Load type sulfur-tolerant methanation catalyst and preparation method and application thereof

A technology for sulfur-resistant methanation and catalyst, which is applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. The effect of improving utilization and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

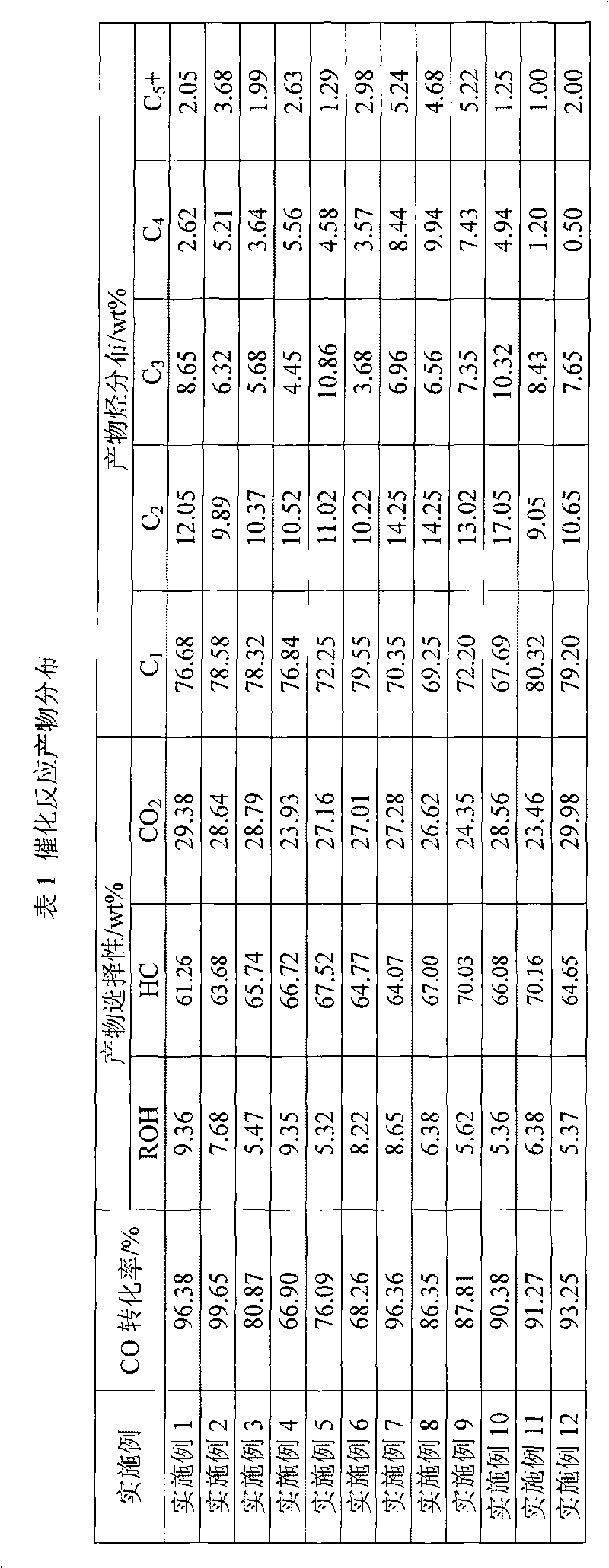

Examples

Embodiment 1

[0037] Formula: citric acid / (Ni+Mo) molar ratio is 1:0.5, Ni:Mo:TiO 2 The mass ratio is 1:10:30

[0038] TiO 2 The carrier was calcined at 400°C for 2 hours, and the preparation of the catalyst was carried out according to the formula as follows:

[0039] Under stirring conditions at 35°C, prepare citric acid, water / ethanol mixed solution (H 2 O / C 2 h 5 OH=1:10w / w), adjust the solution pH=1.5 with concentrated nitric acid; add Ni(NO 3 ) 3 ·6H 2 O solution and (NH 4 ) 6 Mo 7 o 24 4H 2 O solution, continue to stir for 14 hours, add the TiO after roasting treatment 2 Continue to stir for 5 hours, continue to evaporate the solvent at 60°C to a viscous solution, and dry the obtained product at 140°C for 4 hours to obtain Ni-Mo / TiO 2 Precursor. Grind the obtained precursor to a particle size of less than 0.25mm and place it in a quartz reaction tube, blow it with argon gas at a flow rate of 120mL / min, and use two-stage temperature program control to increase the temper...

Embodiment 2

[0041] Formula: citric acid / (Ni+Mo) molar ratio is 1:0.5, Fe:Mo:SiO 2 The mass ratio is 1:5:30

[0042] SiO 2 The carrier was calcined at 800°C for 24 hours, and the preparation of the catalyst was carried out according to the formula as follows:

[0043] Under stirring conditions at 20°C, prepare citric acid, water / ethanol mixed solution (H 2 O / C 2 h 5 OH=10:1w / w), adjust the solution pH=1.5 with concentrated nitric acid; add Fe(NO 3 ) 3 9H 2 O solution and (NH 4 ) 6 Mo 7 o 24 4H 2 O solution, continue to stir for 24 hours, add the calcined SiO 2 Continue to stir for 24 hours, continue to evaporate the solvent at 90°C to a viscous solution, and dry the obtained product at 140°C for 24 hours to obtain Fe-Mo / SiO 2 Precursor. Grind the obtained precursor to a particle size of less than 0.25mm and place it in a quartz reaction tube, and pass in argon gas at a flow rate of 150mL / min, and use two-stage temperature program control to increase the temperature from room ...

Embodiment 3

[0045] Formula: tartaric acid / (Co+Mo) molar ratio is 1:0.2, Co:Mo:Al 2 o 3 The mass ratio is 0.01:30:90

[0046] Al first 2 o 3 The carrier was roasted at 500°C for 12 hours, and the preparation of the catalyst was carried out according to the formula as follows:

[0047] Under the condition of stirring at 60°C, prepare a mixed solution of tartaric acid and water, adjust the pH of the solution to 1.5 with acetic acid; add Co(NO 3 ) 3 ·6H 2 O solution and (NH 4 ) 6 Mo 7 o 24 4H 2 O solution, continue to stir for 1 hour, add the Al after roasting treatment 2 o 3 Continue to stir for 1 hour, continue to evaporate the solvent at 60°C to a viscous solution, and dry the obtained product at 60°C for 24 hours to obtain Co-Mo / Al 2 o 3 Precursor. Grind the obtained precursor to a particle size of less than 0.25 mm and place it in a quartz reaction tube, blow nitrogen gas at a flow rate of 60 mL / min, and use two-stage temperature program control to increase the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com