MEMS presser sensor chip and manufacturing method thereof

A technology of sensitive chip and pressure, applied in the direction of fluid pressure measurement, manufacturing tools, and manufacturing microstructure devices by changing ohmic resistance, which can solve the problem of long photosensitive effect and hysteresis effect in the electrical connection part of the varistor, and the stress concentration of the varistor. It can solve the problems of low sensitivity and low linearity of the chip, so as to increase the effective bonding area, concentrate the stress area, and improve the sensitivity and linearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

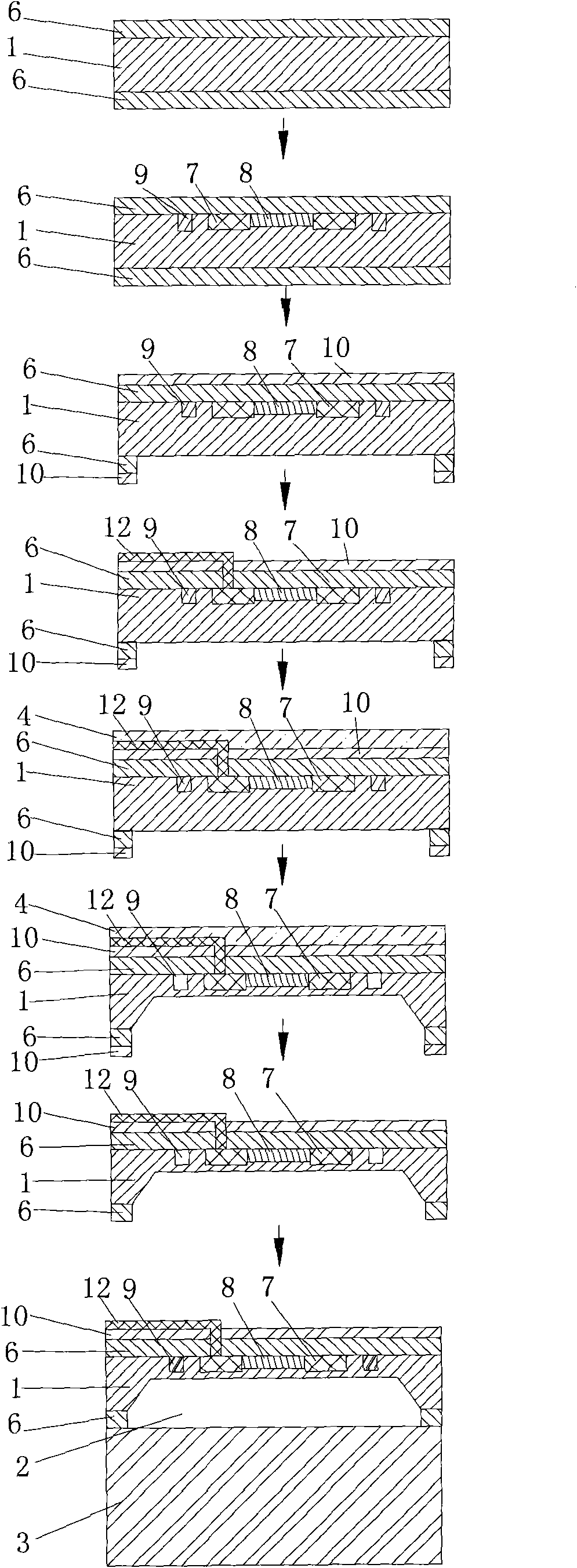

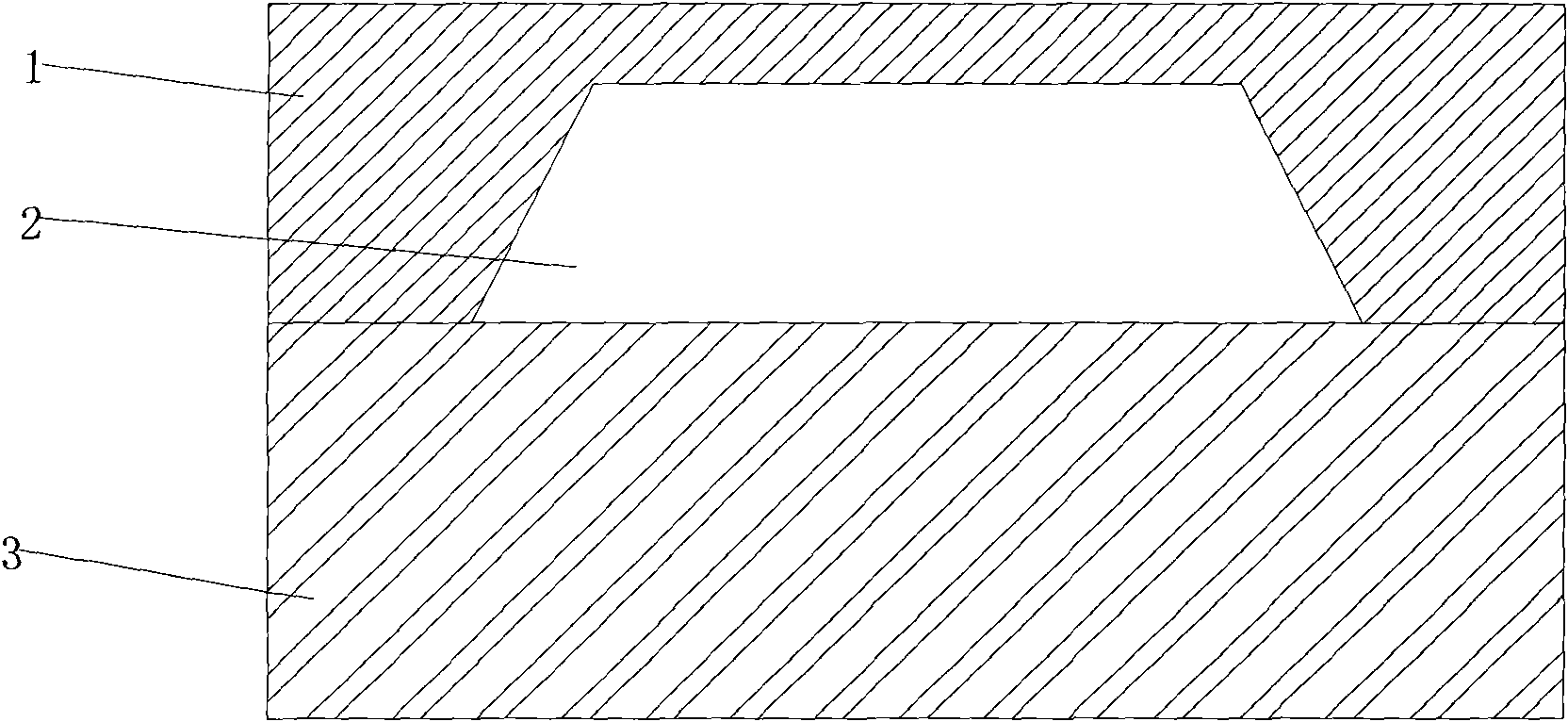

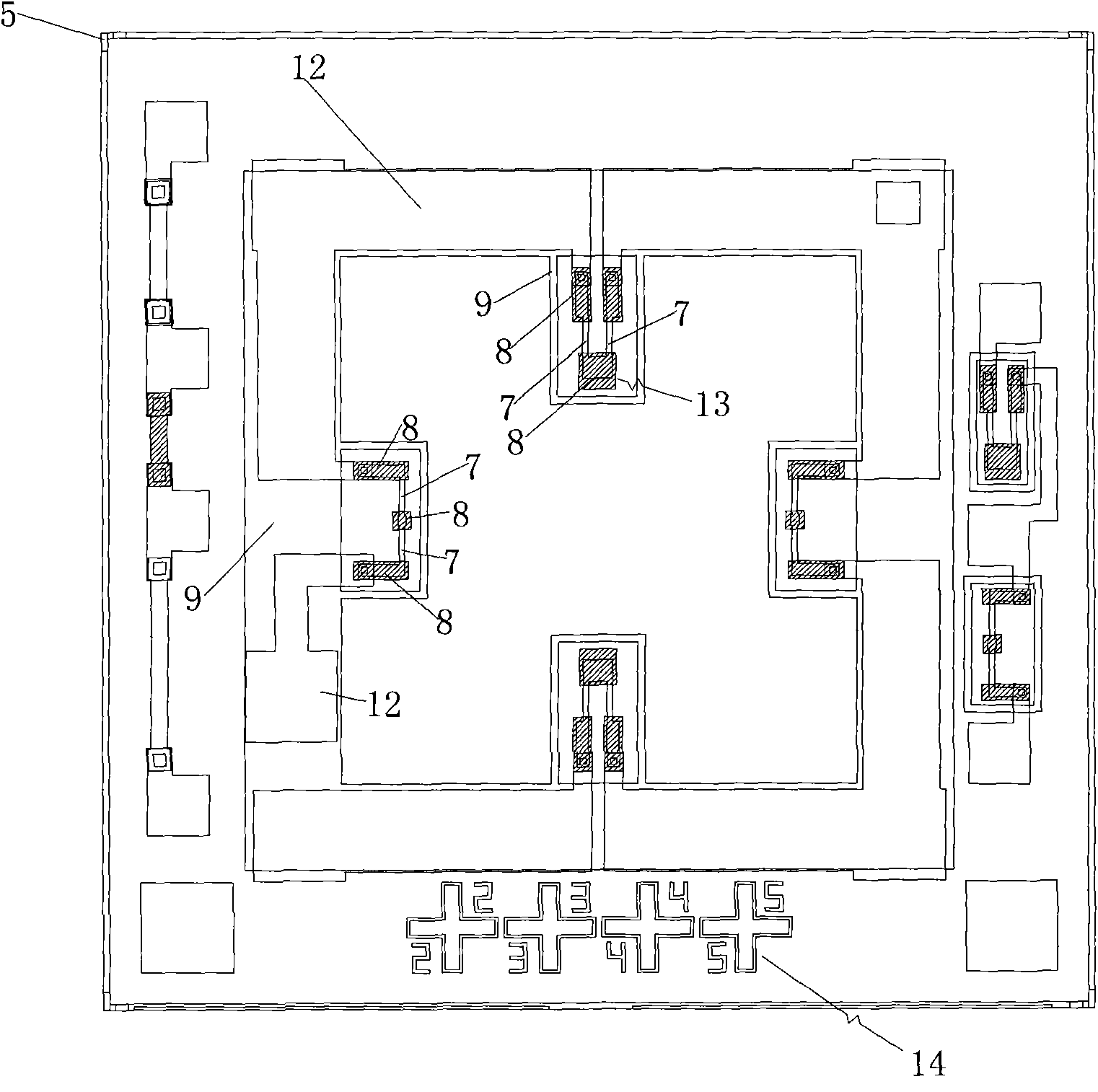

[0029] For the chip structure of the present invention, see figure 2 , image 3 , Which includes a silicon wafer 1, a vacuum chamber 2, a glass substrate 3, a sensitive resistor arrangement area, an external electrical connection member of the sensitive resistor arrangement area, and an alignment mark assembly 14. The four corners of the silicon wafer 1 are respectively provided with alignment marks Structure 5, the maximum stress linear area on the front side of silicon wafer 1 is the sensitive resistor arrangement area, the shape of the sensitive resistor arrangement area is rectangular, and the sensitive resistor arrangement area includes varistor, P + Connection 8, N + Isolation groove 9, aluminum electrode 12, the varistor is specifically two pairs of bridge resistors 13, each of which includes a pair of sensitive resistors 7, which is specifically a linear resistor, and the bridge resistors 13 of each pair of bridge resistors are arranged symmetrically. Arranged on the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com