Micro molecular white-light organic light-emitting device produced by wet method

An electroluminescent device and small molecule technology, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of low purity and low performance of polymer materials, and achieve high cost and stable white light emission in the evaporation process , the effect of easy large-area preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] (3) Preparation of each organic functional layer: put the spin-coated and dried substrate into the vacuum chamber, and sequentially evaporate the hole blocking material to form the hole blocking layer 4. The evaporation rate of the material film 0.01-0.5nm / s, the film thickness is 10-40nm; the organic electron-transporting layer 5 is formed by evaporating an organic electron-transporting material on the hole-blocking layer, the evaporation rate is 0.01-0.5nm / s, and the film thickness is 30-40nm. 40nm.

[0037] (4) Preparation of the cathode 6: keep the pressure in the vacuum chamber constant, and vapor-deposit the LiF / Al composite cathode on the electron transport layer 5 above.

Embodiment 1

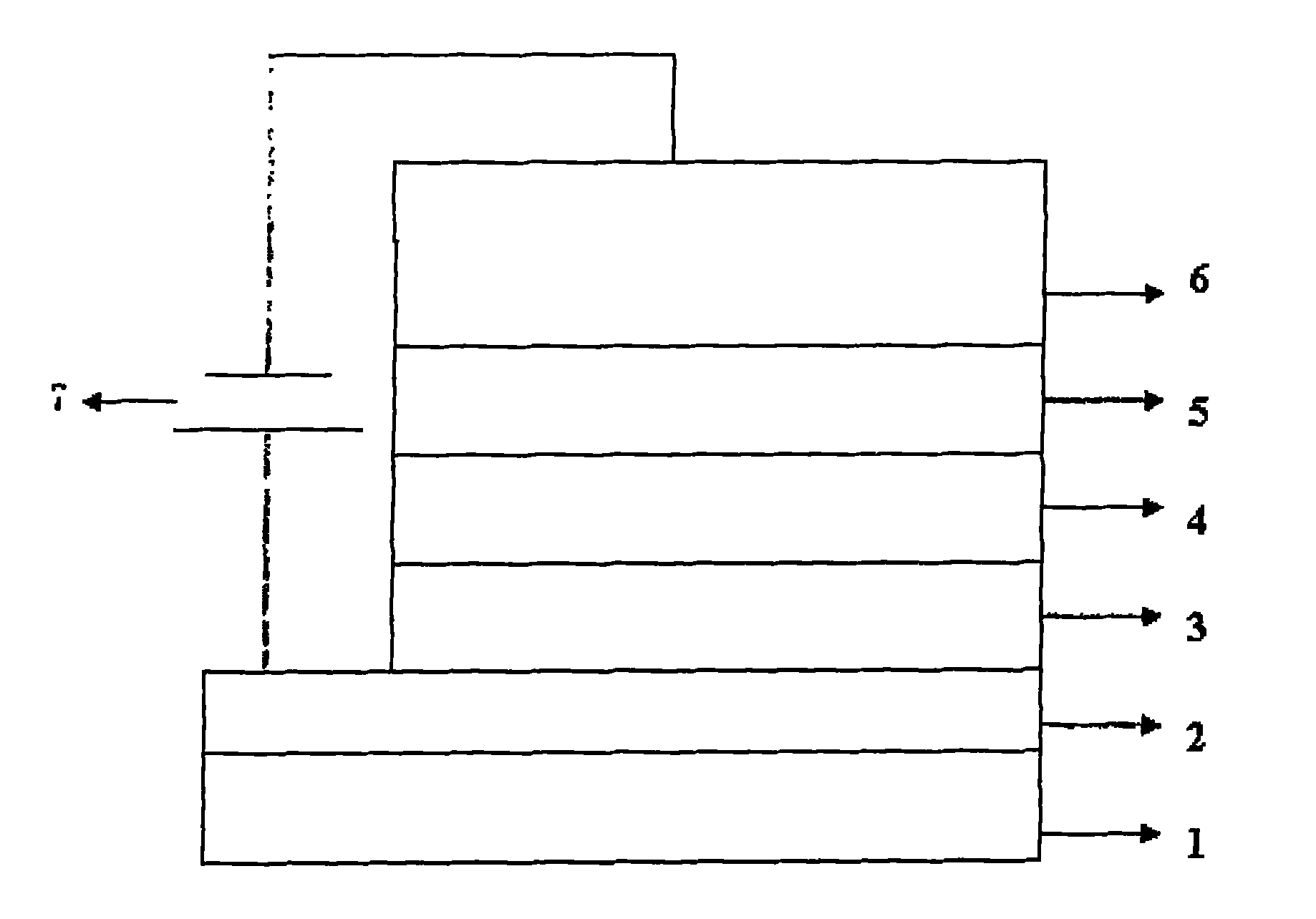

[0039] now refer to figure 1 , the electroluminescent device according to the first embodiment of the present invention has the following structure:

[0040]Glass (plastic) substrate / ITO(100nm) / NPB:DPVBi(15wt%):DPAVBi(4%):Rubrene(0.3%)(50nm) / BCP(10nm) / Alq 3 (30nm) / LiF(0.6nm) / Al(80nm)

[0041] (1) Cleaning of glass substrates pre-engraved with ITO: use hot detergent ultrasonic and deionized water ultrasonic methods to clean the transparent conductive substrate ITO glass, and place it under an infrared lamp to dry after cleaning. The ITO film on the substrate is used as the anode layer of the device. The sheet resistance of the ITO film is 5Ω~100Ω, and the film thickness is 80~280nm.

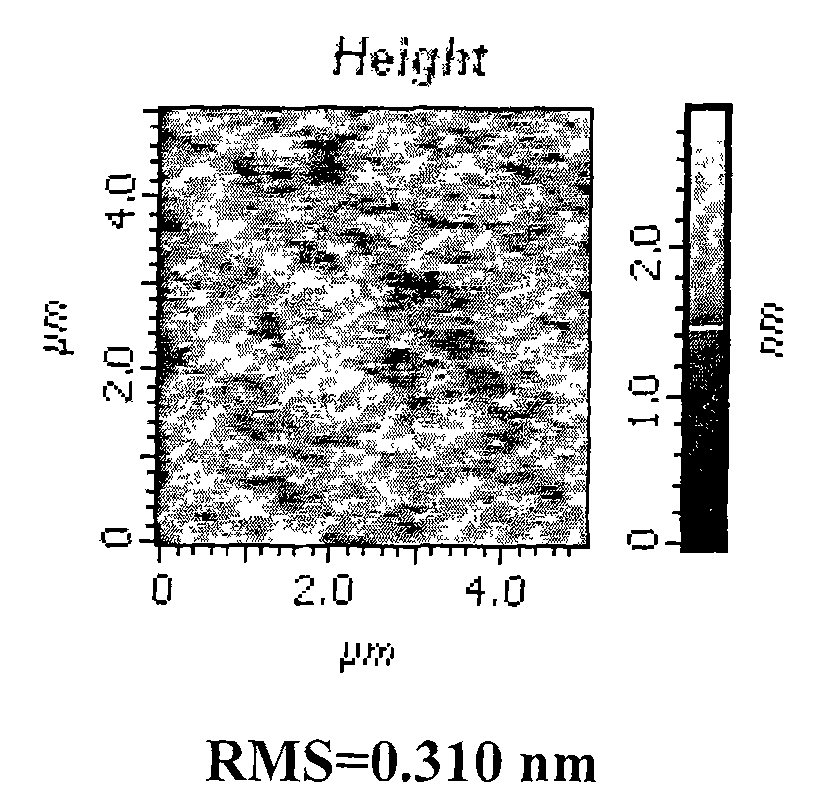

[0042] (2) White light emitting layer: Place the above-mentioned cleaned and dried ITO glass on a KW-4A glue homogenizer, spin-coat the configured mixed solution to form a film by static batching method, and the speed of the glue homogenizer is 1000rpm, The time is controlled at 40s; the sample...

Embodiment 2

[0049] now refer to figure 1 , the electroluminescent device according to the second embodiment of the present invention has the following structure:

[0050] Glass (plastic) substrate / ITO(100nm) / NPB:MADN(15wt%):DPAVBi(5%):Rubrene(0.3%)(50nm) / BCP(10nm) / Alq 3 (30nm) / LiF(0.6nm) / Al(80nm)

[0051] (1) The cleaning of the glass substrate that is engraved with ITO in advance: refer to the corresponding process of embodiment 1;

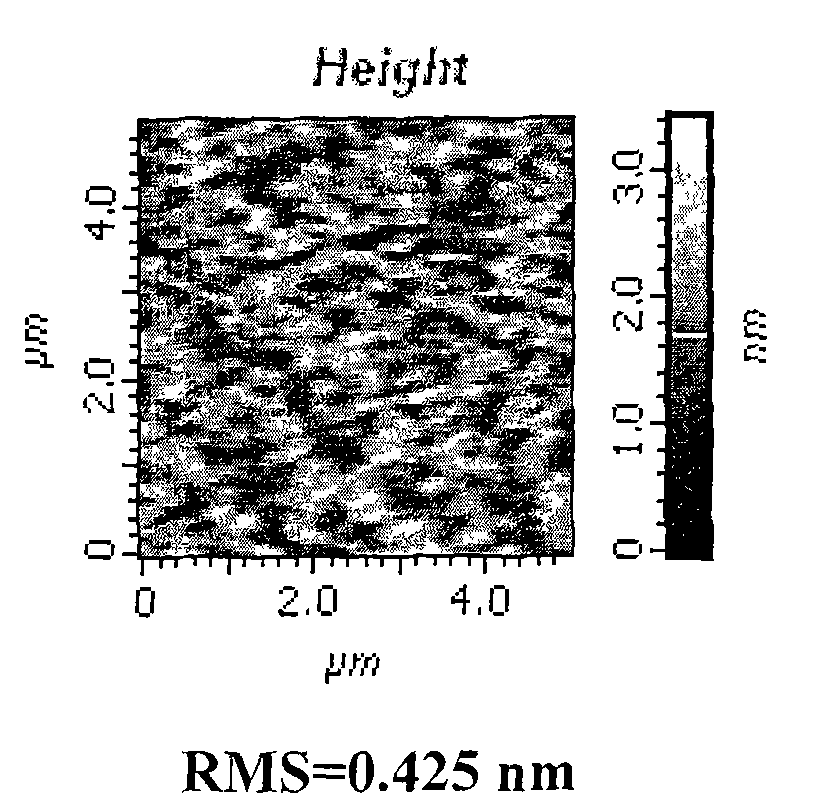

[0052] (2) Mixed white light emitting layer: the optimized ratio of MADN is 15wt%, the optimized doping concentration of blue light dye is 5wt%, and the concentration of yellow light dye is 0.3wt%. The solvent is chlorobenzene, and the spin-coating and drying conditions refer to the corresponding process of Example 1; Figure 2(b) is an AFM image of the surface morphology of the spin-coated organic small molecule hole injection layer, RMS=0.425nm.

[0053] (3) Preparation of each organic functional layer: refer to the corresponding process of Example 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com