Preparation method of nanometer aluminium hydroxide and application thereof

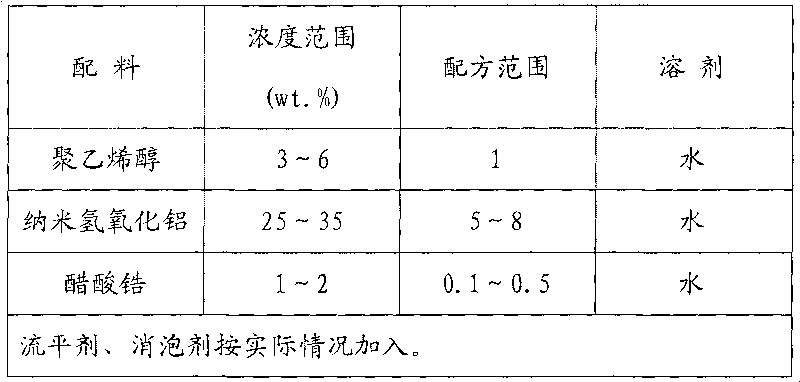

A nano-aluminum hydroxide, crystal seed technology, applied in the direction of alumina/aluminum hydroxide, can solve the problems of product quality and particle size difficult to control, and achieve the effects of bright colors, excellent adhesion and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

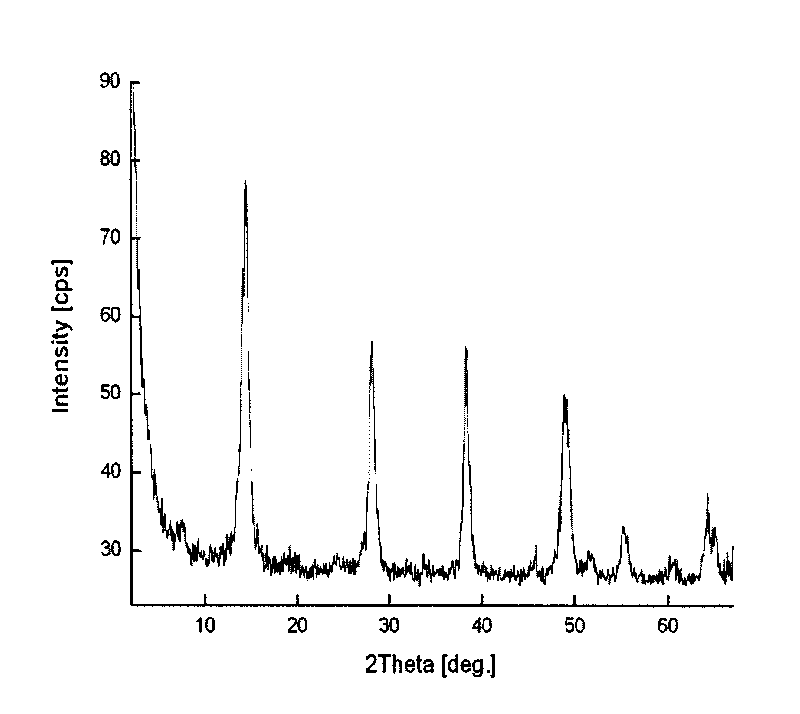

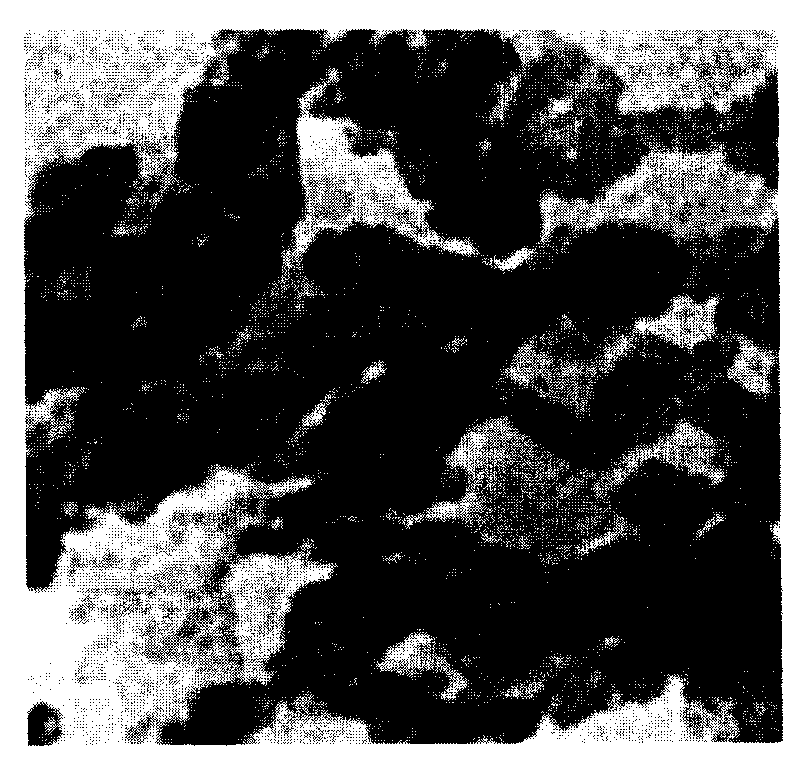

[0029] Preparation of Nano Aluminum Hydroxide

[0030] The present invention prepares the rough steps of nano aluminum hydroxide:

[0031] 1) Preparation of seed crystals

[0032] The preparation of seed crystals adopts the hydrolysis of aluminum methylate, and the hydrolysis of aluminum trimethoxide is carried out according to the following equation:

[0033] (CH 3 O) 3 Al+2H 2 O→AlOOH+3CH 3 Oh

[0034] The hydrolysis is carried out at a pH value of 2-4 and a temperature of 30-70°C.

[0035] 2) Post-treatment of seed crystals

[0036] The hydrolyzed aluminum hydroxide is washed several times by a high-speed centrifuge.

[0037] The washed intermediate product is dried by spray drying.

[0038] The dried powder is prepared into a 30% dispersion liquid, and then ground to 10-50nm by a double-barrel circulating nano-sand mill, and the nano-particles can be used as crystal seeds.

[0039] 3) adding inorganic aluminum salt and basic compound to the seed crystal for react...

Embodiment 1

[0053] In a 2-ton reactor, add 1.6 tons of water, start stirring and add 0.4 tons of aluminum methoxide, and then add about 40 kg of sulfuric acid to adjust the pH to 3.5. The temperature was raised to 50°C while stirring, and the reaction was carried out for 8 hours. Cool down to room temperature, discharge the material into a high-speed centrifuge for washing, and dehydrate. After the water is removed, add 1 ton of water for washing, and the washing can be completed by doing this 3 times. The dehydrated intermediate product was placed in a 3-ton stainless steel container, added with 2 tons of water to disperse for 1 hour, and dried by spray drying. The dried powder is mixed with water to make a 30% dispersion liquid, which is directly fed into a double-barrel circulating nano sand mill through a pipeline, and ground to a size of 10-50 nm, and the nano particles can be used as crystal seeds.

[0054] Add 1 ton of water into a 15-ton reactor, and add 0.2 tons of nano-aluminu...

Embodiment 2

[0059] Prepare nano-aluminum hydroxide seed and final nano-aluminum hydroxide product substantially by the same method described in Example 1, but differ from Example 1: the concentration of aluminum methylate increases to some extent, adds 0.8 ton in 1.6 tons of water of aluminum methoxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com