A light-induced infiltration microfluidic chip preparation method and functionalization method

A microfluidic chip and light-induced technology, applied in the fields of biochemistry and microfluidics, can solve the problems of inability to achieve multi-functionality, and achieve the effects of flexible design, reduced production cycle and cost, and reduced preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

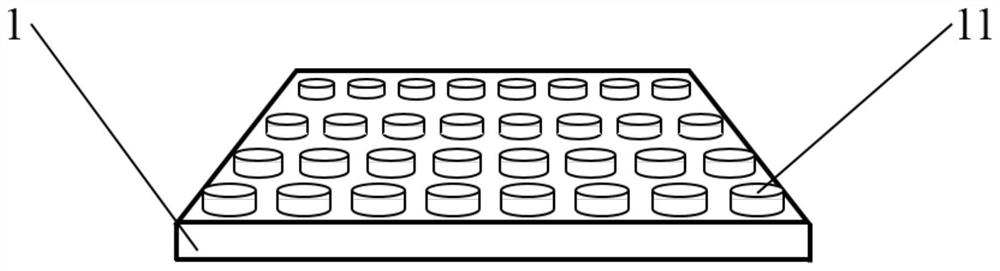

[0045] The preparation of embodiment 1 chip microstructure:

[0046] Clean the quartz chip; spin-coat photoresist on the surface of the 2x2cm quartz chip; pre-bake at 90°C for 10 minutes; use a micro-circular array mask to expose under an ultraviolet light source; remove part of the photoresist with a developer to obtain and Patterns with the same mask shape; post-baking at 150°C for 30 minutes to strengthen the film; use dry etching to obtain a micro-column array with a diameter of 8 microns on the bottom, a diameter of 10 microns on the bottom, a height of 4 microns, and an average column spacing of 3 microns Quartz chip. Such as figure 1 .

[0047] Further, the material of the micropillar array chip 1 includes: glass, quartz, polydimethylsiloxane, polymethyl methacrylate, polycarbonate, polystyrene, polyethylene, polypropylene and the like.

[0048] Further, the shape of the microarray unit 11 includes various shapes such as cylinder, rectangle, triangle, wing, streamlin...

Embodiment 2

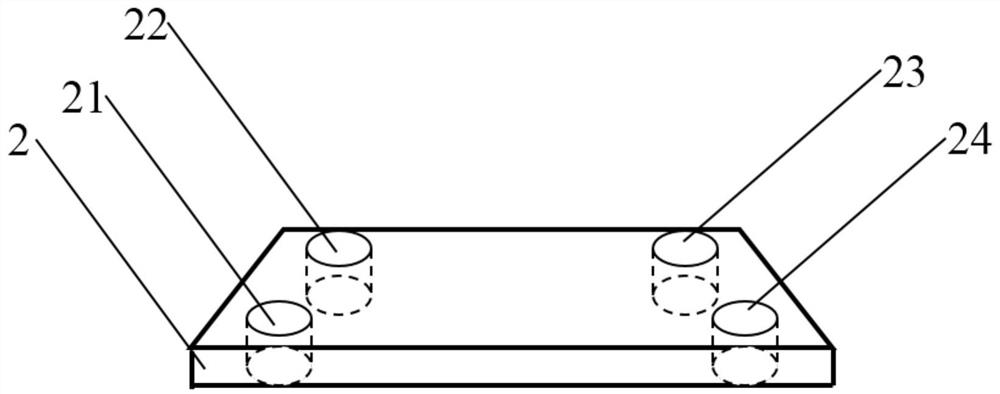

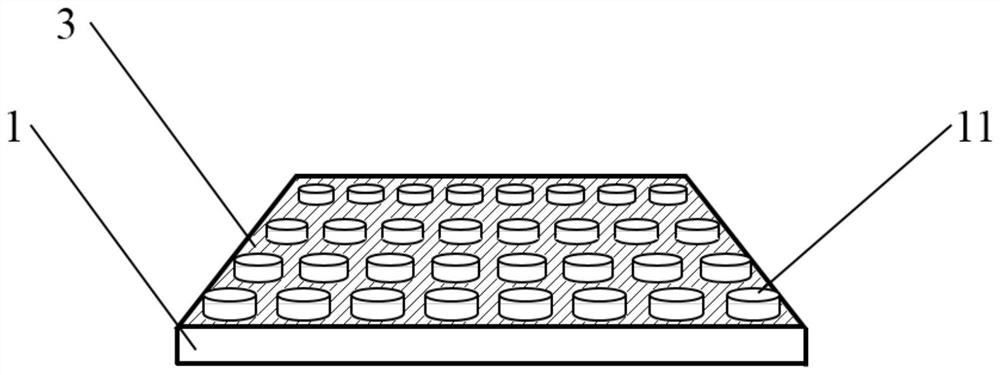

[0051] Example 2 Interface modification of light-induced materials

[0052] Use an atomic layer deposition system to deposit a zinc oxide film on the surface of the microarray chip 1 and the flat hole chip 2, such as image 3 and Figure 4 .

[0053] Further, the interface modification materials include organic light-induced materials azobenzenes and spiropyrans, and inorganic light-induced materials such as zinc oxide and titanium dioxide.

Embodiment 3

[0054] Example 3 Response and recovery of light-induced materials

[0055] Contact and seal the coated side of the two chips into a complete chip, such as Figure 5 .

[0056] A photomask 62 is placed between the sealed complete chip and an ultraviolet light source 61 with a wavelength of 365 nm and a light intensity of 145 mW / cm2. Align the chip with the mask and expose for 5 minutes, as Figure 6 . Pure water is injected from the hole at one end of the exposure area to wet the exposure area 63 to form a fluid channel.

[0057] The hydrophobicity of the two chips is restored by heat treatment, black box placement, visible light irradiation, etc., so as to realize the erasure of the fluid channel.

[0058] Various patterns and multifunctional chip functions can be realized through photomask exposure (62), including various microfluidic chip patterns such as linear, cross, H, Y, and Christmas tree shapes. During the exposure process: the wavelength of the ultraviolet light s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com