Aspergillus niger TN9518 slant bacterial classification to ferment and ferment glucose liquid, glucose is converted into gluconic acid, and Calcium gluconate is generated after calcium exchange with calcium-containing compounds, and then the finished product of calcium gluconate is formed after sterilizing filtration, concentrated crystallization, separation and drying. The preferred scheme is that the calcium exchange with the calcium compound refers to the neutralization with calcium carbonate, and the chemical reaction formula is:

[0020]

[0021]

[0022] The main steps are as follows:

[0023] 1. Seed culture medium:

[0024] Elute the Aspergillus niger TN9518 slant strain with sterile water and pour it into the seed culture medium. At a ...

Embodiment 2

[0035] The method that the Aspergillus niger fermenting production calcium gluconate described in the present embodiment, main steps are as follows:

[0036] 1. Seed culture medium:

[0037] Elute the Aspergillus niger TN9518 slant strain with sterile water and pour it into the seed culture medium. At a temperature of 38°C, feed air with a gas-liquid ratio of 1m3 / m3, start stirring, and cultivate for 20 hours to obtain a seed culture solution. The pH value 6.8, seed medium composition (mass percentage concentration): glucose 7% corn steep liquor 0.5%, peptone 0.2%, calcium carbonate 5%, pH value-natural.

[0038] 2. Fermentation

[0039] Insert the seed liquid into the fermentation broth culture medium with the inoculation amount of 12% weight ratio of the fermentation broth, feed air at 38°C, the gas-liquid ratio is 1.4m3 / m3, start stirring, and cultivate for 16 hours to convert glucose into gluconic acid, medium and calcium carbonate to form calcium gluconate. The residua...

Embodiment 3

[0047] The method that the Aspergillus niger fermenting production calcium gluconate described in the present embodiment, main steps are as follows:

[0048] Seed Culture Solution:

[0049]Elute the Aspergillus niger TN9518 slant strain with sterile water and pour it into the seed culture medium. At a temperature of 32°C, feed air with a gas-liquid ratio of 0.5m3 / m3, start stirring, and cultivate for 20 hours to obtain a seed culture solution. 6.8, seed medium composition (mass percentage concentration): glucose 7% corn steep liquor 0.5%, peptone 0.2%, calcium carbonate 5%, pH value-natural.

[0050] fermentation

[0051] Insert the seed liquid into the fermentation broth culture medium with the inoculation amount of 10% by weight of the fermentation broth, feed air at 32°C, the gas-liquid ratio is 1.3m3 / m3, start stirring, and cultivate for 15 hours to convert glucose into gluconic acid, medium and calcium carbonate to form calcium gluconate. The residual sugar is ≤0.4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com