Physicochemical and biochemical treatment method of chemical copper plating waste water

A technology for electroless copper plating and biochemical treatment, applied in metallurgical wastewater treatment, chemical instruments and methods, oxidized water/sewage treatment, etc. Guaranteed, strong adsorption, the effect of reducing the treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

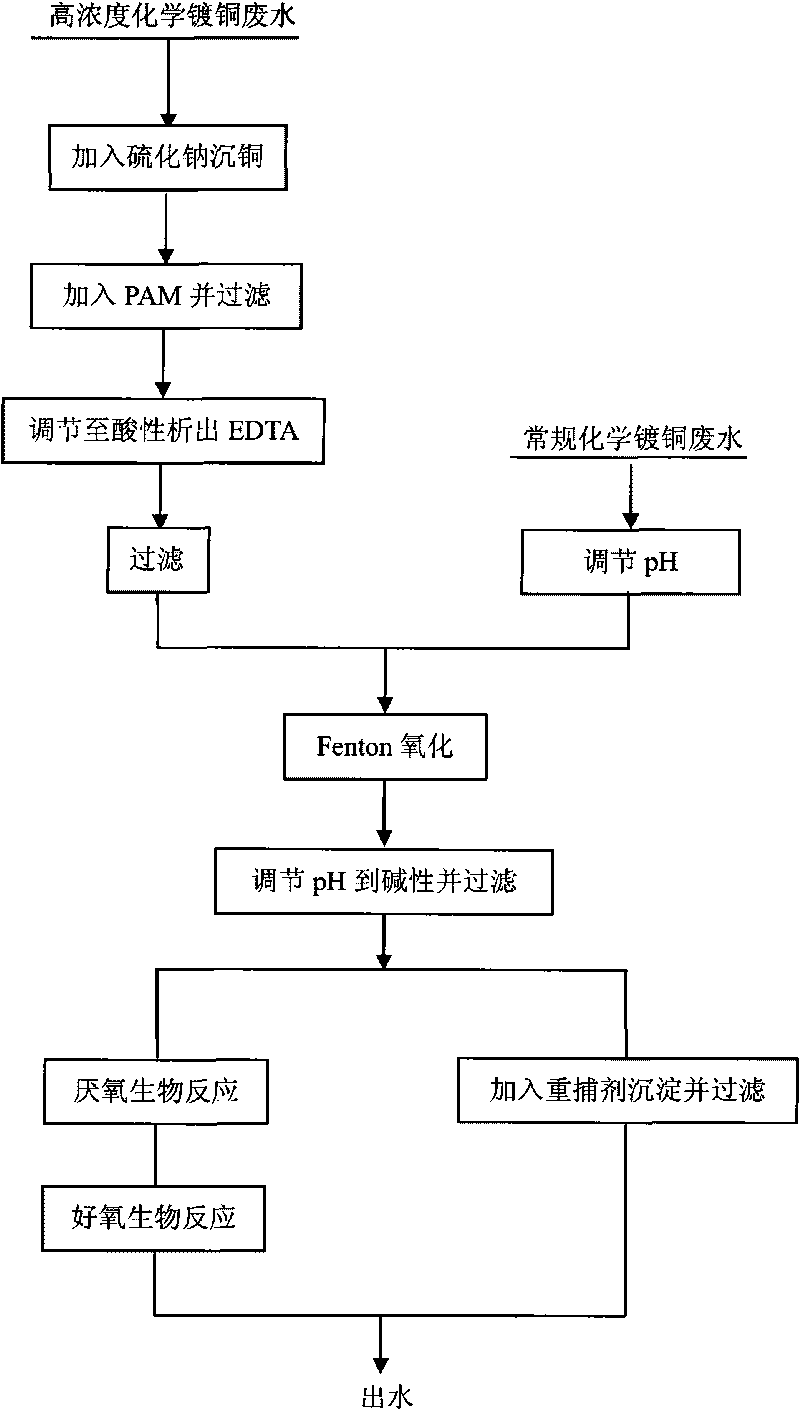

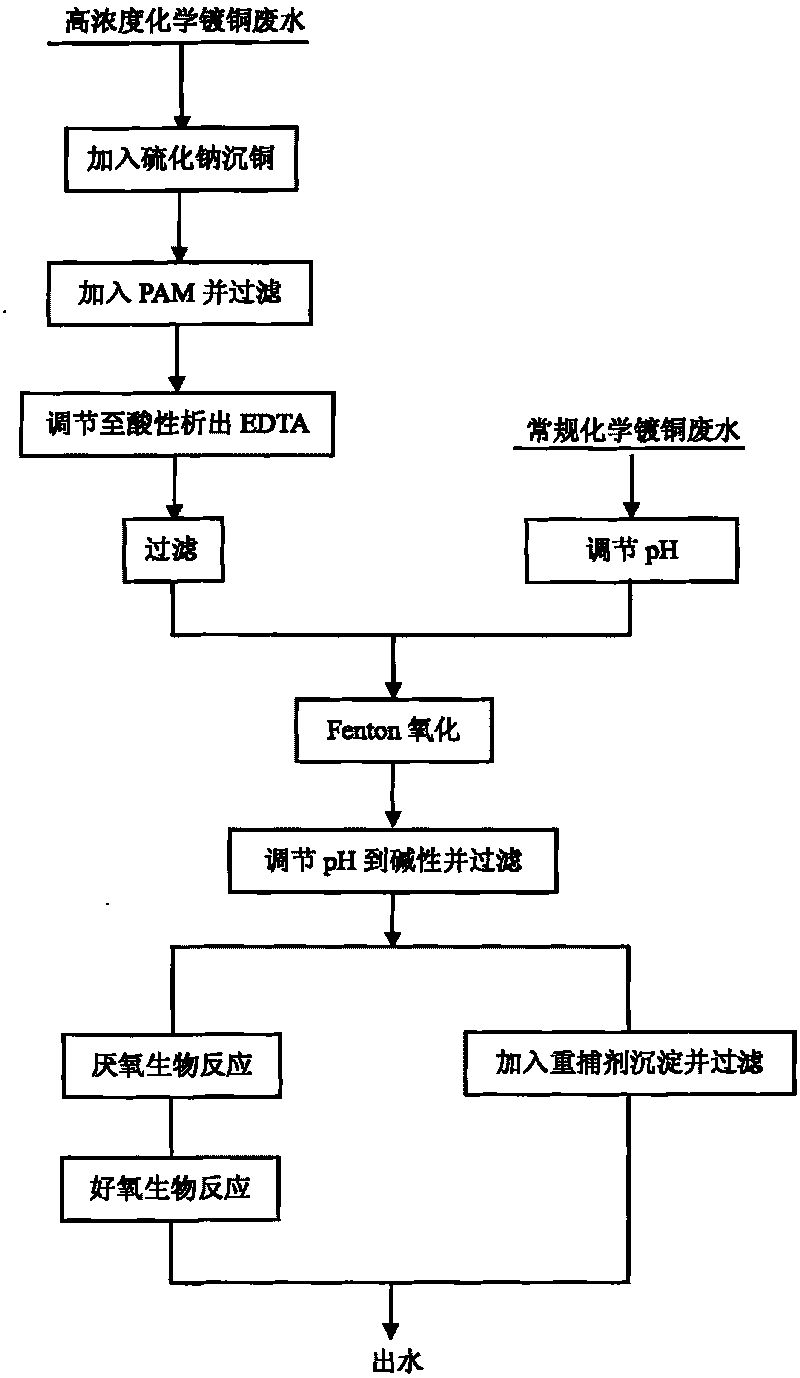

Method used

Image

Examples

example 1

[0054] Example 1 Treatment of Conventional Electroless Copper Plating Wastewater

[0055] Get 500ml of electroless copper plating wastewater, its water quality parameters are shown in Table 1, the pH value of the wastewater is adjusted to about 3.5, according to the COD Cr Add 15ml of hydrogen peroxide (30%) thereto at the ratio of concentration 1.5:1, and add 1g of ferrous sulfate heptahydrate therein, adopt the mode of magnetic stirring to react for 1 hour, adjust the pH to 7.5, and add about 10ml of PAM ( Concentration 1‰) to stand still for 10 minutes and filter, then add DTCR heavy metal scavenger to the effluent water according to the ratio of 20-30 times the residual heavy metal ions (about 60g / t), and add appropriate amount of PFS and PAM to it and stir for 15 minutes, then Filter out the water.

[0056] After the wastewater is treated, the relevant water quality parameters of the effluent are as follows:

[0057] Table 3 Water quality parameters after conventional e...

example 2

[0059] Example 2 Treatment of High Concentration Electroless Copper Plating Wastewater

[0060] Take 500ml of conventional electroless copper plating wastewater, add 3.0g of sodium sulfide to magnetically stir for 10min and filter, then adjust the pH to below 2.0 to precipitate EDTA, magnetically stir for 30min and filter the precipitated material, enter the Fenton oxidation stage, add 75ml of hydrogen peroxide to the wastewater (30%) and 2g of ferrous sulfate heptahydrate were magnetically stirred for 1 hour, after the reaction was complete, the pH was adjusted to about 7.5, and 20ml of PAM (concentration 1‰) was added thereto and left to stand for 10min before filtering. At this point, the physical and chemical treatment of waste water is completed, and it enters the biological reaction section after being diluted by 3 times. The residence time of the anaerobic reaction section is controlled at 6 days, the feed is 500ml per day, the pH is controlled between 7-8, and the stir...

example 3

[0063] Example 3 Treatment of Mixed Electroless Copper Plating Wastewater

[0064] Circuit board manufacturers often mix various types of wastewater into the same wastewater pool after the wastewater is generated. The wastewater not only includes electroless copper plating wastewater, but may also contain other types of wastewater. The nature of the mixed wastewater will be more complicated. Therefore, for this The research on similar wastewater will have greater practical significance. The water quality parameters of representative water samples are as follows:

[0065] Table 5 Water quality parameters of mixed electroless copper plating wastewater

[0066] project

pH

Formaldehyde (mg / l)

EDTA (g / l)

COD Cr (mg / l)

Cu(mg / l)

Ni(mg / l)

concentration

8.0

not detected

0.68

1258.03

913.00

15.10

[0067] The present invention learns from the treatment process similar to high-concentration electroless copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com