Ferroelectric oxide/semiconductor composite film diode resistance change memory

A technology of ferroelectric oxide and resistive variable memory, which is applied in the field of microelectronics, can solve the problems of poor reliability of process integration and small number of times of erasing and writing, and achieve the effect of increasing the programming/erasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

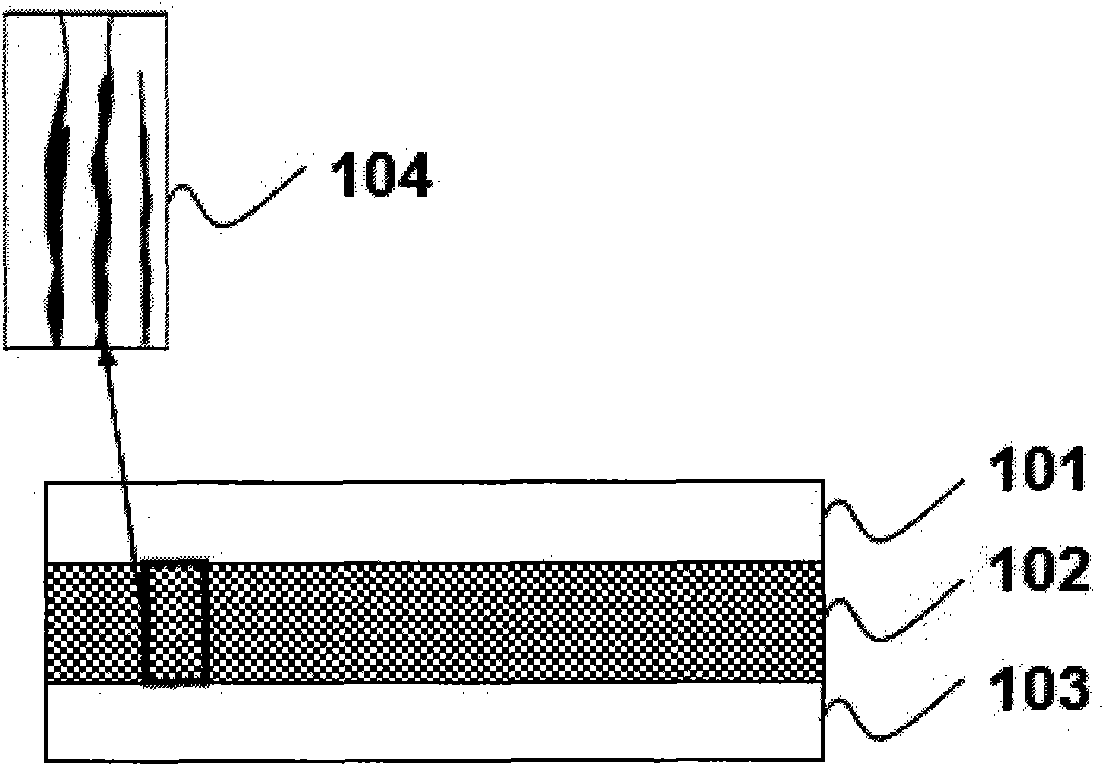

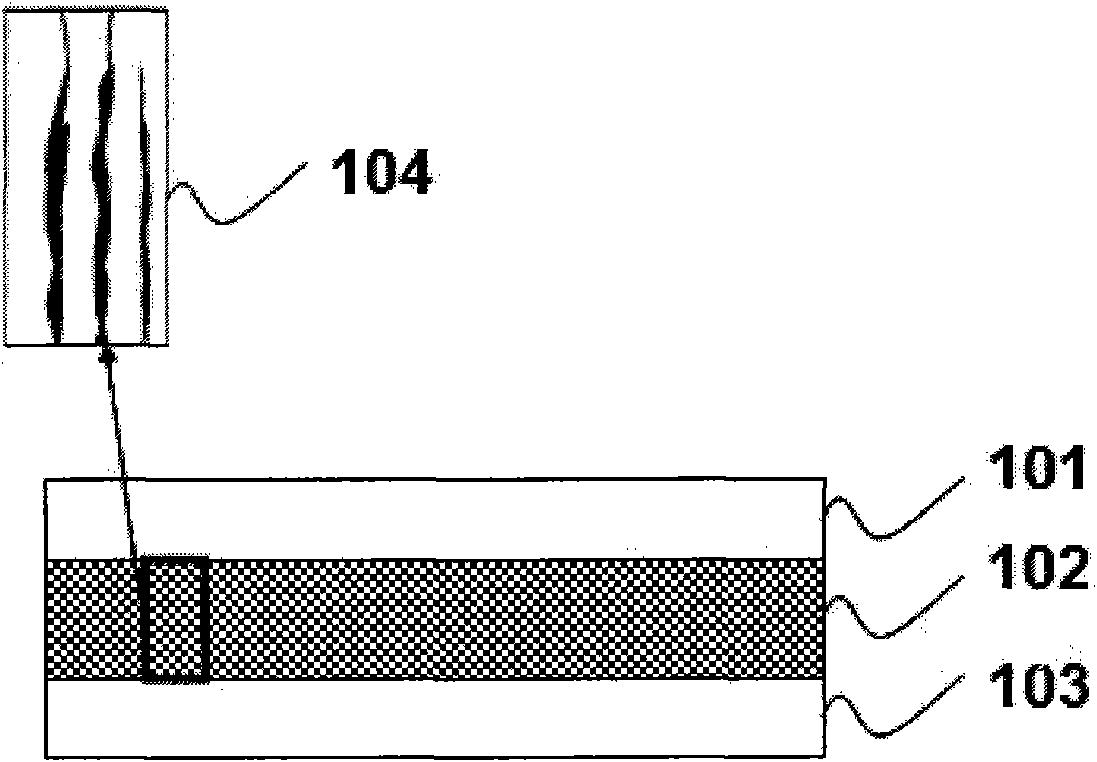

[0027] In this example, the storage unit of the novel ferroelectric oxide / semiconductor compound thin film diode resistive variable memory is as follows: figure 1 As shown, it includes substrate and bottom electrode 103 (strontium ruthenate / strontium titanate), ferroelectric oxide material (bismuth ferrite) / semiconductor (ferrous oxide) composite functional layer 102, top electrode (Pt, Au) 101.

[0028] The above-mentioned device is prepared by the following method:

[0029] 1) With the (100) direction single crystal strontium titanate as the substrate, the bottom electrode of strontium ruthenate (thickness is 10nm-150nm) is grown by pulsed laser deposition (PLD).

[0030] 2) On the above substrate, use PLD to deposit ferroelectric oxide material (bismuth ferrite) / semiconductor (ferric oxide) composite functional layer (thickness is 200nm-500nm), specifically, use trioxide in bismuth ferrite A ceramic target with an excess of 10% ferrous component.

[0031] 3) A platinum m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com