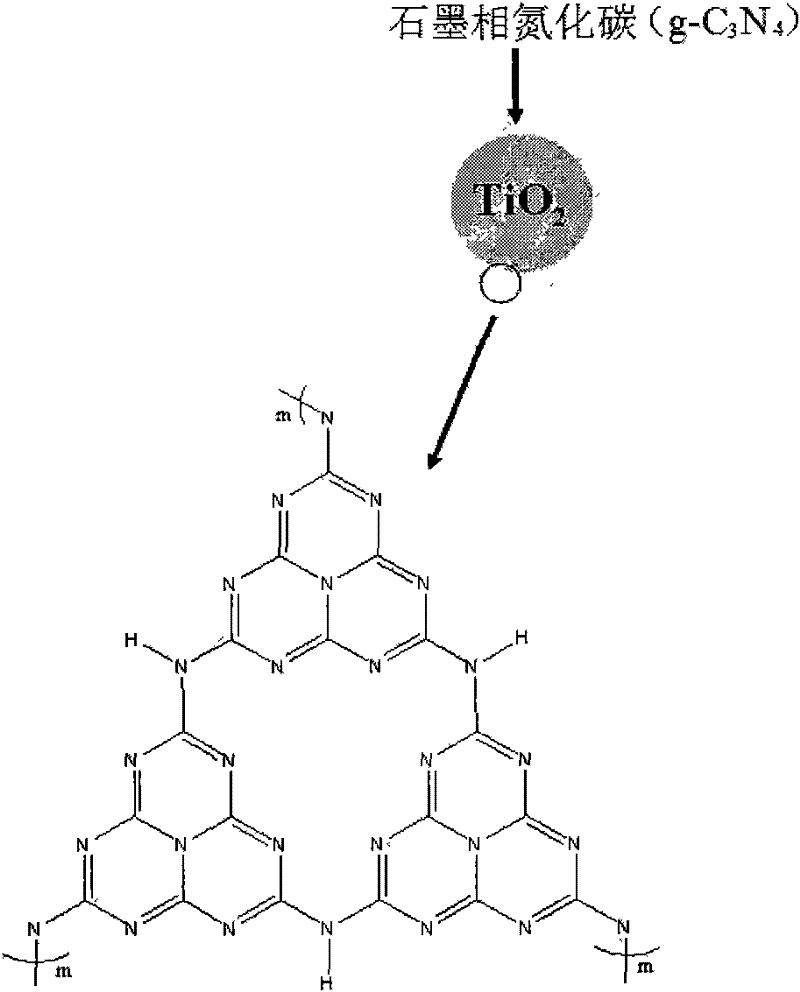

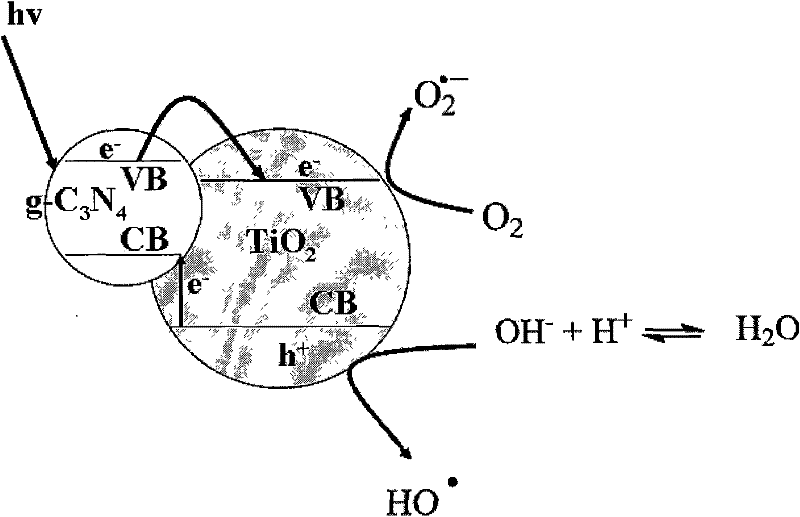

TiO2@ graphite phase carbon nitride heterojunction composite photocatalyst and preparation method thereof

A technology of graphite phase carbon nitride and compound light, which is applied in the field of photocatalysis, can solve the problems of unstable photocatalytic reaction, and achieve the effects of simple preparation process, improved chemical stability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

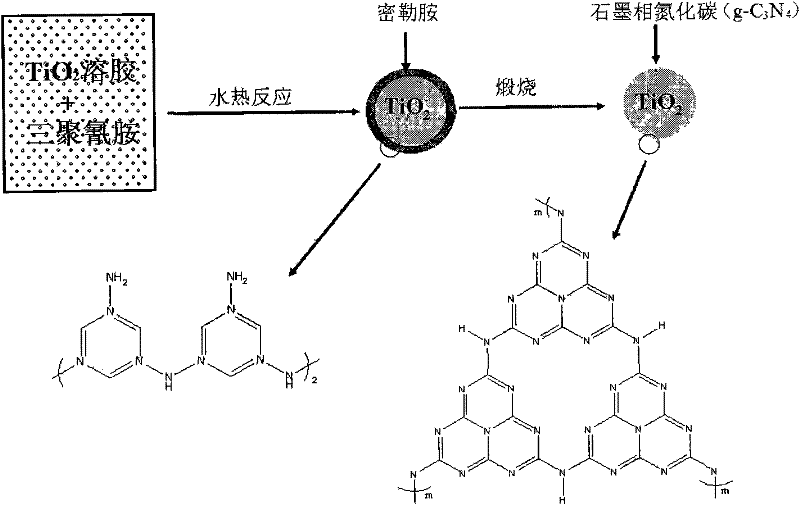

Embodiment 1

[0034] Add 0.56g melamine to 70mlTiO 2 The sol was stirred and dissolved, ultrasonicated for 10 minutes, then placed in a 100°C hydrothermal reaction vessel, kept at 180°C for 6h, then cooled to room temperature naturally, centrifuged and washed with distilled water for 5 times, vacuum-dried at 80°C for 12h, and then heat-treated at 550°C 4h, TiO is produced 2 Graphite phase carbon nitride heterojunction composite photocatalyst. X-ray diffraction tests showed that, if Figure 4 Shown: TiO 2 The crystal form is anatase. According to Scherrer's formula, the crystal grain is about 5nm, and the carbon nitride is graphite phase. High-resolution transmission electron microscopy results showed that Image 6 Shown: The catalyst is a core-shell structure, and the core is TiO 2 Nanoparticles, the particle size is about 5nm, the shell is carbon nitride, and the thickness is about 2nm.

Embodiment 2

[0036] Add 0.56g melamine to 70mlTiO 2 The sol was stirred and dissolved, ultrasonicated for 10 minutes, then put into a 100°C hydrothermal reaction vessel, kept at 200°C for 6h, then cooled to room temperature naturally, centrifuged and washed with distilled water for 5 times, vacuum-dried at 80°C for 12h, and then heat-treated at 550°C 4h, TiO is produced 2 Graphite phase carbon nitride heterojunction composite photocatalyst. X-ray diffraction tests showed that, if Figure 7 Shown: TiO 2The crystal form is anatase. According to Scherrer's formula, the crystal grain is about 6.2nm, and the carbon nitride is graphite phase. High-resolution transmission electron microscopy results showed that Figure 8 Shown: The catalyst is a core-shell structure, and the core is TiO 2 Nanoparticles, the particle size is about 6nm, the shell is carbon nitride, and the thickness is about 2nm. UV-Vis Diffuse Reflectance Spectroscopy ( Figure 9 ) shows that the composite photocatalyst has...

Embodiment 3

[0038] Add 0.84g melamine to 70ml TiO 2 The sol was stirred and dissolved, ultrasonicated for 10 minutes, then put into a 100°C hydrothermal reaction vessel, kept at 200°C for 6h, then cooled to room temperature naturally, centrifuged and washed with distilled water for 5 times, vacuum-dried at 80°C for 12h, and then heat-treated at 550°C 4h, TiO is produced 2 Graphite phase carbon nitride heterojunction composite photocatalyst. X-ray diffraction test shows that: TiO 2 The crystal form is anatase. According to Scherrer's formula, the crystal grain is about 5.2nm, and the carbon nitride is graphite phase. The results of high-resolution transmission electron microscopy show that the catalyst has a core-shell structure, and the core is TiO 2 Nanoparticles, the particle size is about 5nm, the shell is carbon nitride, and the thickness is about 2nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com