Preparation method of lanthanum oxide-carrying zeolite for removing fluorine

A technology of lanthanum oxide and zeolite, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., to achieve the effects of good fluorine removal ability, simple and easy regeneration method, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

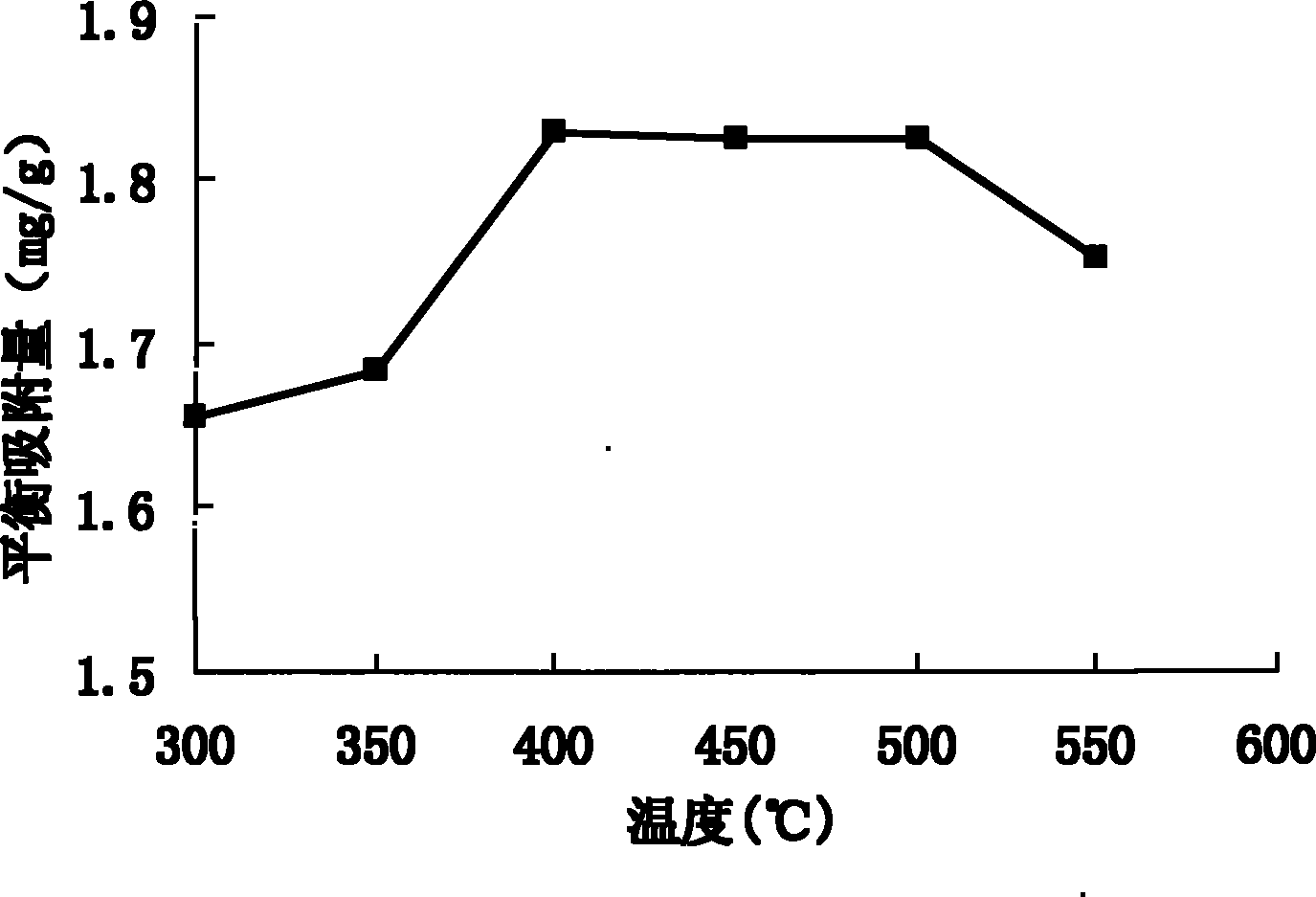

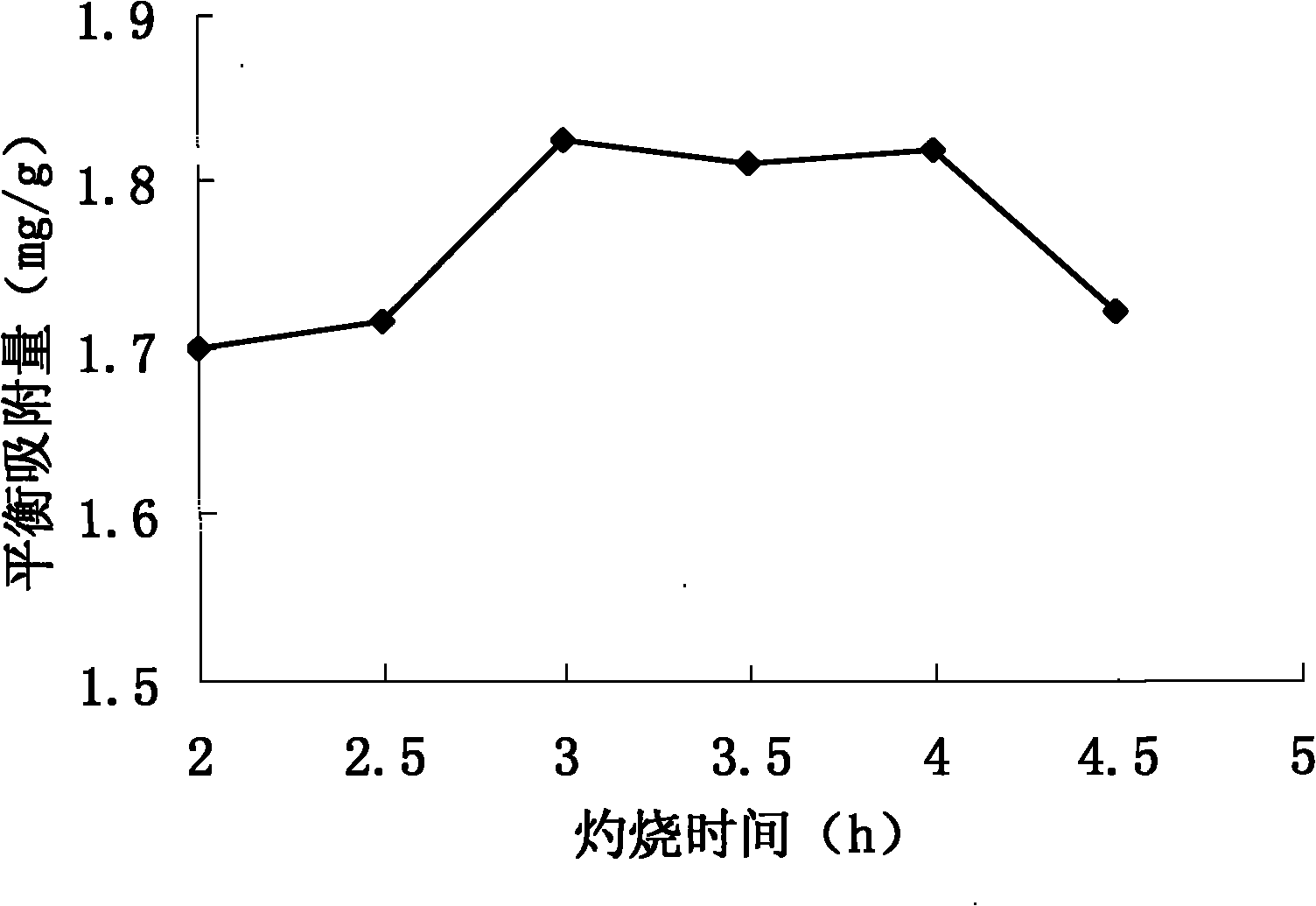

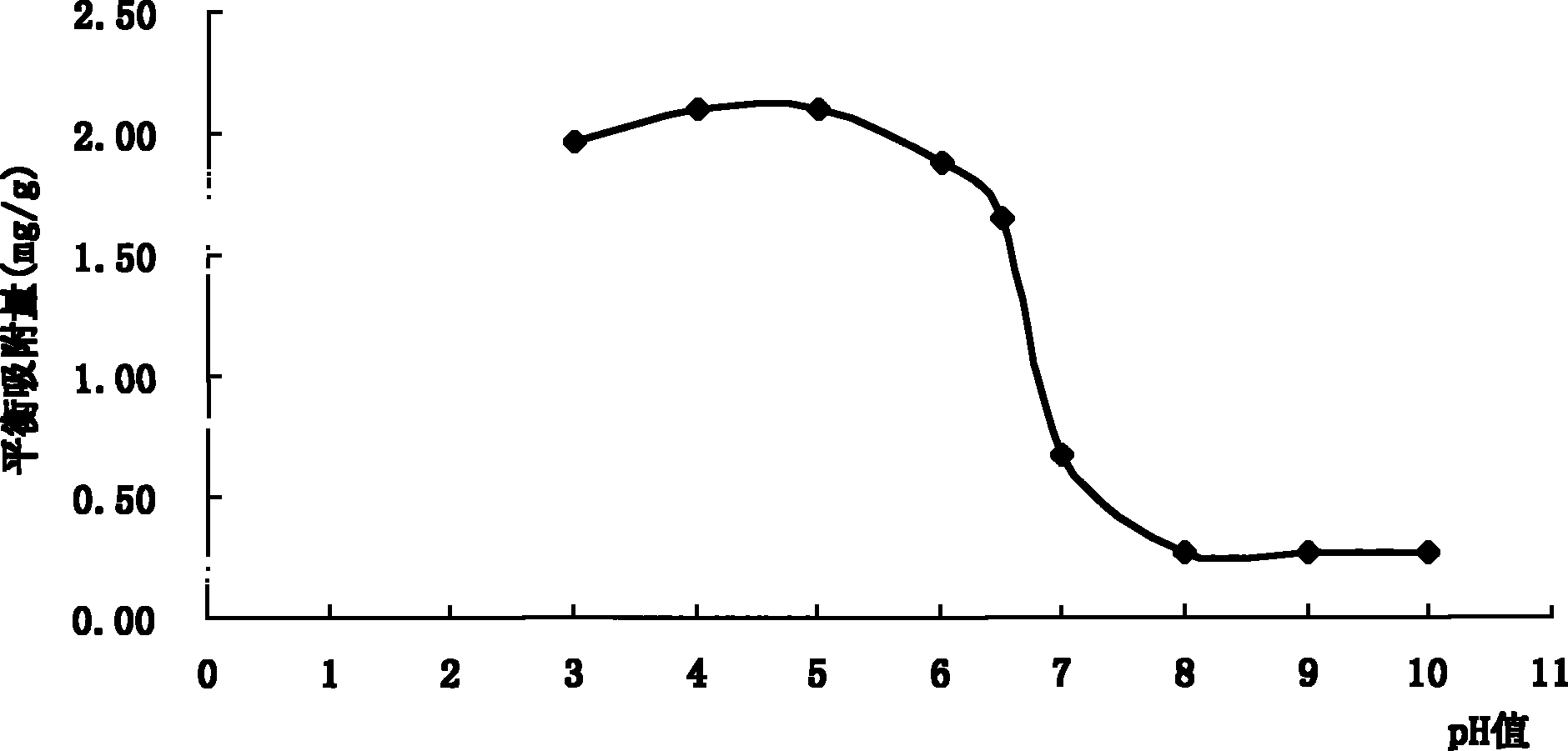

[0051] Example 1 Preparation experiment of loaded lanthanum oxide zeolite

[0052] 1. Take a certain amount of pretreated zeolite in an Erlenmeyer flask, add a certain concentration of lanthanum chloride solution with a solid-to-liquid ratio of 1:5 (zeolite g: modifier solution volume ml), adjust with 28wt% concentrated ammonia water When the pH is 11-12, cover the cork immediately, impregnate and stir it for 24 hours at room temperature, discard the filtrate and dry it, then put it in a muffle furnace and burn it at high temperature for a certain period of time, take it out and wash the residual lanthanum ion with distilled water after cooling, 80 ℃ drying. The effects of different pretreatment methods of zeolite, modifier concentration, igniting temperature, igniting time and other experimental conditions on the modified zeolite were investigated, and the preparation conditions of the modified zeolite were optimized.

[0053] 2. Take 25g of zeolite and soak it in 125ml of 2...

Embodiment 2

[0057] The pretreatment of embodiment 2 loaded lanthanum oxide zeolite

[0058] Acid treatment method: soak the zeolite in 0.5mol / L hydrochloric acid for 2 hours, then wash it with distilled water until neutral.

[0059] Alkali treatment method: soak the zeolite in 2wt% sodium hydroxide for 2 hours, then wash it with distilled water until neutral.

[0060] The acid-base pretreated zeolite and the original zeolite were modified according to the preparation method of the lanthanum oxide-loaded zeolite in Example 1. Take 2.0g of zeolite each and pack it into a column, and conduct a dynamic defluorination test through the column. The results are shown in Table 1.

[0061] Table 1 Dynamic defluorination results of modified zeolite with different pretreatment methods

[0062]

[0063] The results in Table 1 show that the best dynamic defluoridation effect is the lanthanum oxide zeolite loaded after alkali treatment, followed by the directly loaded lanthanum oxide zeolite. Sin...

Embodiment 3

[0064] The selection of embodiment 3 lanthanum chloride concentration

[0065] After the zeolite was pretreated by alkali, it was soaked and modified with lanthanum chloride solution of 2wt%, 5wt%, 10wt%, 15wt%, and 20wt%, respectively, and 2.0g of modified zeolite was packed into a column for dynamic defluorination test. See Table 2.

[0066] Table 2 Dynamic defluorination results of lanthanum chloride modified zeolite with different concentrations

[0067]

[0068] According to Table 2, the effective fluoride removal capacity increases with the increase of lanthanum chloride concentration. When the concentration is 2-10wt%, the fluorine removal capacity does not increase significantly, and when it reaches 15wt%, the fluoride removal capacity increases obviously, and the concentration of lanthanum chloride does not change significantly when the concentration is 15wt% to 20wt%, so the selected concentration is 15wt% chlorine Lanthanum chloride solution for zeolite modific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com