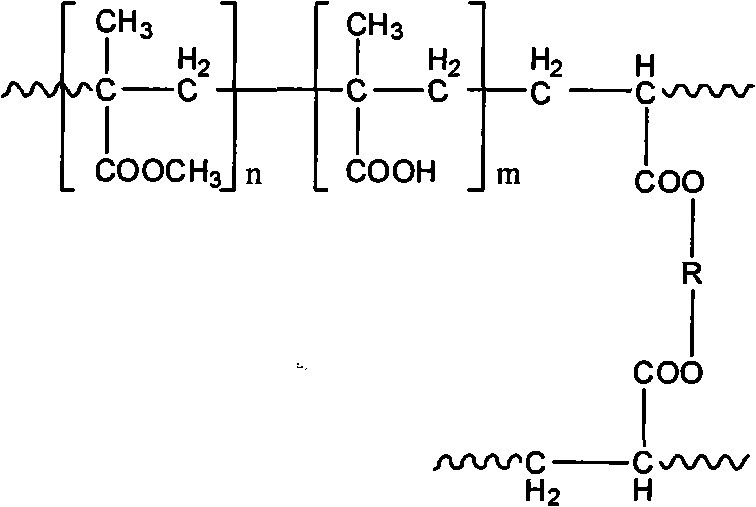

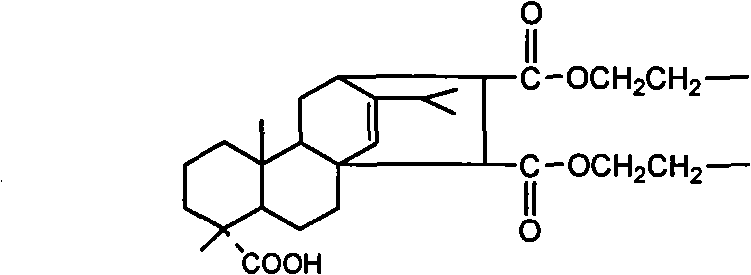

Abietyl-containing terpolymer and preparation method thereof

A technology of terpolymers and copolymers, applied in the field of high molecular polymers and their preparation, can solve the problems of unreported preparation methods, and achieve the effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

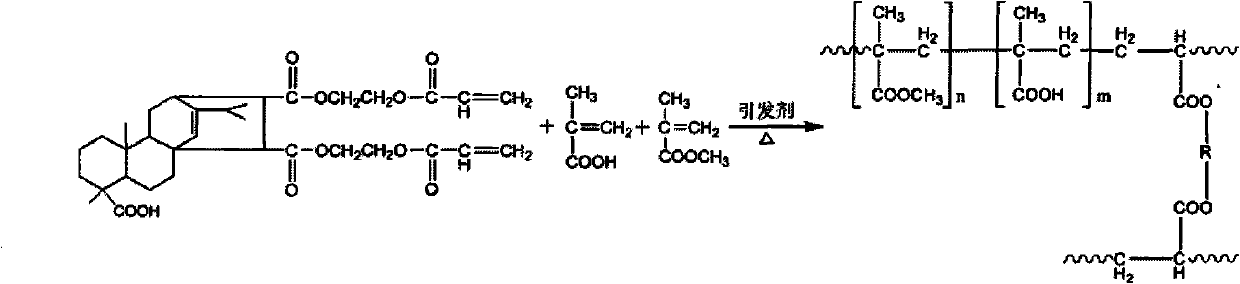

Method used

Image

Examples

Embodiment 1

[0029] Take by weighing 34.5g maleic rosin ethylene glycol acrylate, be dissolved in 138g ethyl acetate, use ultrasonic wave to promote dissolution, after cross-linking agent dissolves completely, then add 47g methacrylic acid, 2.3g methyl methacrylate, 27g of soybean oil and 4g of azobisisobutyronitrile were oscillated by ultrasonic waves for 10 minutes to disperse evenly to obtain an oil phase; another 510g of distilled water was added to a three-necked flask, and 0.5g of sodium lauryl sulfate was added and mixed to obtain a water phase Mutually. Adjust the stirring speed to 300rpm, and add the fully dissolved oil phase to the water phase at a constant stirring speed. After adding the organic phase, the system is pre-dispersed at room temperature for 10 minutes to form a better dispersion system. Start slowly heating up, and react at a constant temperature at 80°C 20min, the heating rate is 5°C / 10mim; then the temperature is raised to 95°C at the same heating rate, and the t...

Embodiment 2

[0032] Weigh 34.5g of maleic rosin ethylene glycol acrylate, dissolve it in 35g of ethyl acetate, and use ultrasonic waves to promote dissolution. After the crosslinking agent is completely dissolved, add 0.5g of acrylic acid, 13g of methyl methacrylate, 2.4g of Soybean oil and 0.24g of benzoyl peroxide were oscillated by ultrasonic waves for 10 minutes to disperse evenly to obtain an oil phase; another 680g of distilled water was added to a three-necked flask, and 0.07g of sodium lauryl sulfate was added and mixed to obtain an aqueous phase . Adjust the stirring speed to 250rpm, add the fully dissolved oil phase to the water phase at a constant stirring speed, according to the operation of Example 1, after the reaction is completed, filter, wash with 95 ° C distilled water until the washing liquid is clear, and obtain horse Lyrosin ethylene glycol acrylate-acrylic acid-methyl methacrylate copolymer.

[0033] The obtained maleated rosin ethylene glycol acrylate-acrylic acid-m...

Embodiment 3

[0035] Weigh 517g maleic rosin ethylene glycol acrylate, dissolve in 765g ethyl acetate, use ultrasonic wave to promote dissolution, after the crosslinking agent is completely dissolved, then add 425g methacrylic acid, 135g methyl methacrylate, 127g large Soybean oil and 27.45g of azobisisobutyronitrile were ultrasonically oscillated for 10 minutes to disperse evenly to obtain an oil phase; another 6.75kg of distilled water was added to a 20L reaction kettle, and 3.85g of sodium lauryl sulfate was added and mixed evenly to obtain water box. Adjust the stirring speed to 350rpm, and add the fully dissolved oil phase to the water phase at a constant stirring speed, according to the operation of Example 1, after the reaction is completed, filter, wash with 90 ° C distilled water until the washing liquid is clear, and obtain horse Lyrosin ethylene glycol acrylate-methacrylic acid-methyl methacrylate copolymer.

[0036] The obtained maleated rosin ethylene glycol acrylate-methacryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com