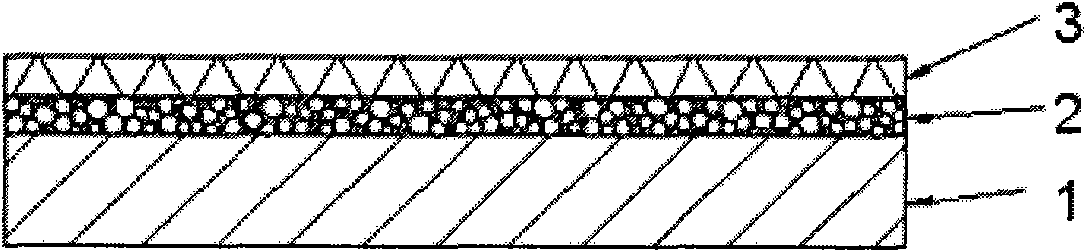

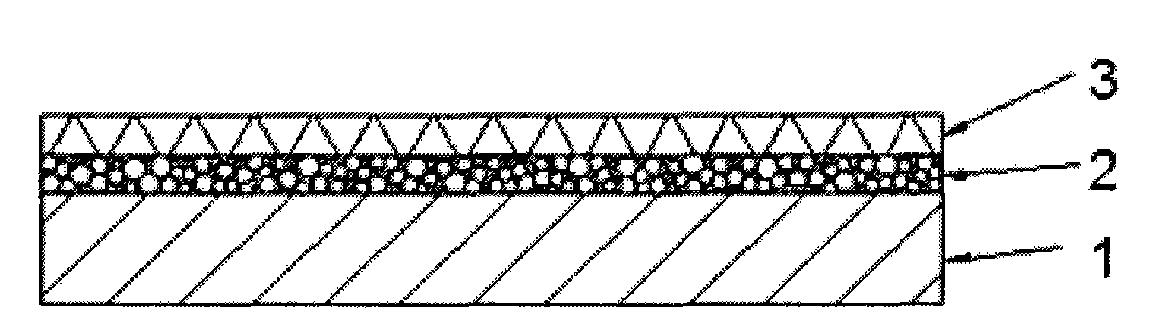

Three-layer self lubricating abrasion-resistant slide bearing material and preparation method thereof

A sliding bearing and self-lubricating technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of poor temperature resistance, high load capacity, low friction coefficient, etc. The effect of a low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

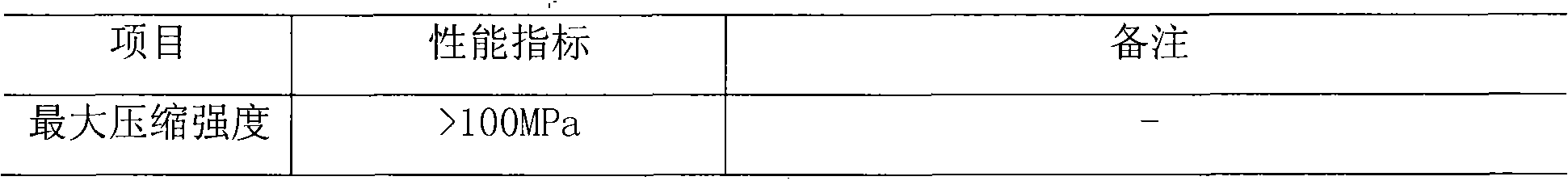

Embodiment 1

[0031] The clean plain weave Kevlar fabric is immersed in a 45% polytetrafluoroethylene emulsion for several minutes, taken out and dried at 105°C for 10 minutes, and repeated several times until the polytetrafluoroethylene volume fraction reaches 40%. Take another steel plate with tin bronze powder sintered on the surface, apply the above-mentioned PTFE with a brush to paint on the surface of the tin bronze layer, and dry at 105°C. Repeat this painting and drying several times until the PTFE is filled with the tin bronze layer. Pores. Lay the above Kevlar / PTFE composite material flat on the surface of the tin bronze layer impregnated with PTFE, pressurize it to 15MPa at 380°C, vent once every minute within 5 minutes, and keep the temperature and pressure for 15 minutes after 5 minutes , After holding pressure, natural cooling. The obtained material has a friction coefficient of 0.08 and a wear rate of 1.5×10 under a load of 25MPa -6 mm 3 / N·m.

Embodiment 2

[0033] Take the polytetrafluoroethylene emulsion with a mass fraction of 45%, add molybdenum disulfide to make the mass ratio of molybdenum disulfide and polytetrafluoroethylene 1:30, and stir thoroughly. Take the cleaned satin carbon fiber fabric, immerse it in it, take it out and dry it at 105°C for 10 minutes, repeat it several times until the volume fraction of the carbon fiber fabric is 50%. Take another steel plate with tin bronze powder sintered on the surface, apply the above-mentioned polytetrafluoroethylene to the surface of the tin bronze layer with a brush, dry at 105°C, and repeat several times until the polytetrafluoroethylene fills the pores of the tin bronze layer. Place the above-mentioned carbon fiber fabric / PTFE / molybdenum disulfide composite material flat on the surface of the tin bronze layer impregnated with PTFE, pressurize it to 12MPa at 380°C, vent once every minute within 5 minutes, and after 5 minutes Keep heat preservation and pressure for 15 minutes...

Embodiment 3

[0035] Take the clean plain weave carbon fiber fabric and immerse it in concentrated nitric acid for 2h, then wash it with deionized water until it is neutral and dry. Take the polytetrafluoroethylene emulsion with a mass fraction of 60%, immerse the carbon fiber fabric in it, take it out and dry it at 105°C for 10 minutes, and repeat it several times until the volume fraction of the carbon fiber fabric is 55%. Take another steel plate with tin bronze powder sintered on the surface, brush the surface of the tin bronze layer with the above-mentioned polytetrafluoroethylene with a brush, dry at 105°C, and repeat several times until the polytetrafluoroethylene fills the pores of the tin bronze layer. Place the above carbon fiber / PTFE composite material flat on the surface of the tin bronze layer impregnated with PTFE, pressurize to 12MPa at 380°C, deflate once every minute within 5 minutes, and keep the temperature and pressure for 15 minutes after 5 minutes , After holding pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com