Preparation method for supercritical anti-solvent of water-soluble nano glycyrrhizic acid powder

A technology of supercritical anti-solvent and glycyrrhizic acid powder, which is applied to medical preparations containing active ingredients, digestive system, powder delivery, etc. It can solve the problems of destroying drug structure, wide particle distribution, and difficulty in making pharmaceuticals, and achieve powder quality High, narrow particle size distribution and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

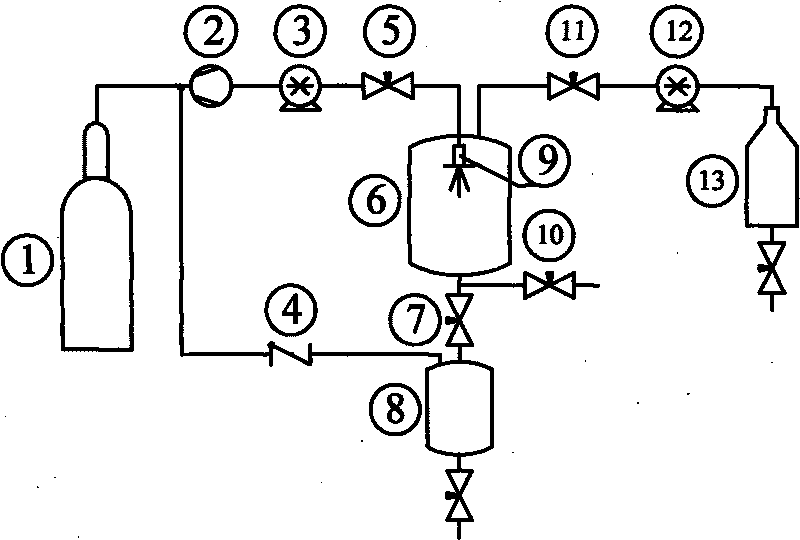

[0022] Accurately weigh 1 g of glycyrrhizic acid, dissolve it in 100 ml of absolute ethanol, open the valve 3, start the high-pressure liquid pump 4, pressurize the high-pressure crystallization kettle to 20Mpa, heat up to 55°C, adjust the flow control valve 10, start the high-pressure liquid pump 6, Through the nozzle 9, the absolute ethanol solution of glycyrrhizic acid is sprayed into the high-pressure crystallization chamber. Close valve 10 and valve 3, run for 50 minutes to relieve pressure, and obtain glycyrrhizic acid powder with an average particle size of 150nm.

example 2

[0024] Accurately weigh 1 g of glycyrrhizic acid, dissolve it in 150 ml of countless ethanol, open valve 3, start high-pressure liquid pump 4, pressurize the high-pressure crystallization kettle to 15Mpa, heat up to 46 ° C, adjust flow control valve 10, start high-pressure liquid pump 6, pass Nozzle 9 sprays the dehydrated ethanol solution of glycyrrhizic acid into the high-pressure crystallization chamber. Close valve 10 and valve 3, run for 50 minutes to relieve pressure, and obtain glycyrrhizic acid powder with an average particle size of 220nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com