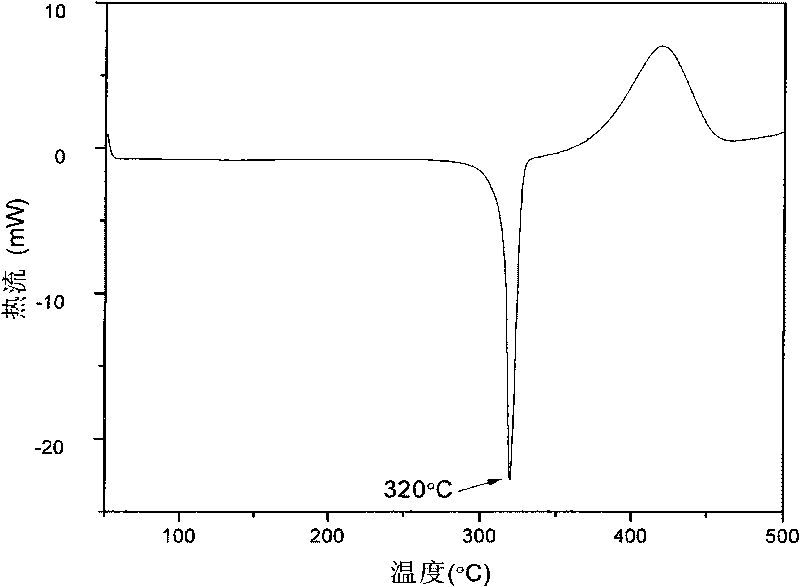

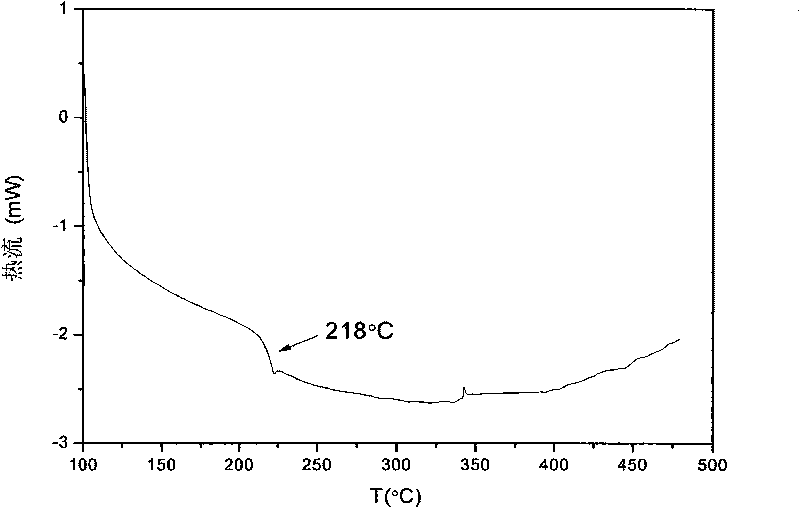

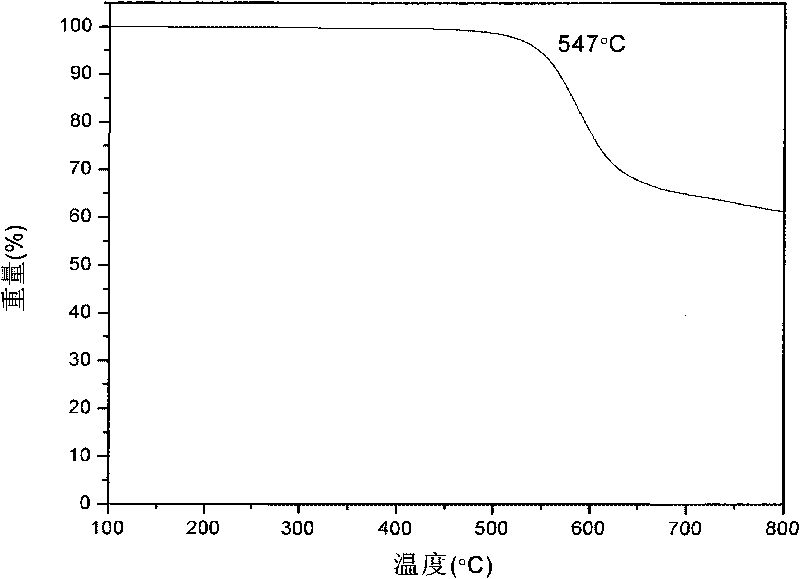

Phenylacetylene-capped polyether-ether-ketone oligomer and preparation method thereof

A technology of polyetheretherketone and phenylacetylene, applied in the field of polyetheretherketone oligomers, polyetheretherketone oligomers and their preparation, to achieve excellent processing performance, high heat resistance, and excellent heat resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Specific examples of the preparation of hydroxyl-terminated polyether ether ketone oligomers

[0051] 4,4'-difluorobenzophenone (21.82g, 0.1mol), p-hydroxyanisole (26.07g, 0.21mol), anhydrous potassium carbonate (30.43g, 0.2205mol) and N,N-dimethyl Dimethyl formamide (DMF) (200ml), toluene (60ml) is put into the 1000ml three-necked flask that is equipped with mechanical stirring, nitrogen vent, water device, reflux condenser, toluene is refluxed 2 hours, heats up and evaporates toluene, The reaction temperature was controlled at 145° C., and the reaction was continued for 4 hours. Finally, the material is discharged into an aqueous hydrochloric acid solution, washed with deionized water until the aqueous solution is neutral, and then washed three times with ethanol to obtain the initial oligomer, which is dried for later use. The initial oligomer (10.0g) obtained above, hydroiodic acid (50ml) and acetic acid (200ml) are joined in the 250ml three-neck flas...

Embodiment 2

[0052] Embodiment 2: Specific examples of preparation of polyetheretherketone oligomers terminated by phenylacetylene

[0053] The synthesis method adopted in this example is a two-step method. Wherein the process of the first step is described in embodiment 1; Below is the second step.

[0054] The hydroxyl-terminated polyetheretherketone oligomer (1.99g, 0.005mol) obtained in Example 1, anhydrous potassium carbonate (0.8g, 0.0058mol) and N-methylpyrrolidone (NMP) (20ml), toluene (10ml) is put into the 100ml three-neck flask that mechanical stirring, nitrogen vent, belt water device, reflux condenser are housed, toluene refluxes 2 hours, heats up and evaporates toluene, controls reaction temperature 180~190 ℃, continues reaction 4 Hour. Then add 4-fluoro-4'-phenylethynylbenzophenone (FPEB) (0.0105mol, 3.15g), control the reaction temperature at 160-170°C to continue the reaction for 4 hours, and finally discharge the material into an aqueous hydrochloric acid solution, and ...

Embodiment 3

[0055] Embodiment 3: Specific examples of preparation of polyetheretherketone oligomers terminated by phenylacetylene

[0056] The synthesis method adopted in this example is a one-step method. Put biphenyldiphenol (0.9311g, 0.005mol), potassium carbonate (1.38g, 0.01mol) and N-methylpyrrolidone (NMP) (20ml), toluene (10ml) into a device equipped with mechanical stirring, nitrogen vent, In a 100ml three-necked flask with a water device and a reflux condenser, the toluene was refluxed for 2 hours, the temperature was raised and the toluene was evaporated, the reaction temperature was controlled at 180-190° C., and the reaction was continued for 4 hours. Then add 4-fluoro-4'-phenylethynylbenzophenone (FPEB) (0.0105mol, 3.15g), control the reaction temperature at 160-170°C to continue the reaction for 4 hours, and finally discharge the material into an aqueous hydrochloric acid solution, and use Wash with deionized water until the aqueous solution is neutral, then wash with etha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com