Preparation method of corn protein nano-particles

A technology of zein and nanoparticles, which is applied in the field of preparation of zein nanoparticles, can solve problems such as adverse reactions and reduce the frequency of medication, and achieve the effects of reducing drug side effects, increasing residence time, and narrow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 300 mg of zein was dissolved in 15 ml of a mixed solvent of acetone and dimethyl sulfoxide at a volume ratio of 7:3 to prepare a 20 mg / ml zein solution. Pump carbon dioxide into the autoclave. After the autoclave reaches the preset temperature of 40°C and pressure of 10MPa and stabilizes for 5 minutes, pump the zein solution at a flow rate of 1.0ml / min. After the solution is pumped, continue to feed carbon dioxide for 30 minutes, stop feeding carbon dioxide, release the pressure, and collect the particles in the reaction kettle to obtain zein nanoparticles.

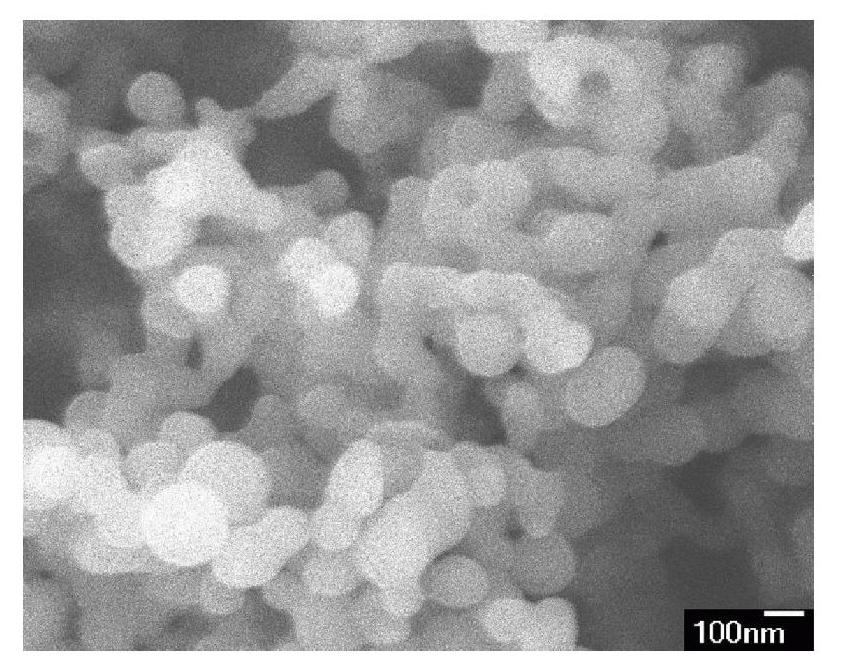

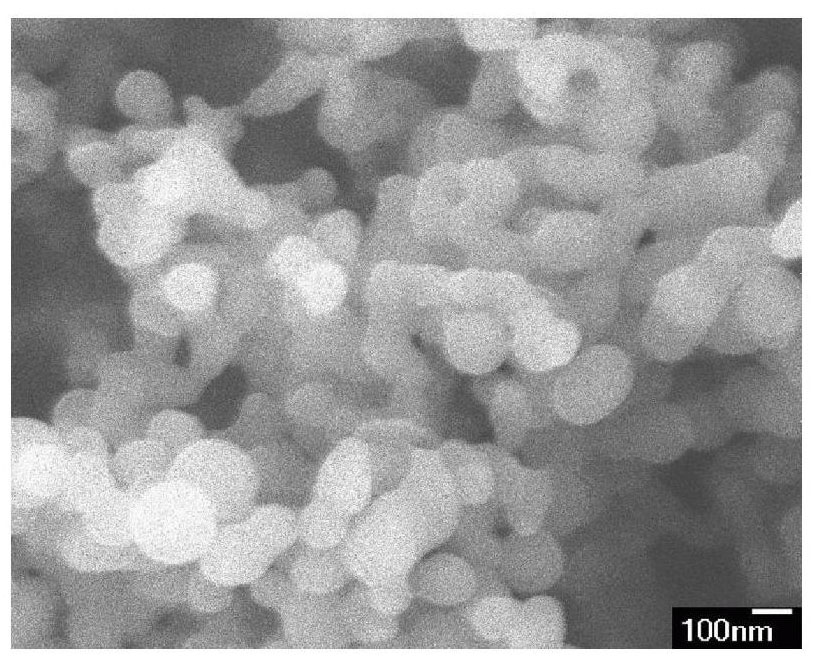

[0026] The morphology of the prepared zein nanoparticles was observed with a field emission scanning electron microscope. Stick the solid powder directly on the conductive glue and spray gold under vacuum state to observe. The result is as figure 1 shown.

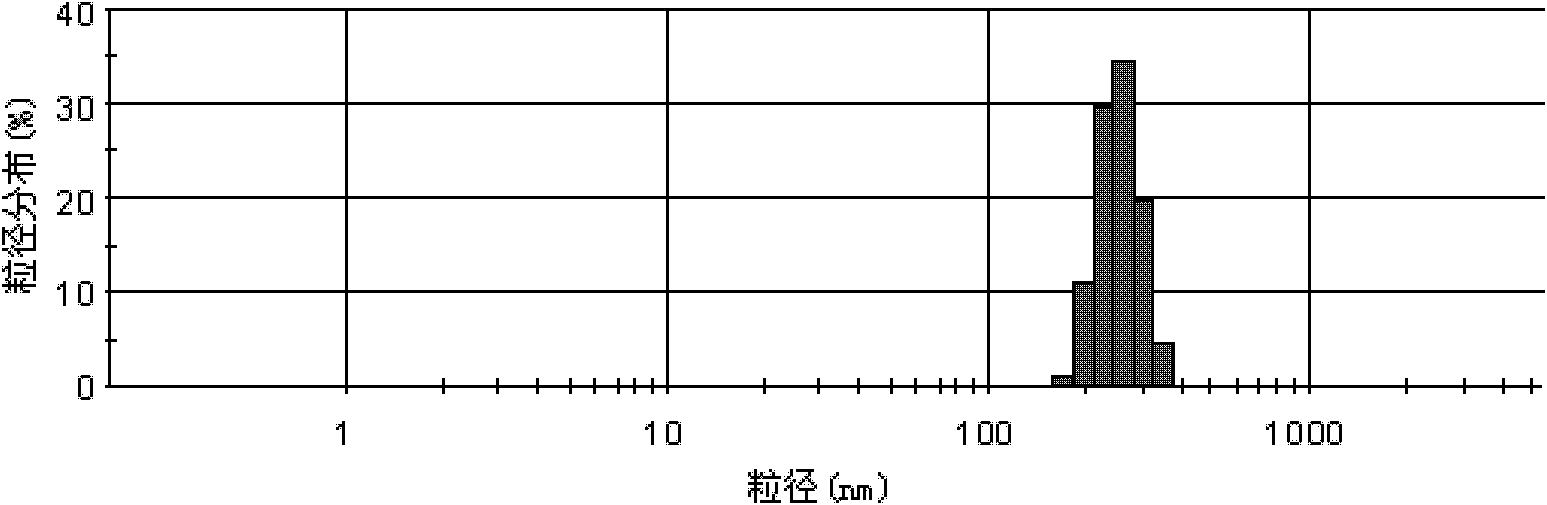

[0027] The prepared zein nanoparticles were tested for particle size and distribution with a nanoparticle size analyzer, and the sample to be tested was disp...

Embodiment 2

[0029] 150 mg of zein was dissolved in 15 ml of mixed solvent of acetone and dimethyl sulfoxide at a volume ratio of 7:3 to prepare a 10 mg / ml zein solution. Pump carbon dioxide into the autoclave. After the autoclave reaches the preset temperature of 40°C and pressure of 10MPa and stabilizes for 5 minutes, pump the zein solution at a flow rate of 1.0ml / min. After the solution is pumped, continue to feed carbon dioxide for 30 minutes, stop feeding carbon dioxide, release the pressure, and collect the particles in the reaction kettle to obtain zein nanoparticles.

[0030] The particle size and distribution detection of zein nanoparticles are the same as in Example 1, the particle size distribution is between 110nm-300nm, and the average particle size is 217nm.

Embodiment 3

[0032] 300 mg of zein was dissolved in 15 ml of a mixed solvent of acetone and dimethyl sulfoxide at a volume ratio of 7:3 to prepare a 20 mg / ml zein solution. Pump carbon dioxide into the autoclave. After the autoclave reaches the preset temperature of 32°C and pressure of 10MPa and stabilizes for 5 minutes, pump the zein solution at a flow rate of 1.0ml / min. After the solution is pumped, continue to feed carbon dioxide for 30 minutes, stop feeding carbon dioxide, release the pressure, and collect the particles in the reaction kettle to obtain zein nanoparticles.

[0033] The particle size and distribution detection of zein nanoparticles are the same as in Example 1, the particle size distribution is between 105nm-280nm, and the average particle size is 197nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com