Method for preparing light absorption layer of CIGS (copper indium gallium selenide) thin film solar cell by magnetron sputtering method

A technology for thin-film solar cells and light-absorbing layers, applied in sputtering plating, coatings, circuits, etc., can solve problems such as large differences, changes, difficult control of film uniformity and repeatability, etc., and achieve high-quality and uniform film quality The effect of good performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

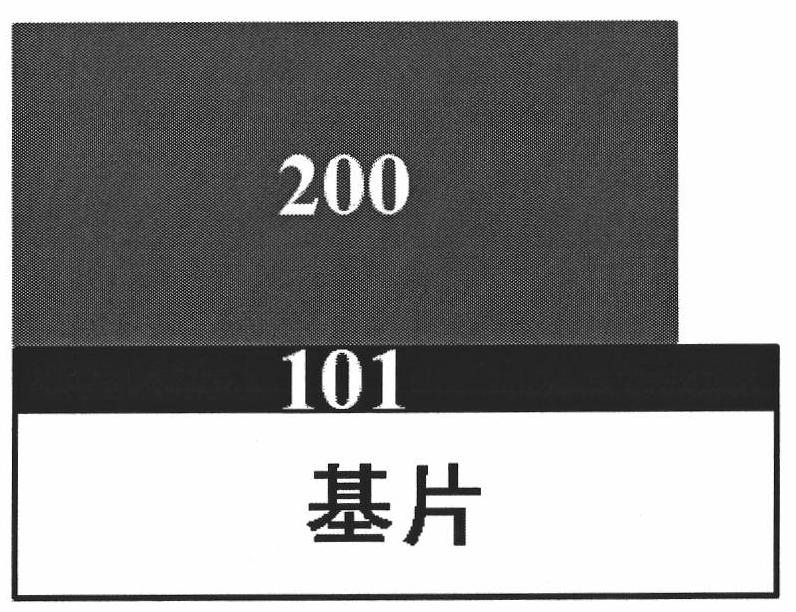

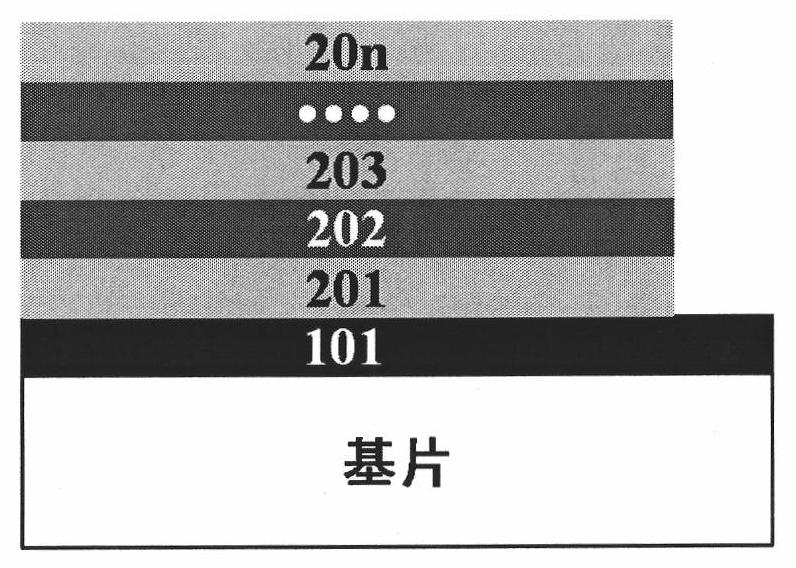

Method used

Image

Examples

Embodiment 1

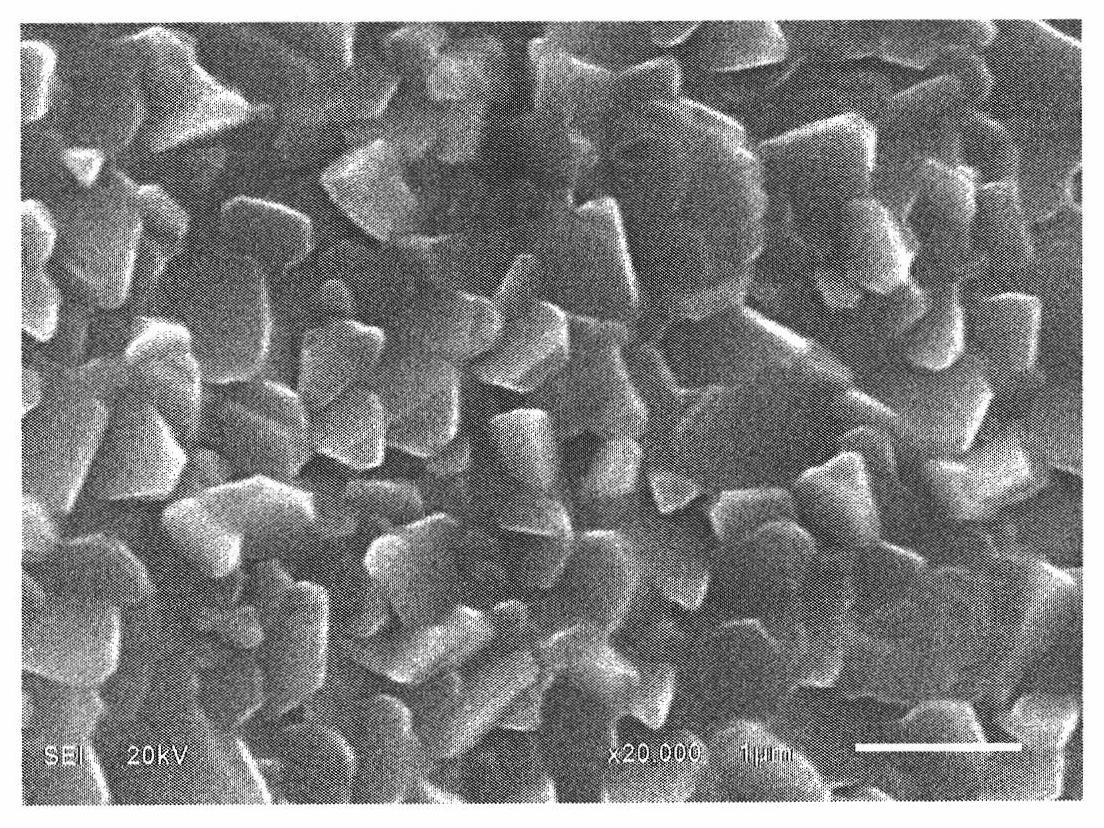

[0042] Preparation of CIGS precursor thin film: on molybdenum-coated soda lime silica glass, with Cu 0.9 In 0.8 Ga 0.2 Se 1.95 As a target, the CIGS precursor film was prepared by radio frequency sputtering, and the sputtering power density was 1.2Wcm -2 , the target distance is 7cm, the working pressure is 1.2Pa; the thickness of the prepared CIGS precursor film is 1200nm, due to the difference of element sputtering rate, in the prepared CIGS precursor film Cu / (In+Ga)=0.86, Ga / (In+Ga) = 0.20.

[0043] Heat treatment of CIGS precursor film: In 30000Pa nitrogen, heat the solid elemental Se source to 230°C to form the saturated vapor pressure of Se, place the CIGS precursor film in the saturated Se vapor pressure, and heat the CIGS at a heating rate of 30°C / min. The precursor film is heated to 530° C. and kept for 30 minutes to prepare the desired CIGS light-absorbing layer.

Embodiment 2

[0045] Preparation of CIGS precursor film: on a molybdenum-coated ceramic plate, with Cu 0.7 In 0.6 Ga 0.4 Se 1.85 As a target, the CIGS precursor film was prepared by radio frequency sputtering, and the sputtering power density was 0.2Wcm -2 , the target distance is 4cm, the working pressure is 0.05Pa; the thickness of the prepared CIGS precursor film is 500nm, due to the difference of element sputtering rate, in the prepared CIGS precursor film, Cu / (In+Ga)=0.67, Ga / (In+Ga) = 0.40.

[0046] Heat treatment of CIGS precursor film: In 100000Pa nitrogen, heat the solid elemental Se source to 180°C to form the saturated vapor pressure of Se, place the CIGS precursor film in the saturated Se vapor pressure, and heat the CIGS at a heating rate of 10°C / min. The precursor film is heated to 450° C. and kept for 60 minutes to prepare the desired CIGS light-absorbing layer.

Embodiment 3

[0048] Preparation of CIGS precursor film: on molybdenum-coated stainless steel foil, with Cu 0.5 In 0.3 Ga 0.7 Se 1.75 As a target, the CIGS precursor film was prepared by radio frequency sputtering, and the sputtering power density was 3.0Wcm -2 , the target distance is 10cm, the working pressure is 5Pa; the thickness of the prepared CIGS precursor film is 1500nm, due to the difference of element sputtering rate, in the prepared CIGS precursor film, Cu / (In+Ga)=0.49, Ga / ( In+Ga) = 0.70.

[0049] Heat treatment of CIGS precursor film: In 10000Pa nitrogen, heat the solid elemental Se source to 350°C to form the saturated vapor pressure of Se, place the CIGS precursor film in the saturated Se vapor pressure, and heat the CIGS at a heating rate of 50°C / min. The precursor film is heated to 500° C. and kept for 30 minutes to prepare the desired CIGS light-absorbing layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com