Micro-emulsion clean fuel and preparation method thereof

A clean fuel and microemulsion technology, applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of white floc precipitation, easy emulsion breaking, etc., achieve simple process, reduce dependence, and improve environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

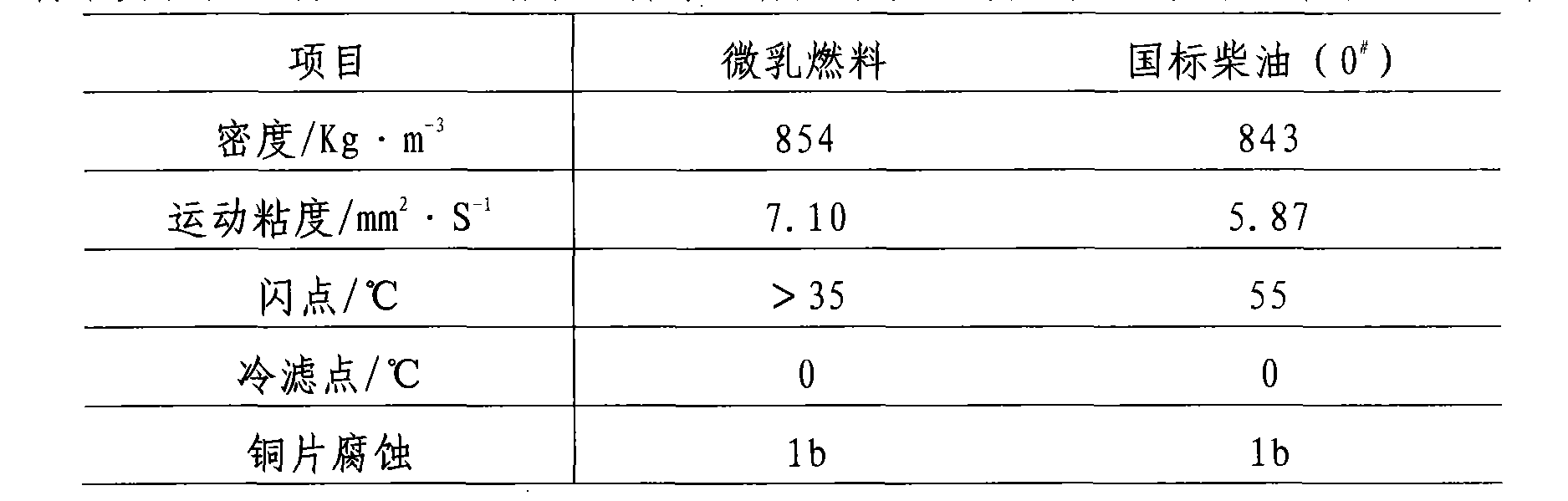

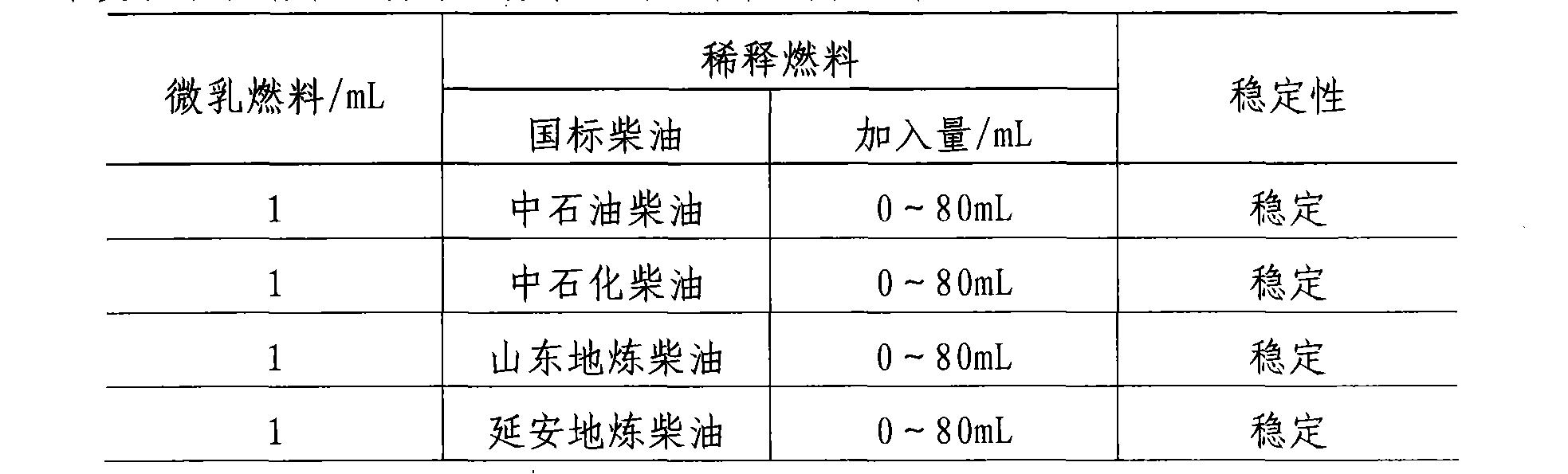

Examples

Embodiment 1

[0025] The raw material mass percent of microemulsion clean fuel is:

[0026] Diesel 80

[0027] Fatty acid (freezing point 11~14℃) 8

[0028] Tetradecylamine 1.6

[0029] Ammonia (25~27%) 2

[0030] water 8.4

[0031] Add diesel oil, fatty acid, and tetradecylamine into the stirring tank, stir and dissolve at 20°C, add water and stir for 10 minutes, add ammonia water dropwise, continue stirring for 15 minutes, heat to 40°C, stir and cool to ambient temperature, and pack into barrels for use.

Embodiment 2

[0033] The raw material mass percent of microemulsion clean fuel is:

[0034] Diesel 80

[0035] Fatty acid (freezing point 18~22℃) 7.8

[0036] tetradecyl dimethyl tertiary amine 1.5

[0037] Ammonia (25~27%) 1.9

[0038] water 8

[0039] Ethanol 0.8

[0040] Add diesel oil, fatty acid, tetradecyl dimethyl tertiary amine into the stirring tank, stir and fully dissolve at 25°C, add water and ethanol, stir for 10 minutes, add ammonia water dropwise, continue stirring for 15 minutes, put into barrels and wait use.

Embodiment 3

[0042] The raw material mass percent of microemulsion clean fuel is:

[0043] Diesel 80

[0044] Fatty acid (freezing point 16~19℃) 8.1

[0045] Diethylamine 0.6

[0046] Ammonia (25~27%) 1.9

[0047] water 9

[0048] Methanol 0.4

[0049] Add diesel oil, fatty acid, and diethylamine into the stirring tank, stir and dissolve at 30°C, add water and methanol, stir for 10 minutes, add ammonia water dropwise, continue stirring for 15 minutes, and put into barrels for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com