Antifouling flash insulator coating and preparation method thereof

An insulator, anti-pollution flashover technology, applied in anti-fouling/underwater coatings, insulators, coatings, etc., can solve the problems of electrical performance, anti-pollution, anti-aging performance, and inability to obtain target products, and achieve anti-pollution flashover. Strong anti-fouling performance, strong anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

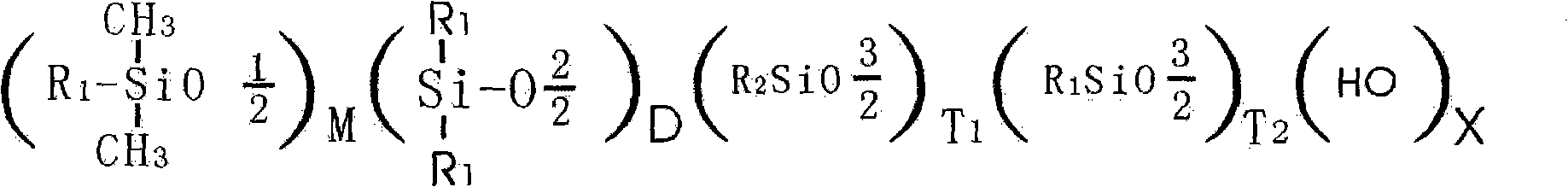

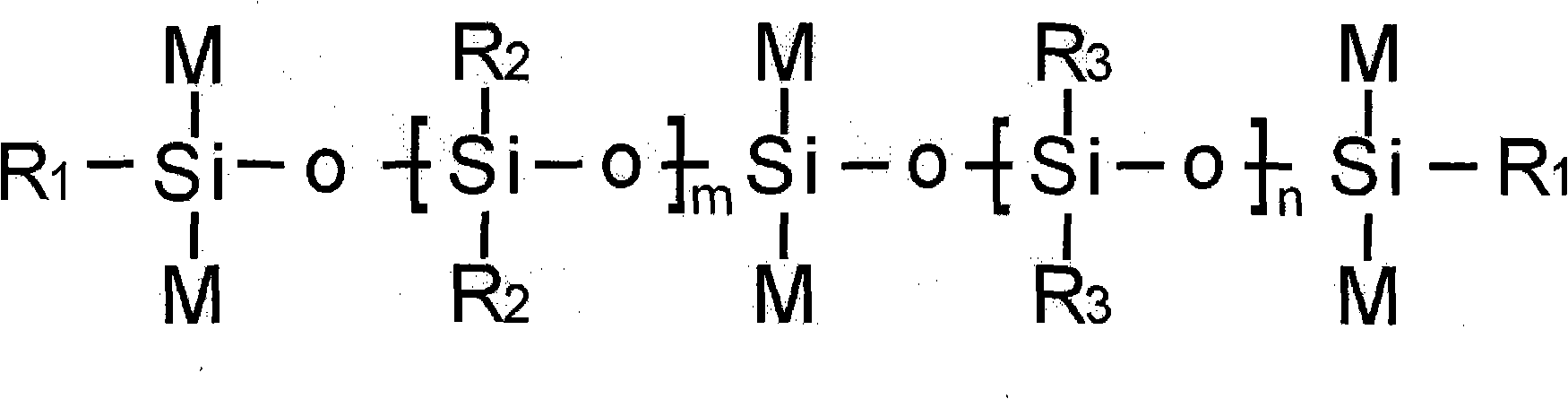

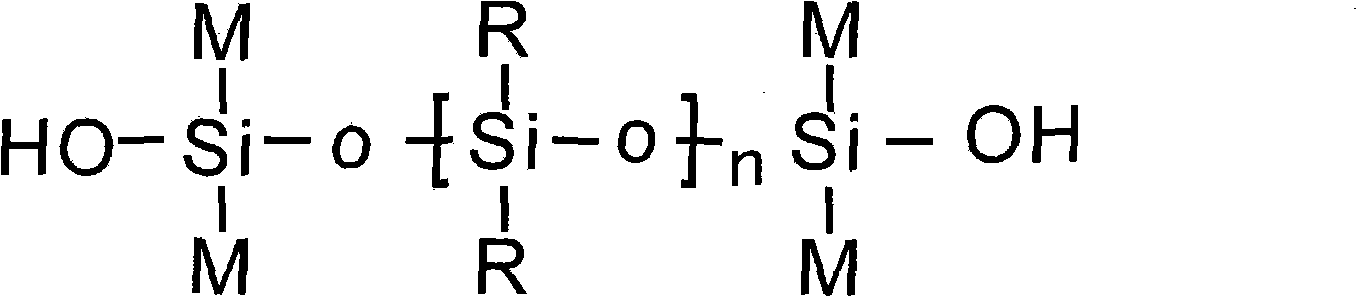

[0049] Synthetic components

[0050] Synthesis of Component A

[0051] 1. Synthesis of A1 fluorine-containing silicone resin polysiloxane

[0052] In the flask, add 36.4 grams of methylphenyldimethoxysilane, 280.8 grams of tridecafluorooctyltrimethoxysilane, 81.6 grams of methyltrimethoxysilane, 34.1 grams of dimethylphenylchlorosilane and 310 grams of toluene Stir and mix, add 72 grams of water dropwise over 1 hour, and the dropwise addition is complete. After stirring for 30 minutes, the temperature was raised to reflux for 1 hour, 300 grams of toluene and 250 grams of water were added and the mixture was stirred and separated. The aqueous acid layer was removed, and the organic layer was neutralized with NaHCO3, dried with anhydrous sulfuric acid and filtered.

[0053] Alcohol and solvent were distilled off under normal pressure to obtain a mixture of toluene and fluorosilicone resin with a solid content of 50%. Colorless and transparent, the HO-(hydroxyl) content is ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com