Environmental-friendly new method for preparing N-phosphonomethyl iminodiacetic acid by utilizing acrylonitrile byproduct hydrocyanic acid

A technology of phosphonomethyl iminodiacetic acid and iminodiacetic acid, which is applied in the field of comprehensive utilization of hydrocyanic acid by-product of acrylonitrile plant, to achieve the effects of preventing polymerization and decomposition, high utilization rate, and improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

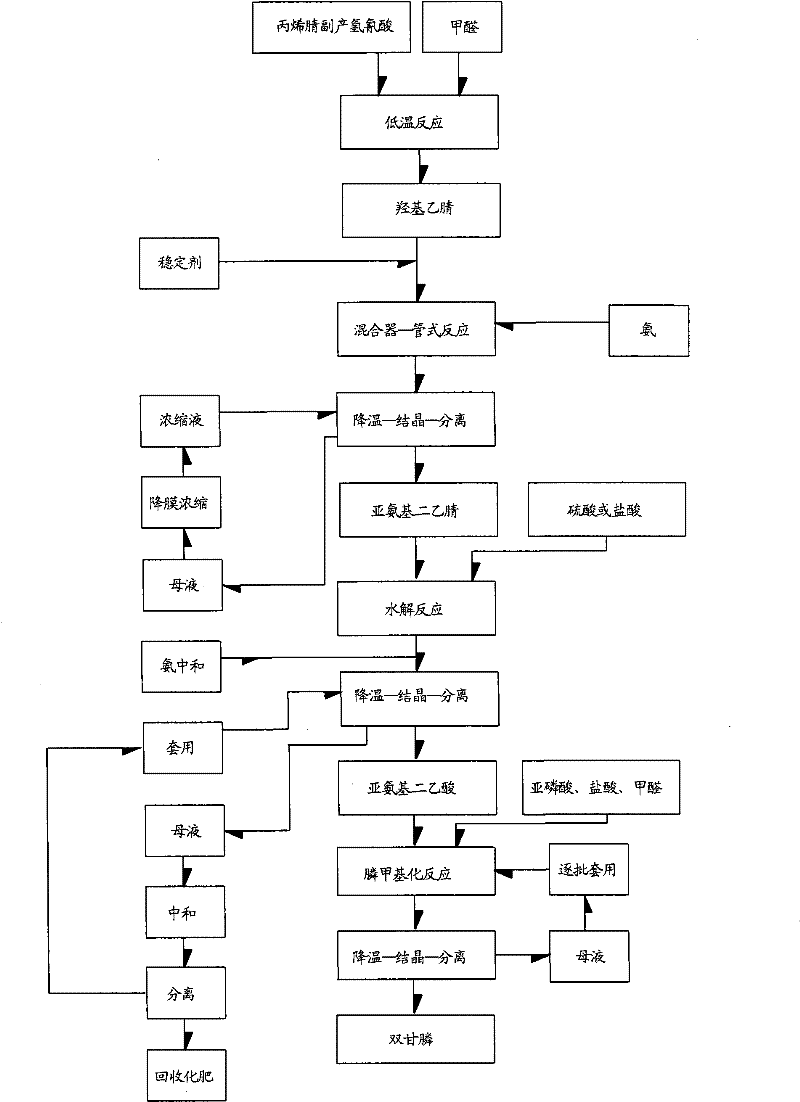

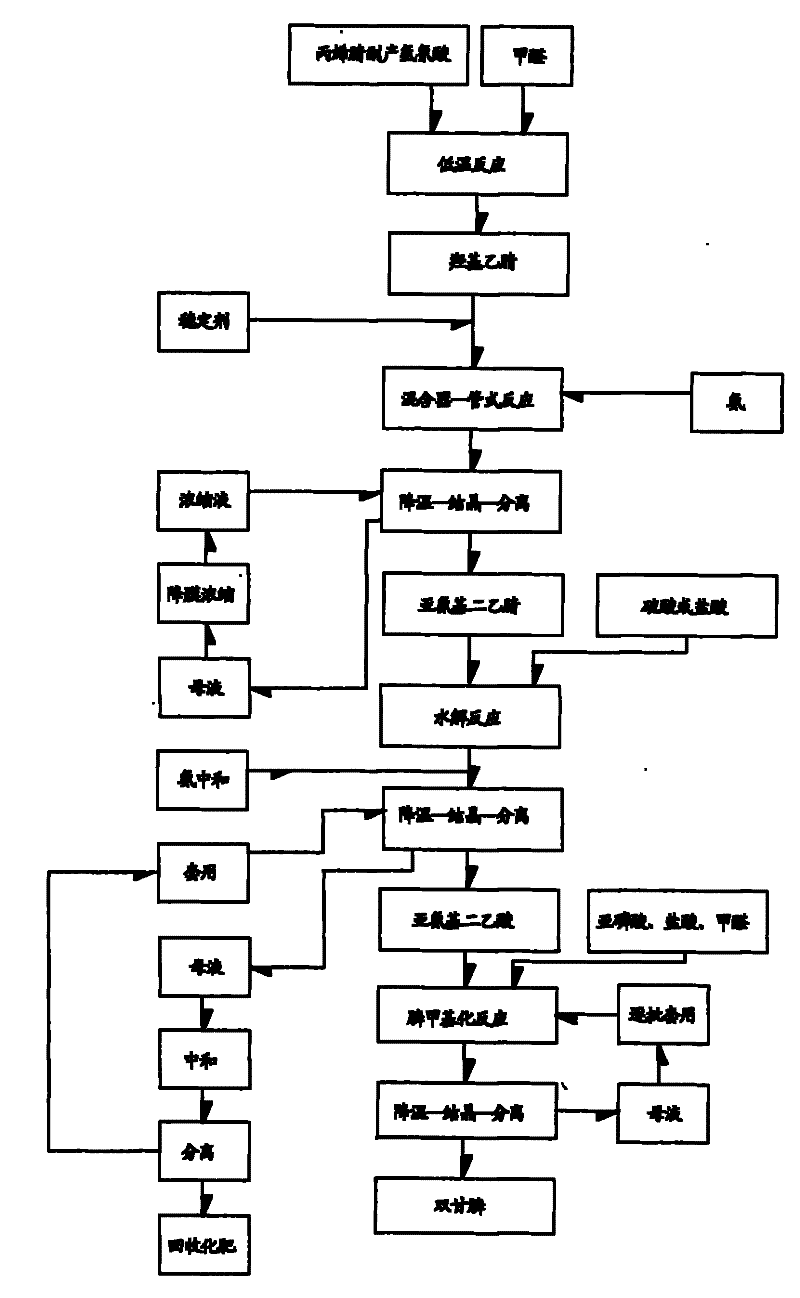

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: Hydrolysis of iminodiacetonitrile by hydrochloric acid method: hydrochloric acid=1: 2.5~5.0; Final draft

[0084] (1) Preparation of hydroxyacetonitrile

[0085] Molar ratio dosing: hydrocyanic acid: formaldehyde = 1:1

[0086] Hydrocyanic acid, a by-product of acrylonitrile in Qilu; formaldehyde was purchased from Qingzhou, Shandong; sodium sulfite, a reagent.

[0087] Dosage: Formaldehyde 25.0Kg (content 36%, pure 9.0Kg, 0.30kmol)

[0088] Hydrocyanic acid 8.14Kg (content 99.5%, pure 8.1Kg, 0.3kmol)

[0089] Sodium sulfite 37.8g (0.3mol)

[0090]In a 50L glass reactor, add 24.25Kg of formaldehyde, dissolve 37.8g of sodium sulfite with 750g of formaldehyde solution and add an appropriate amount of water, drop it into the reactor, stir well, turn on the interlayer of the refrigeration circulation pump to cool down the reaction material to 15°C, and put the frozen The preserved liquid hydrocyanic acid is added dropwise into the reaction bottle through a...

Embodiment 2

[0116] (1) Preparation of hydroxyacetonitrile

[0117] Molar ratio dosing: hydrocyanic acid: formaldehyde = 1: 1.1

[0118] Hydrocyanic acid, a by-product of acrylonitrile in Qilu; formaldehyde was purchased from Qingzhou, Shandong; sodium sulfite, sodium bisulfite, reagents.

[0119] Dosage: Formaldehyde 22.92g (content 36%, pure 8.25Kg, 0.275kmol)

[0120] Hydrocyanic acid 6.78Kg (content 99.5%, pure 6.75Kg, 0.25kmol)

[0121] Sodium sulfite 189g (1.5mol) Sodium bisulfite 104g (1.0mol)

[0122] Operating procedure is with embodiment 1.

[0123] Keep the temperature at 20-25°C, stir and react for 1 hour, take a sample to measure the content of free cyanide as 0, and the content of formaldehyde as 0001%, adjust the pH to 3.0 with concentrated sulfuric acid. Kg, the yield is 99.44%.

[0124] (2) Preparation of iminodiacetonitrile

[0125] Add 29Kg of the obtained hydroxyacetonitrile to 58g of ZSM5 zeolite powder and mix evenly, prepare the iminodiacetonitrile procedure ac...

Embodiment 3

[0131] (1) Preparation of hydroxyacetonitrile

[0132] Molar ratio dosing: hydrocyanic acid: formaldehyde = 1: 1.05

[0133] Hydrocyanic acid, a by-product of acrylonitrile in Qilu; formaldehyde was purchased from Qingzhou, Shandong; ammonium sulfite, a reagent.

[0134] Dosage: Hydrocyanic acid 8.14Kg (content 99.5%, pure 8.1Kg, 0.3kmol)

[0135] Formaldehyde 26.25Kg (content 37%, pure 9.45Kg, 0.315kmol)

[0136] Ammonium sulfite 174g (1.5mol)

[0137] In a 501 glass reactor, add 26.25Kg of formaldehyde, dissolve 174g of ammonium sulfite with 1500g of water, drop it into the reactor, stir well, turn on the interlayer of the refrigeration circulation pump to lower the temperature of the reaction material to 15°C, and freeze the preserved liquid Hydrocyanic acid is added dropwise into the reaction bottle through a constant pressure dropping funnel, and the reaction temperature is kept at 15-25°C during the dropping process. The content is 0, the formaldehyde content is 0.03...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com