Cefodizime sodium crystal form and preparation method thereof as well as drug compound comprising crystal form

A technology of cefodizime sodium and a composition is applied in the field of preparation of pharmaceutical compounds, can solve the problems of high ethanol residue, high organic residue, low specific density and the like, and achieves the effects of easy operation, equipment saving and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

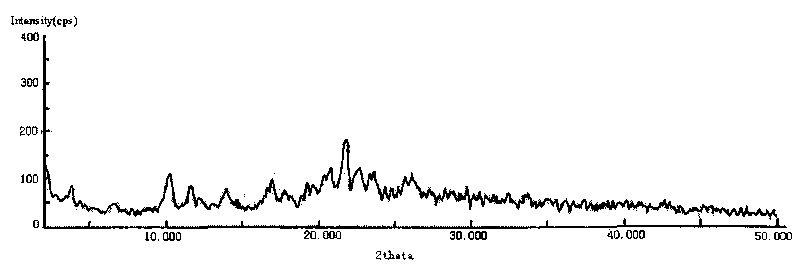

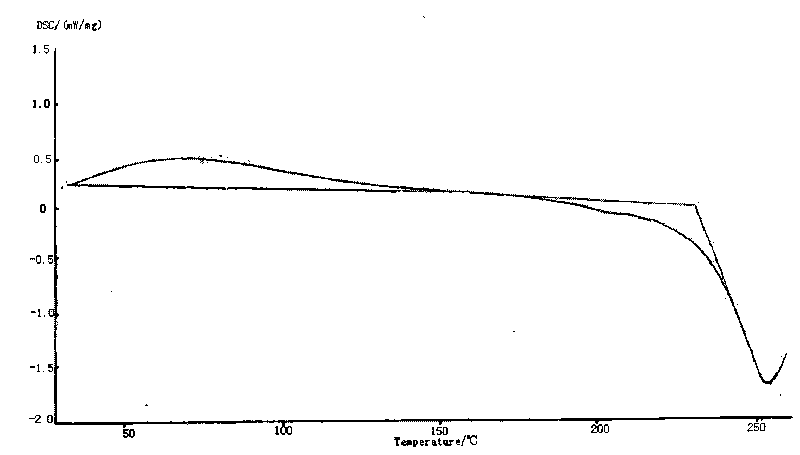

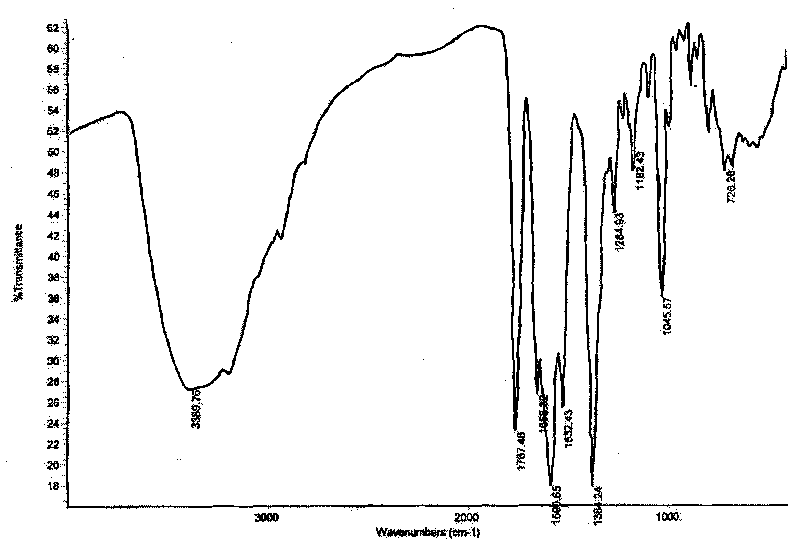

[0032] Take 5 g of cefodizime crude sodium salt sample, add it to 12.5 ml of purified water, and stir at room temperature until it dissolves completely. The solution was then placed in an ice bath and cooled to about 0 °C. Slowly drop 200ml of absolute ethanol into the above solution, and at the same time stir at a stirring speed of 250rpm until the solids are completely precipitated, filter with suction, wash the filter cake with acetone, and then vacuum-dry to constant weight to obtain 3.7g of granular cefodizime sodium crystals product. The resulting product X-ray diffraction pattern is as figure 1 As shown, its differential thermal analysis spectrum is shown as figure 2 As shown, its infrared spectrum is shown as image 3 shown.

[0033] The obtained cefodizime sodium crystal form product and the commercially available cefodizime sodium sample are carried out organic residue test, and gas chromatography analysis result shows that ethanol and acetone residual content a...

Embodiment 2

[0035] Take 5 g of cefodizime sodium salt sample, add it to 20 ml of methanol purified aqueous solution with a volume fraction of 50% (V / V), and stir at room temperature until completely dissolved. The solution was then placed in an ice bath and cooled to about 10°C. Slowly drop 300ml of ethanol into the above solution, and at the same time stir at a stirring speed of 200rpm until the solid is completely precipitated, filter with suction, wash the filter cake with acetone and vacuum dry to constant weight to obtain 3.6g of granular cefodizime sodium crystal form product. The X-ray diffraction pattern, differential thermal analysis pattern, and infrared spectrogram of the obtained product are basically consistent with Example 1; the residual content of methanol is less than 0.3%, and the residual content of ethanol and acetone is less than 0.5%, which meets the technical guidance of the national chemical drug residual solvent research. Standards established in principle (methan...

Embodiment 3

[0037] Take 5 g of cefodizime sodium salt sample, add 15 ml of 25% (V / V) methanol purified aqueous solution, and stir at room temperature until completely dissolved. The solution was then placed in an ice bath and cooled to about 5 °C. Slowly drop 200ml of acetone into the above solution, and at the same time stir at a stirring speed of 300rpm until the solid is completely precipitated, filter with suction, wash the filter cake with acetone and vacuum dry to constant weight to obtain 3.8g of granular cefodizime sodium crystal form product. Gained product X-ray diffraction pattern, differential thermal analysis pattern, infrared spectrogram are basically consistent with embodiment 1; Residual content of methanol is less than 0.3%, and residual content of acetone is less than 0.5%, conforms to the technical guideline of national chemical drug residual solvent research and formulates standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com