Macromolecular microballoon sphere silver-carrying antibiotic finishing agent and preparation method thereof

A polymer microsphere, silver-loaded antibacterial technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of poor heat resistance, high cost, short duration of drug effect, etc., to achieve increased durability and longer-lasting antibacterial , to avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

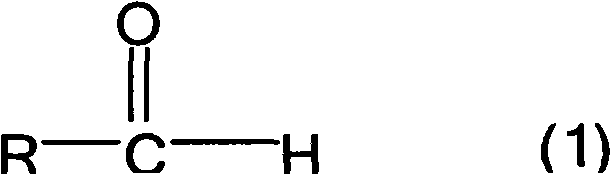

[0033] A polymer microsphere silver-loaded antibacterial finishing agent is made by reacting polymer microsphere dispersion liquid with carboxyl groups on the surface, silver ammonia solution and reducing agent, wherein 60 parts of polymer microsphere dispersion liquid with carboxyl groups on the surface, Silver ammonia solution 15 parts, reducing agent 5 parts. Wherein, the reducing agent is acetaldehyde.

[0034] The preparation method of the above-mentioned polymer microsphere-loaded silver antibacterial finishing agent comprises the following steps:

[0035] First, slowly add the dispersion of polymer microspheres with carboxyl groups on the surface into the container containing the silver ammonia solution, and stir evenly, then add the reducing agent into the container, and use the silver mirror to react. Stirring and reacting for 2 hours, the polymer microsphere-loaded silver antibacterial finishing agent is obtained.

[0036] The polymer microsphere dispersion with ca...

Embodiment 2

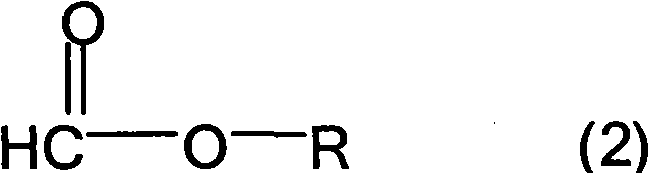

[0042] A polymer microsphere silver-loaded antibacterial finishing agent is made by reacting polymer microsphere dispersion liquid with carboxyl groups on the surface, silver ammonia solution and reducing agent, wherein 75 parts of polymer microsphere dispersion liquid with carboxyl groups on the surface, Silver ammonia solution 20 parts, reducing agent 10 parts. Wherein, the reducing agent is ethyl formate.

[0043] The preparation method of the above-mentioned polymer microsphere-loaded silver antibacterial finishing agent comprises the following steps:

[0044] First, slowly add the dispersion of polymer microspheres with carboxyl groups on the surface into the container containing the silver ammonia solution, and stir evenly, then add the reducing agent into the container, and use the silver mirror to react. After stirring and reacting for 1.8 hours, the polymer microsphere-loaded silver antibacterial finishing agent was obtained.

[0045] The polymer microsphere dispers...

Embodiment 3

[0051] A polymer microsphere silver-loaded antibacterial finishing agent is made by reacting polymer microsphere dispersion liquid with carboxyl groups on the surface, silver ammonia solution and reducing agent, wherein 90 parts of polymer microsphere dispersion liquid with carboxyl groups on the surface, Silver ammonia solution 30 parts, reducing agent 15 parts. Among them, the reducing agent is glucose.

[0052] The preparation method of the above-mentioned polymer microsphere-loaded silver antibacterial finishing agent comprises the following steps:

[0053] First, slowly add the dispersion of polymer microspheres with carboxyl groups on the surface into the container containing the silver ammonia solution, and stir evenly, then add the reducing agent into the container, and use the silver mirror to react. After stirring and reacting for 1.5 hours, the polymer microsphere-loaded silver antibacterial finishing agent was obtained.

[0054] The polymer microsphere dispersion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com