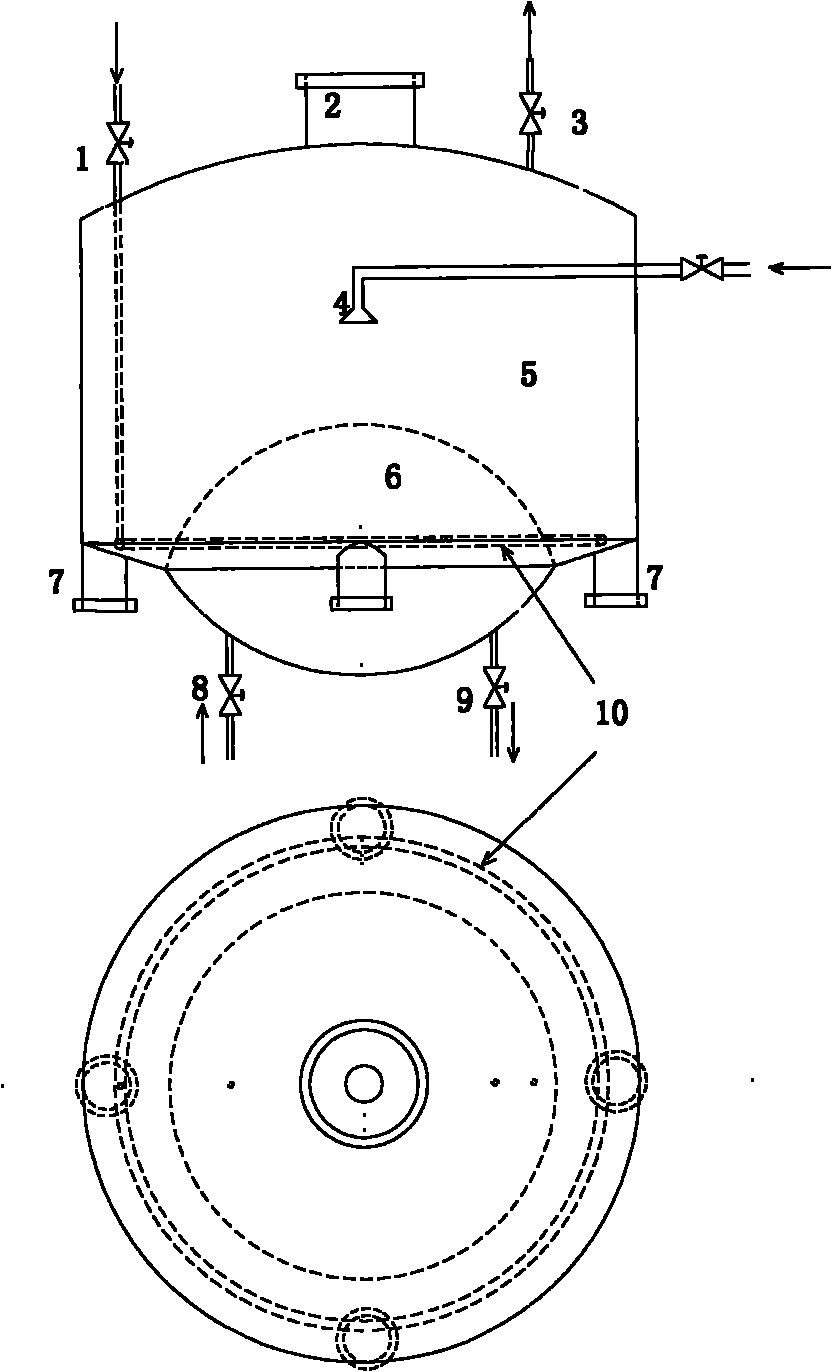

Air bag agitation-type solid-state fermentation method and device thereof

A solid-state fermentation and air bag technology, which is applied in the field of fermentation industry, can solve the problems of difficult amplification and heat transfer, and achieve the effects of wide application range, small shear force, and small mycelium damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Example 1: Production of ethanol by solid-state fermentation of sweet sorghum

[0026] Preparation of materials: remove ears, leaves and roots from the sweet sorghum stalks harvested after maturity, and use a straw crusher to crush them;

[0027] Loading: the pulverized sweet sorghum is loaded into the fermentation tank from the feed port, and the charging coefficient is 50% of the volume of the fermentation tank.

[0028] Sterilization: Pass high-temperature steam through the air inlet (1) of the fermenter to sterilize. The sterilization temperature is 121-125°C, and the sterilization time is 15-20min.

[0029] Inoculation: Mix active dry yeast (Angel Yeast) with sterile water, the mixing ratio is 1g of yeast plus 40mL of sterile water, activate at 35°C for 25-30min, and then place it at room temperature for 45-60min after activation; Add 20ml of activation solution to mix sweet sorghum with activation solution;

[0030] Fermentation: Maintain the ambient temperatur...

example 2

[0032] Example 2: Production of cellulase by solid-state fermentation of steam-exploded wheat straw

[0033] Preparation of materials: The harvested wheat straw is steam-exploded and air-dried for later use.

[0034] Filling: the dry steam-exploded wheat straw and water are mixed and stirred evenly according to the mass ratio of 1:5, and filled into the fermentation tank, and the charging amount is 50% of the tank volume.

[0035] Sterilization: Pass high-temperature steam through the air inlet (1) of the fermenter to sterilize. The sterilization temperature is 121-125°C, and the sterilization time is 15-20min.

[0036] Inoculation: the green wood enzyme (Trichoderma viride) spores are blown into the solid-state fermentation tank with sterile air from the feed port (1) of the tank body, and the inoculum amount is 1g of green wood enzyme spores per tank.

[0037] Fermentation: Maintain the ambient temperature of the fermenter at about 30°C for fermentation. Blow in sterile a...

example 3

[0039] Example 3: Production of alkaline protease for steam-exploded wheat straw solid-state fermentation

[0040] Preparation of materials: Cut the cleaned polyurethane foam into square particles with a side length of 1 cm for later use. In addition, a liquid medium was prepared, and the ingredients were peptone 10g / L, beef extract 0.5g / L, and NaCl 0.5g / L.

[0041] Filling: Fill the above-mentioned dry polyurethane foam into the fermentation tank, and the charging amount is 50% of the tank volume.

[0042] Sterilization: Pass high-temperature steam through the air inlet (1) of the fermenter to sterilize. The sterilization temperature is 121-125°C, and the sterilization time is 15-20min. The medium was sterilized in a separate container at the same temperature and time.

[0043] Inoculation: Mix the suspension of Bacillus pumilus with a concentration of about 106 / ml with the sterilized and cooled medium at a volume ratio of 1:10, and spray it into the fermenter from the noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com