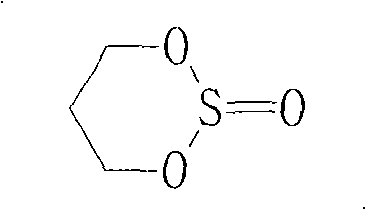

Catalytic ester exchange synthetic method of propylene sulfite and purification method

A technology of propylene sulfite and purification method, applied in organic chemistry and other directions, can solve the problems of multiple impurities, increase equipment investment, and high safety protection requirements, and achieve the effects of high reaction yield, easy reaction and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

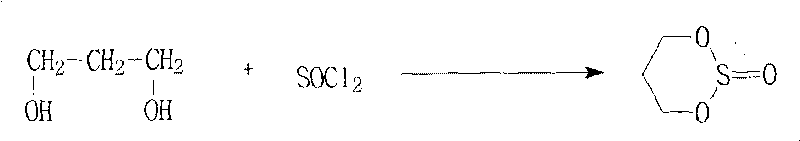

Problems solved by technology

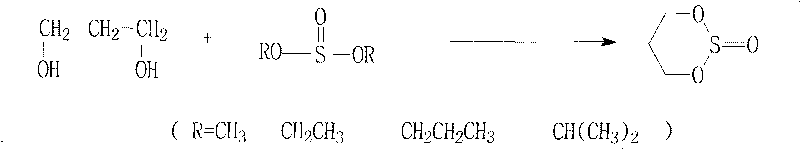

Method used

Image

Examples

Embodiment 1

[0032] Add 380g propylene glycol, 600g dimethyl sulfite, and 10g concentrated hydrochloric acid to a 1000ml three-necked flask equipped with an electric stirrer, distillation column and thermometer. Heat and stir the reaction. When the internal temperature reaches 70℃, there will be Methanol is distilled out from the rectifying column. As the reaction progresses, the internal temperature continues to rise. Keep the reaction temperature below 130°C until no more methanol is distilled out of the rectifying column, indicating that the reaction has been completed. Reaction time For 5 hours. 620 g of product was obtained. The reaction product was analyzed by gas chromatography. The composition of the product was 91.5% of propylene sulfite, 1.5% of propylene glycol, 1.8% of dimethyl sulfite, and 1.5% of methanol.

Embodiment 2

[0034] In a 1500 ml three-necked flask equipped with an electric stirrer, distillation column and thermometer, add 380g propylene glycol, 760g diethyl sulfite, 8g concentrated hydrochloric acid, heat and stir the reaction, when the internal temperature reaches 85 ℃, there will be Ethanol is distilled out from the rectifying column. As the reaction progresses, the internal temperature continues to increase. Keep the reaction temperature below 130°C until no more ethanol is distilled out of the rectifying column, indicating that the reaction has been completed. Reaction time Is 5.5 hours. 630 g of product was obtained. The reaction product was analyzed by gas chromatography. The product composition was: propylene sulfite 90.3%, propylene glycol 2.2%, diethyl sulfite 3.5%, and ethanol 2.1%.

Embodiment 3

[0036] Add 380g propylene glycol, 630g dimethyl sulfite, and 7.5g p-toluenesulfonic acid into a 1000ml three-necked flask equipped with an electric stirrer, distillation column and thermometer. Heat and stir the reaction. When the internal temperature reaches 70℃ , There is methanol distilled out from the rectifying column. As the reaction progresses, the internal temperature keeps increasing. Keep the reaction temperature below 130°C until no more methanol distills out of the rectifying column, indicating that the reaction has been completed , The reaction time is 4.5 hours. 625 g of product was obtained. The reaction product was analyzed by gas chromatography. The composition of the product was 92.3% propylene sulfite, 1.0% propylene glycol, 2.0% dimethyl sulfite, and 1.8% methanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com