Device and method for rapidly realizing and stably maintaining shortcut nitrification in continuous flow process

A short-range nitrification and rapid technology, applied in the direction of chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problem of high energy consumption of aeration, achieve high denitrification rate, efficient destruction, indestructible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

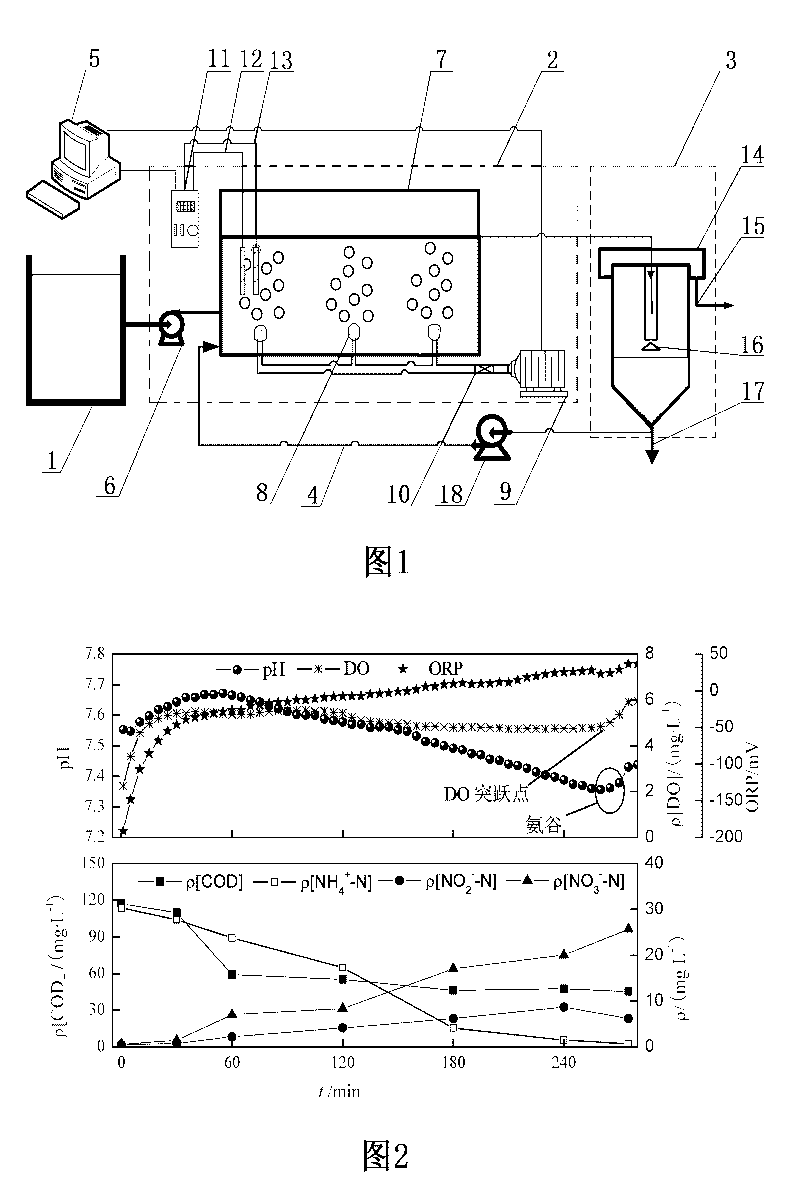

[0036] Embodiment 1 Referring to Figure 1, a device for quickly realizing and stably maintaining short-cut nitrification in a continuous flow process, in which a water inlet tank 1, an aeration system 2, and a sedimentation system 3 are sequentially set up in the order from the water inlet end to the water outlet end . The water inlet tank 1 is connected to the fully mixed reaction tank 7 through the water inlet pump 6, and the water outlet above the completely mixed reaction tank 7 is connected to the sedimentation tank 14 through a pipeline. The volume of the mixed reaction cell. The settling tank 14 is a radial-flow settling tank with central water inlet and peripheral water outlet. The water inlet pipe is at the center, and the water outlet weir is at the periphery and is connected with a system water outlet 15 . A fender 16 is set in the sedimentation tank, and the bottom of the sedimentation tank is connected to the excess sludge port 17 to remove part of the sludge, an...

Embodiment 2

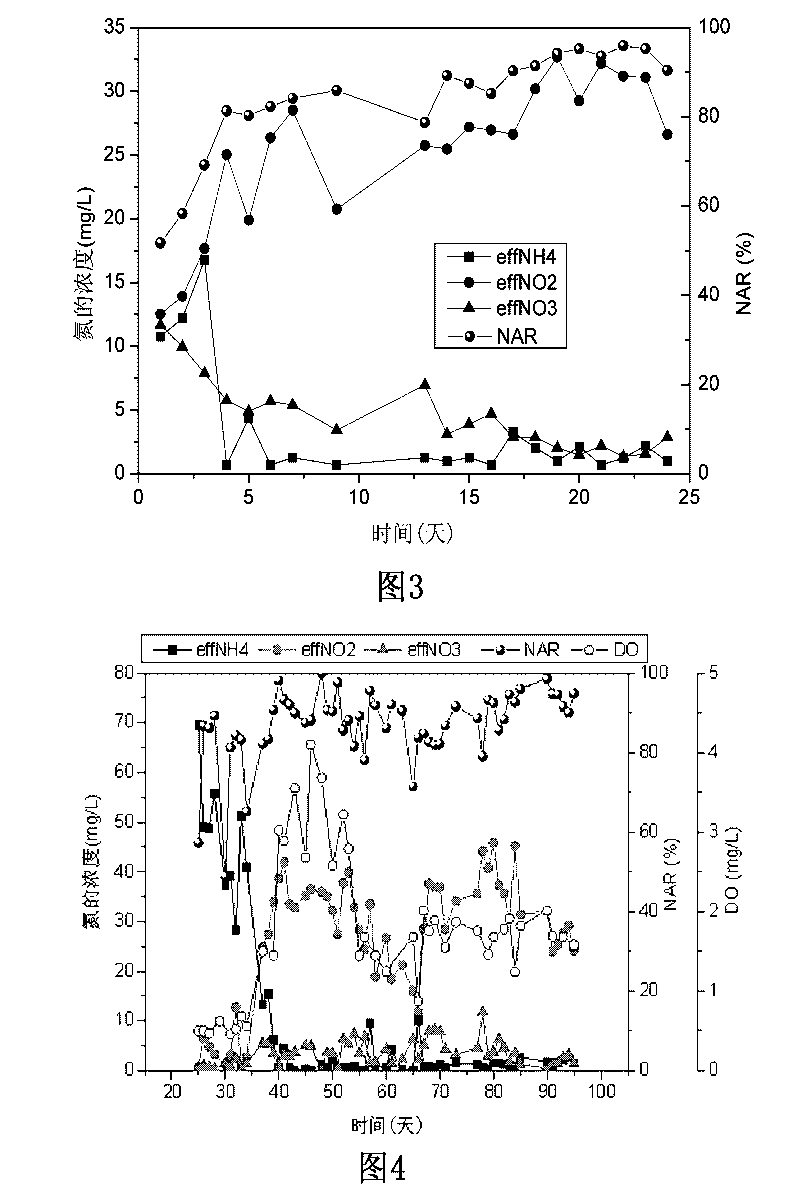

[0038] Embodiment two is referring to shown in Figure 3, the fast start of short-range nitrification, with the septic tank sewage of a college living area in Beijing as raw water, influent COD, ammonia nitrogen, total nitrogen (COD=160-320mg / L, NH 4 + -N=46.8-75.6mg / L, TN=49.4-85.4mg / L), COD, NH during the test phase 4 + The average influent concentrations of -N and TN were 215mg / L, 59.7mg / L and 64.5mg / L.

[0039] By monitoring the characteristic points on the pH and DO curves of the aerobic phase every cycle, and using aerobic aeration to control and stop the aeration in real time, obvious NO gradually appeared in the reaction tank at the end of each cycle 2 - -N accumulation. During the batch culture, it took only 24 days, the NO in the reaction pool 2 - -N accumulation rate (NAR) increased from 51.7% at the beginning to 95.2%.

Embodiment 3

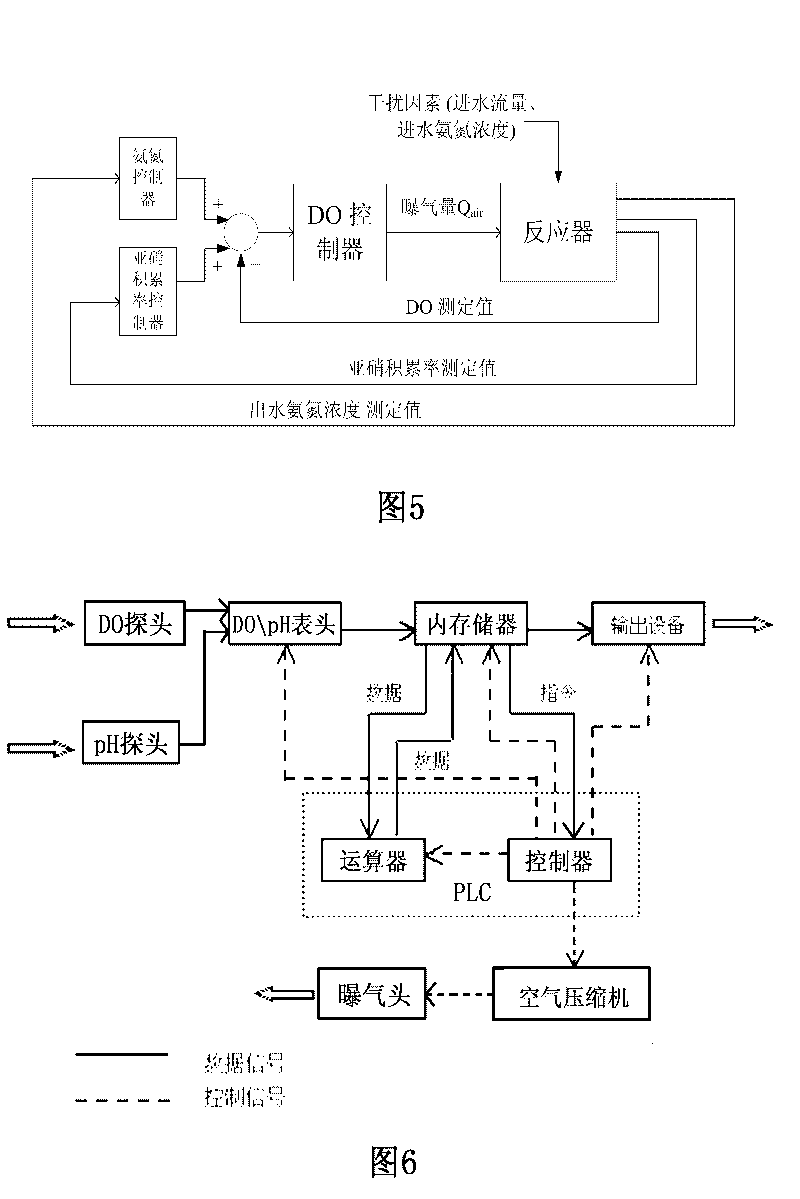

[0040] Embodiment three see Figure 4 As shown, the stable maintenance of short-cut nitrification in continuous flow, using the septic tank sewage of a college living area in Beijing as raw water, influent COD, ammonia nitrogen, total nitrogen (COD=160-320mg / L, NH 4 + -N=46.8-75.6 mg / L, TN=49.4-85.4 mg / L). Using the device mentioned in the present invention, the hydraulic retention time (HRT) of the fully mixed reaction tank is set to 4h, and the sludge return ratio is 100%. The stable maintenance of short-cut nitrification of this process was tested using dissolved oxygen (DO) as the control parameter of the fully mixed reaction tank.

[0041] COD, NH in the test stage 4 + The average influent concentrations of -N and TN were 215mg / L, 59.7mg / L and 64.5mg / L. During the test, the concentration of DO was monitored online, and according to the NH concentration in the effluent 4 + -N and NO 2 - -N concentration adjusts the aeration rate. When the DO is controlled at abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com